Stain and water resistant stone-like lacquer and preparation method thereof

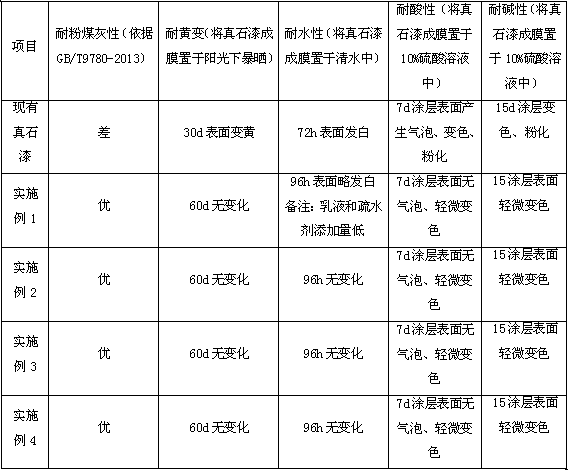

A technology of real stone paint and stain resistance, applied in the field of building materials coatings, can solve the problems of poor stain resistance and poor water resistance of real stone paint, and achieve the effect of hard and smooth surface, good film-forming adhesion, and strong acid and alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A real stone paint consisting of the following ingredients:

[0027] water 100g

[0028] Silicone Modified Acrylic Emulsion 120g

[0029] Coalescing agent (lauryl alcohol) 8g

[0030] Ethylene glycol 6g

[0031] pH regulator (Dow AMP-95) 1g

[0032] Hydrophobic agent (Momentive WMS, USA) 5g

[0033] Preservative (Sol MBS) 0.5g

[0034] Hydroxyethyl Cellulose Ether 1g

[0035] Artificial sintered sand 750g

[0036] The preparation method of above-mentioned genuine stone paint is as follows:

[0037] Step 1. Add 100g of water into the mixing tank, add 1g of hydroxyethyl cellulose ether under stirring at 900rpm, and stir for a period of time for 15min.

[0038] Step 2: Add 1g of pH regulator, 8g of lauryl alcohol, 6g of ethylene glycol, 120g of silicone-modified acrylic emulsion, 0.5g of preservative, and 5g of water-repelling agent to the mixing tank successively under stirring at 500rpm, and stir for 15min to obtain Real stone paint paste.

[0039] Step 3. Tran...

Embodiment 2

[0041] A real stone paint consisting of the following ingredients:

[0042] water 110g

[0043] Silicone Modified Acrylic Emulsion 140g

[0044] Coalescing agent (lauryl alcohol) 10g

[0045] Ethylene glycol 4g

[0046] pH regulator (Dow AMP-95) 1.5g

[0047] Hydrophobic agent (Momentive WMS, USA) 8.5g

[0048] Preservative (Sol MBS) 1g

[0049] Hydroxyethyl Cellulose Ether 2g

[0050] Artificial sintered sand 700g

[0051] The preparation method of above-mentioned genuine stone paint is as follows:

[0052] Step 1. Add 110 g of water into the mixing tank, add 2 g of hydroxyethyl cellulose ether under stirring at 900 rpm, and stir for a period of time for 13 minutes.

[0053] Step 2: Add 1.5g of pH adjuster, 10g of lauryl alcohol, 4g of ethylene glycol, 140g of silicone-modified acrylic emulsion, 1g of preservative, and 8.5g of hydrophobic agent into the mixing tank in turn under stirring at 600rpm, and stir for 18 minutes. Get real stone paint slurry.

[0054] Step ...

Embodiment 3

[0056] A real stone paint consisting of the following ingredients:

[0057] water 120g

[0058] Silicone Modified Acrylic Emulsion 130g

[0059] Coalescing agent (lauryl alcohol) 8g

[0060] Ethylene glycol 6g

[0061] pH regulator (Dow AMP-95) 1.2g

[0062] Hydrophobic agent (Momentive WMS, USA) 7g

[0063] Preservative (Sol MBS) 0.75g

[0064] Hydroxyethyl Cellulose Ether 1g

[0065] Artificial sintered sand 750g

[0066] The preparation method of above-mentioned genuine stone paint is as follows:

[0067] Step 1. Add 120g of water into the mixing tank, add 1g of hydroxyethyl cellulose ether under stirring at 100rpm, and stir for a period of time for 10min.

[0068] Step 2: Add 1.2g of pH adjuster, 8g of lauryl alcohol, 6g of ethylene glycol, 130g of silicone-modified acrylic emulsion, 0.75g of preservative, and 7g of hydrophobic agent into the mixing tank in sequence, and stir for 15 minutes. Get real stone paint slurry.

[0069] Step 3. Transfer the real stone pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com