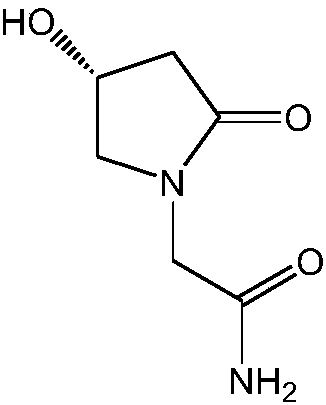

Dextrorotatory oxiracetam soluble oral membrane and preparation method thereof

A technology of oral instant film and co-solvent, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, nervous system diseases, etc., and can solve the problems of low drug loading, difficult control of disintegration time and tensile strength, and constraints Problems such as the development and application of oral instant film, to achieve the effect of simple preparation method, improved bioavailability, and avoiding elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

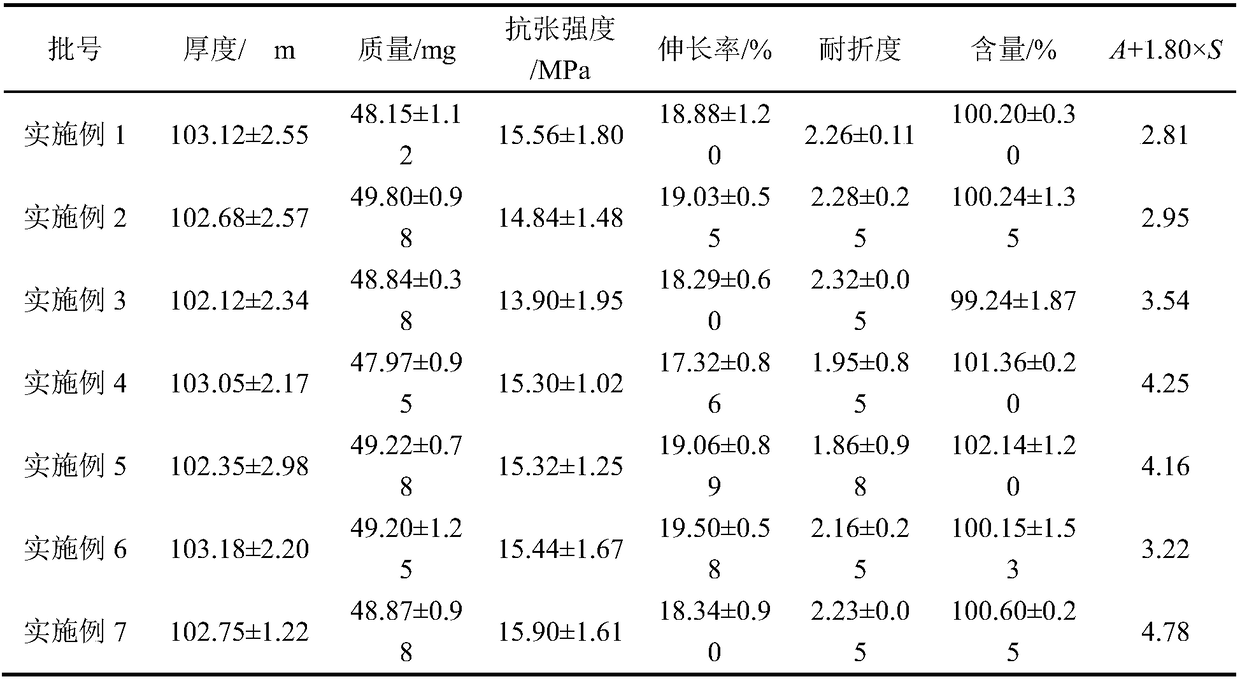

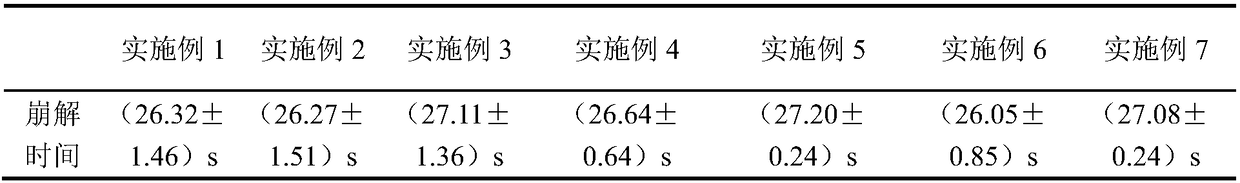

Examples

Embodiment 1

[0037] Mix 48 parts of dexoxiracetam, 30 parts of maltodextrin, 10 parts of ethyl cellulose, 2 parts of propylene glycol, 6 parts of dibutyl phthalate, 3 parts of citric acid, and 1 part of fructose, and mix well , sent to the hot-melt zone through the feed zone of the hot-melt film laminator, hot-melted at 80-85°C, the molten mixture is continuously output through the metering zone, poured into the mold, and forms a film after cooling.

Embodiment 2

[0039] Mix 40 parts of dexoxiracetam, 24 parts of maltodextrin, 16 parts of polyoxyethylene, 8 parts of pectin, 6 parts of glycerin, 3 parts of triethyl citrate, 2 parts of malic acid, and 1 part of sucrose Finally, it is sent to the hot-melt zone through the feeding zone of the hot-melt film laminator, and is melted at 85-90°C. The molten mixture is continuously output through the metering zone, poured into the mold, and forms a film after cooling.

Embodiment 3

[0041] Mix 55 parts of dexoxiracetam, 25 parts of maltodextrin, 5 parts of ethyl cellulose, 4 parts of propylene glycol, 4 parts of dibutyl phthalate, 5 parts of lactic acid, 2 parts of aspartame, mix After uniformity, it is sent to the hot-melt zone through the feeding zone of the hot-melt film laminator, and is melted at 95-98°C. The molten mixture is continuously output through the metering zone, poured into the mold, and forms a film after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com