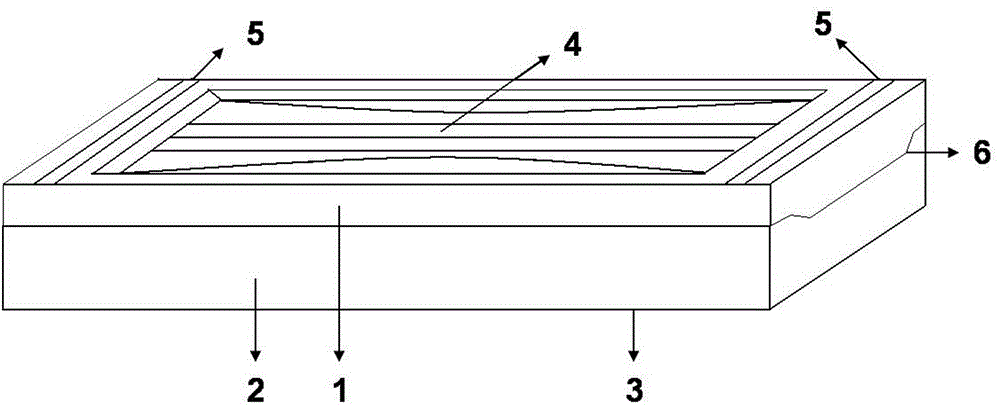

C/h-BN composite evaporation boat used for film coating and manufacturing method thereof

The technology of evaporation boat and composite block is applied in the field of evaporation element for vacuum evaporation of aluminized film and its production, which can solve the problems of shortening the service life of the evaporation boat, changing the resistance of the evaporation boat, uneven corrosion of the evaporation boat, etc., so as to improve the high temperature Antioxidant ability, reducing thermal radiation heat loss, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The C / h-BN composite evaporating boat used for the coating described in this embodiment, the particles are 100 to 200 mesh raw material powder, mixed with weight percentage BN: 94%, CaO: 5%, B2O3: 1%;

[0025] Process the upper and lower surfaces of a graphite block with a thickness of 8mm to obtain a suitable joint form, then perform sandblasting on the upper and lower surfaces, and then coat a mixture of phenolic resin, graphite, and cubic boron nitride, with a mass percentage of 1:0.5: 0.5;

[0026] The mixed powder and the treated graphite block are placed alternately in the high-temperature furnace mold according to the thickness of 2:1, a total of 6 layers each, and placed in a high-temperature vacuum furnace for hot-press sintering.

[0027] When the pressure in the high-temperature vacuum furnace is less than 0.2Pa, start to feed N2 into the furnace, and pressurize to 5MPa at a temperature of 150°C; when the temperature rises to 1100°C, pressurize to 10MPa; The...

Embodiment 2

[0031] The C / h-BN composite evaporating boat used for the coating described in this embodiment, the particles are 100-200 mesh raw material powder, mixed with weight percentage BN: 96%, CaO: 3%, B2O3: 1%;

[0032] Process the upper and lower surfaces of graphite blocks with a thickness of 8mm to obtain a suitable joint form, and then perform sandblasting on the upper and lower surfaces;

[0033] Mix medium-temperature coal tar pitch powder and cubic boron nitride powder with particles of 100-200 mesh at a mass percentage of 1:0.5;

[0034]Coat or spread the mixed BN powder and coal tar pitch / boron nitride mixture powder on the surface of the graphite block, first spread a layer of coal tar pitch / boron nitride mixture powder, then spread a layer of BN powder mixture, and then According to the thickness of 100:1:200, it is laid layer by layer into the high-temperature furnace mold, and a total of 6 layers are hot-pressed and sintered.

[0035] When the pressure in the high-temp...

Embodiment 3

[0039] The C / h-BN composite evaporation boat for coating described in this embodiment, the particles are 100-200 mesh raw material powder, with weight percentage BN: 51%, AlN: 45%, CaO: 3%, B2O3: 1% to mix;

[0040] Process the upper and lower surfaces of graphite blocks with a thickness of 8mm to obtain a suitable joint form, and then perform sandblasting on the upper and lower surfaces;

[0041] Mix medium-temperature coal tar pitch powder and cubic boron nitride powder with particles of 100-200 mesh at a mass percentage of 1:0.5;

[0042] Coat or spread the mixed BN powder and coal tar pitch powder mixture on the surface of the graphite block, first spread a layer of coal tar pitch powder mixture, and then spread a layer of BN powder mixture, in turn according to the thickness of 100:1:200 Lay layer by layer into the high-temperature furnace mold, and a total of 6 layers are hot-pressed and sintered.

[0043] When the pressure in the high-temperature vacuum furnace is les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com