Graphene-containing heating board for building heating and preparation method thereof

A graphene and graphene-coated technology, which is applied in the field of building materials, can solve the problems of easy peeling off of conductive coatings and uneven heating, and achieve stable heating, safe use, and good heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

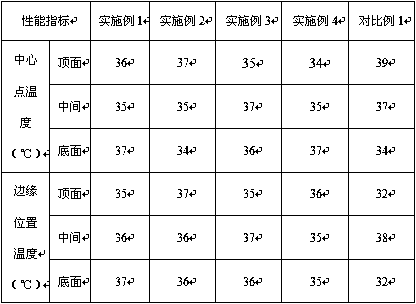

Examples

Embodiment 1

[0027] A preparation method of a graphene-containing heating plate for building heating, comprising the following steps:

[0028] (1) Mix aluminum sulfate solution, silicic acid solution and hydroxylated glass fiber, so that aluminum sulfate and silicic acid solution are adsorbed on the surface of the inorganic fiber, and then add graphene oxide to mix, so that graphene oxide is coated on the modified inorganic fiber Fiber surface, add reducing agent then, graphene oxide is reduced to graphene, dry, make graphene coated inorganic fiber conductive material; Reducing agent is hydrazine hydrate; The weight parts of each raw material is, aluminum sulfate solution 6 weight parts, 1 part by weight of silicic acid solution, 77 parts by weight of inorganic fiber, 10 parts by weight of graphene oxide, and 1 part by weight of reducing agent; wherein the mass concentration of aluminum sulfate solution is 8%; the mass concentration of silicic acid solution is 25%.

[0029] (2) Mix the gra...

Embodiment 2

[0033] A preparation method of a graphene-containing heating plate for building heating, comprising the following steps:

[0034] (1) Mix aluminum sulfate solution, silicic acid solution and hydroxylated calcium silicate fiber, so that aluminum sulfate and silicic acid solution are adsorbed on the surface of the inorganic fiber, and then add graphene oxide to mix, so that graphene oxide is coated on the modified surface. Then add reducing agent to reduce graphene oxide to graphene and dry to obtain graphene-coated inorganic fiber conductive material; reducing agent is hydrazine hydrate; the parts by weight of each raw material are 6 weight of aluminum sulfate solution parts, 2 parts by weight of silicic acid solution, 85 parts by weight of inorganic fiber, 15 parts by weight of graphene oxide, and 2 parts by weight of reducing agent; wherein the mass concentration of aluminum sulfate solution is 8%; the mass concentration of silicic acid solution is 25%.

[0035] (2) Mix the g...

Embodiment 3

[0039] A preparation method of a graphene-containing heating plate for building heating, comprising the following steps:

[0040] (1) Mix aluminum sulfate solution, silicic acid solution and hydroxylated glass fiber, so that aluminum sulfate and silicic acid solution are adsorbed on the surface of the inorganic fiber, and then add graphene oxide to mix, so that graphene oxide is coated on the modified inorganic fiber Fiber surface, then add reducing agent, graphene oxide is reduced to graphene, dry, and make graphene coated inorganic fiber conductive material; Reducing agent is hydrazine hydrate; The weight parts of each raw material is, aluminum sulfate solution 4 weight parts, 1 part by weight of silicic acid solution, 77 parts by weight of inorganic fiber, 10 parts by weight of graphene oxide, and 1 part by weight of reducing agent; wherein the mass concentration of aluminum sulfate solution is 8%; the mass concentration of silicic acid solution is 25%.

[0041] (2) Mix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com