Preparation method for biomass seedling growing plate

A seedling raising board and biomass technology, applied in the field of seedling raising substrate, can solve problems such as unfavorable sustainable and healthy development of agriculture, no breakthrough in component formula, waste of resources, etc., achieve harmless recycling and improve transplanting survival rate , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

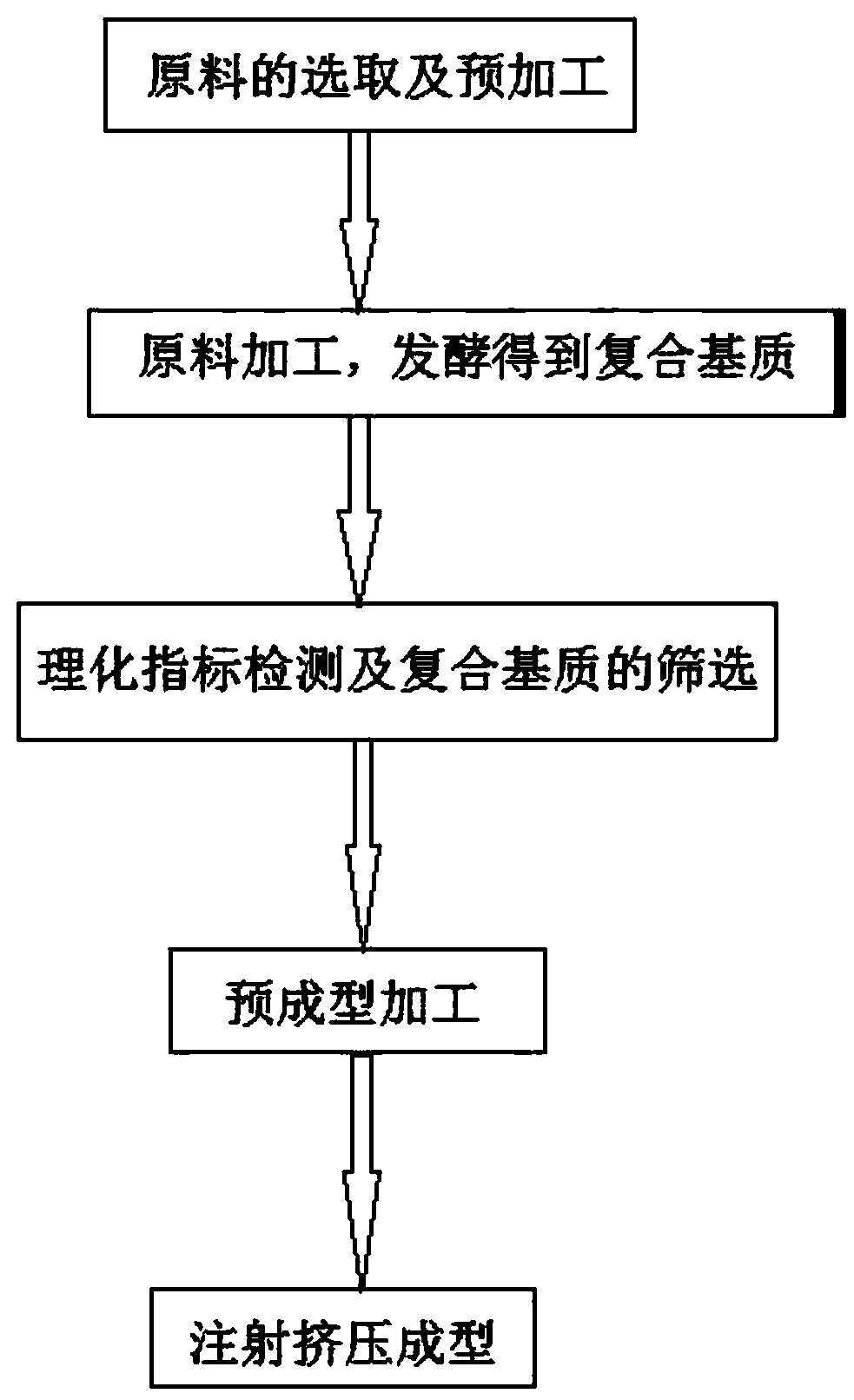

[0027] Such as figure 1 Shown, a kind of preparation method of biomass seedling raising plate, it may further comprise the steps:

[0028] S1. Selection and pre-processing of raw materials: Select crop by-products as raw materials and crush them to a particle size of 3-5mm; crop by-products can be straw, mushroom dregs, coconut peat, bagasse and reeds, etc.;

[0029] S2, raw material processing, fermentation to obtain composite matrix: 60wt% of crushed crop by-products, 8wt% of vermiculite, 5wt% of basic fertilizer, 5wt% of fulvic acid, 20wt% of polylactic acid and 2wt% of wetting agent After mixing evenly, add 0.2wt% yeast agent to carry out aerobic fermentation. The yeast agent is one or more of photosynthetic bacteria, acetic acid bacteria, actinomycetes, bacillus, saccharomyces and filamentous fungi, and the fermentation temperature is 20 ~25°C, fermentation time: 3~7 days in summer, 7~10 days in spring and autumn, 10~20 days in winter, after fermentation and decomposing,...

Embodiment 1

[0037] The preparation method of the biomass seedling board for planting vegetable seedlings comprises the following steps:

[0038] S1. Raw material selection and pre-processing: select agricultural by-products as raw materials and crush them to a particle size of 3-5 mm. Raw materials can be straws such as young seedlings or corn, or mushroom dregs, coconut bran, bagasse or reeds, etc.;

[0039] S2, raw material processing, fermentation to obtain composite matrix: mix 60wt% of crushed crop by-products, 8wt% of vermiculite, 5wt% of basic fertilizer, 5wt% of fulvic acid, 20wt% of polylactic acid and 2wt% of sodium hypochlorite After uniformity, add 0.2wt% of yeast agent to carry out aerobic fermentation. The yeast agent is one or more of photosynthetic bacteria, acetic acid bacteria, actinomycetes, bacillus, saccharomyces and filamentous fungi, and the fermentation temperature is 20-20℃. 25°C, fermentation time: 3-7 days in summer, 7-10 days in spring and autumn, and 10-20 day...

Embodiment 2

[0049] The seedling cultivation of capsicum biomass seedling raising board in early spring in the protected area first prepares the seedling raising board, which comprises the following steps:

[0050] S1. Raw material selection and pre-processing: select agricultural by-products as raw materials and crush them to a particle size of 3-5 mm. Raw materials can be straws such as young seedlings or corn, or mushroom dregs, coconut bran, bagasse or reeds, etc.;

[0051] S2, raw material processing, fermentation to obtain composite matrix: mix 60wt% of crushed crop by-products, 8wt% of vermiculite, 5wt% of basic fertilizer, 5wt% of fulvic acid, 20wt% of polylactic acid and 2wt% of sodium hypochlorite After uniformity, add 0.2wt% of yeast agent to carry out aerobic fermentation. The yeast agent is one or more of photosynthetic bacteria, acetic acid bacteria, actinomycetes, bacillus, saccharomyces and filamentous fungi, and the fermentation temperature is 20-20℃. 25°C, the fermentatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper caliber | aaaaa | aaaaa |

| Lower caliber | aaaaa | aaaaa |

| Upper caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com