Cooking-resistant suction nozzle and production method thereof

A production method and cooking-resistant technology, applied in the field of materials and processing, can solve the problems of inability to withstand high temperature, use, etc., and achieve the effect of ensuring sealing performance, obvious gram weight, and improving market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

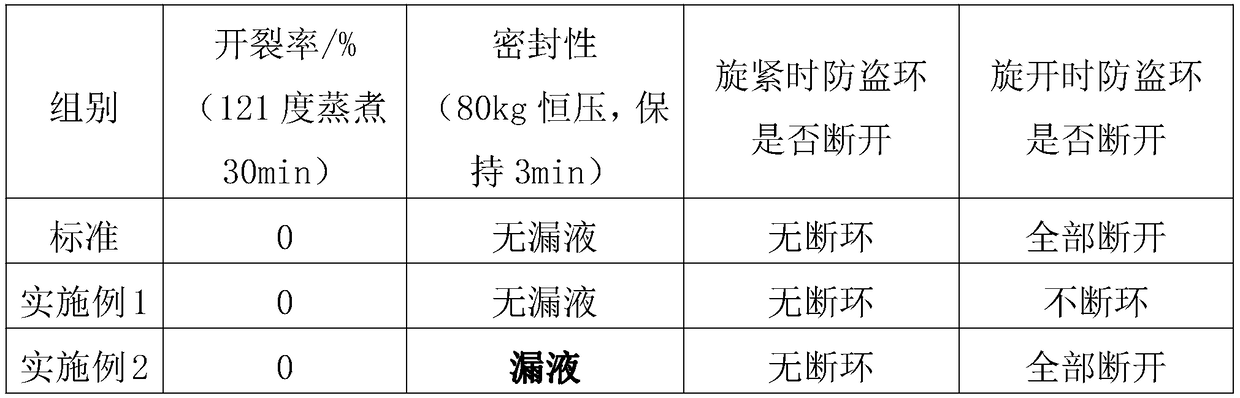

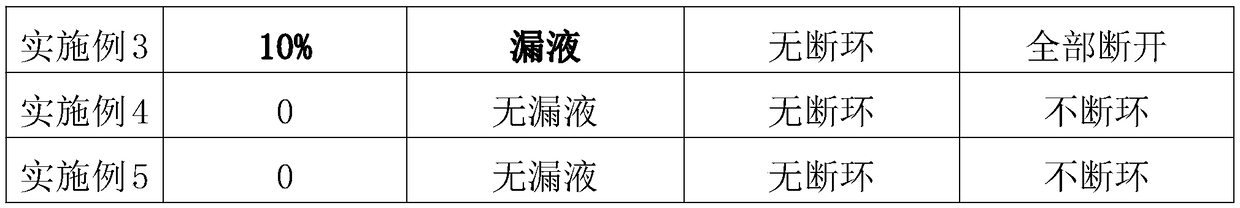

Examples

Embodiment 1

[0023] The production method of the suction nozzle comprises the steps:

[0024] S1. Add the pelletized polypropylene copolymer and the color masterbatch into the barrel of the injection molding machine according to the mass ratio of 100:2 and mix them evenly, and heat to 210 °C to reach a molten state;

[0025] S2. Inject the molten pellets into the mold cavity in four stages and hold the pressure for 1.8 seconds. The injection pressure of the first stage is 85bar, the injection pressure of the second stage is 75bar, the injection pressure of the third stage is 65bar, and the injection pressure of the fourth stage is 60bar. The four-stage injection time is 3.5 seconds respectively;

[0026] S3. After cooling for 6 seconds, the film is removed by rotating to obtain a nozzle product.

Embodiment 2

[0028] The production method of the suction nozzle comprises the steps:

[0029] S1. Add the pellets of homopolypropylene and the color masterbatch into the barrel of the injection molding machine according to the mass ratio of 100:2 and mix them evenly, and heat to 210 ° C to reach a molten state;

[0030] S2. Inject the molten pellets into the mold cavity in four stages and hold the pressure for 0.5 seconds. The injection pressure of the first stage is 85bar, the injection pressure of the second stage is 75bar, the injection pressure of the third stage is 65bar, and the injection pressure of the fourth stage is 60bar. The four-stage injection time is 3.5 seconds respectively;

[0031] S3. After cooling for 6 seconds, the film is removed by rotating to obtain a nozzle product.

Embodiment 3

[0033] The production method of the suction nozzle comprises the steps:

[0034] S1. Add the pellets of homopolypropylene and the color masterbatch into the barrel of the injection molding machine according to the mass ratio of 100:6 to mix evenly, and heat up to 210 ° C to reach a molten state;

[0035] S2. Inject the molten pellets into the mold cavity in four stages and hold the pressure for 1.8 seconds. The injection pressure of the first stage is 85bar, the injection pressure of the second stage is 75bar, the injection pressure of the third stage is 65bar, and the injection pressure of the fourth stage is 60bar. The four-stage injection time is 3.5 seconds respectively;

[0036] S3. After cooling for 6 seconds, the film is removed by rotating to obtain a nozzle product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com