Archaized brick with low sintering temperature, low radioactivity and ultrawhite whole body, green body and preparation method of green body

A technology with firing temperature and low radioactivity, which is applied in the field of low-radiation full-body ultra-white antique bricks, green body and its preparation, and low firing temperature, which can solve the problems of lower firing temperature, high content, production performance and quality of antique bricks etc. to achieve the effects of lowering the firing temperature, optimizing process performance, and excellent ultra-white performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

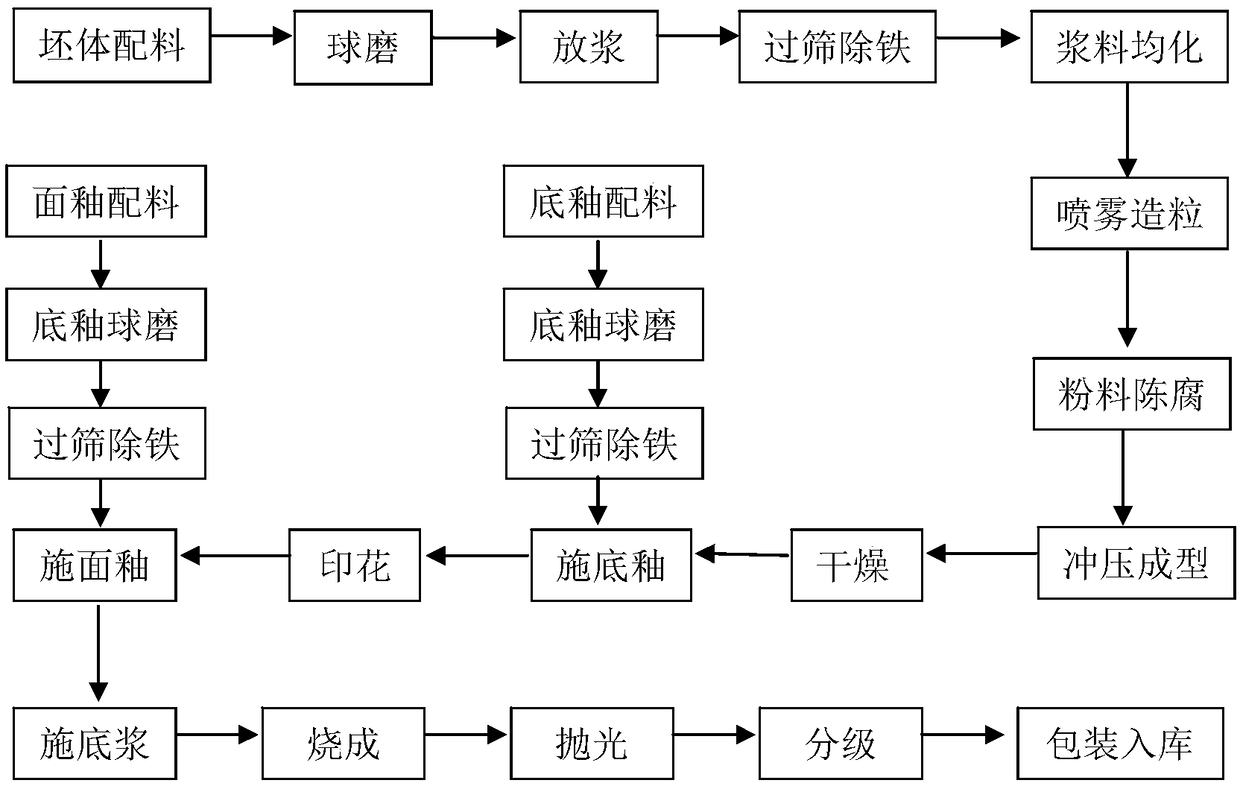

[0067] A method for preparing a low-firing temperature, low-radioactive full-body ultra-white antique brick, which includes the following steps: preparation of a green body, preparation of a bottom glaze, preparation of a surface glaze, and preparation and firing of a product, wherein:

[0068] Preparation of green body:

[0069] The chemical composition of green body is as follows table 1:

[0070] Table 1, the chemical composition list of green body (weight percent, %)

[0071] Component

SiO 2

al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na 2 o

1#

66.7

18.5

0.47

0.09

2.8

0.99

3.3

3.16

3.99

2#

67

18

0.43

0.12

2.12

1.23

3.5

3.27

4.33

3#

66.4

20.4

0.25

0.05

2.15

1.01

3.23

3.13

3.38

4#

65

21

0.6

0.05

1.5

0.5

2.85

3.5

5

5#

68

19.2

0.1

0.2

3

1.5

2.5

2.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com