Preparation method of high-adhesiveness conductive adhesive

A conductive adhesive, high-adhesion technology, used in the preparation of animal glue or gelatin, conductive adhesives, adhesives, etc., can solve the problems of decreased conductivity, poor adhesion, etc. The effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

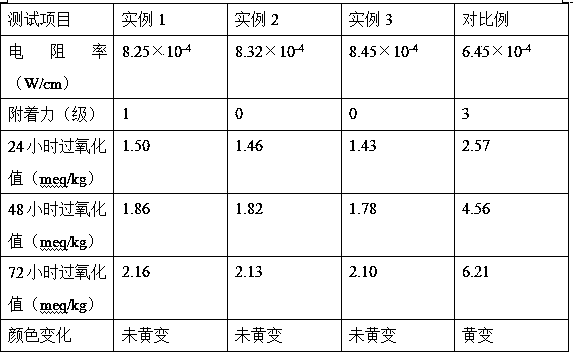

Examples

Embodiment Construction

[0023] Weigh 500-600g bamboo slices, put them into the dryer and dry them for 5-6 hours, transfer the dried bamboo slices into the steam explosion tank of the steam explosion device, preheat the steam to 240-260°C, and pass it into the steam explosion tank. In the tank, stop feeding steam until the pressure reaches 3.6-3.8MPa, and after maintaining the pressure for 30-50s, open the discharge valve of the steam explosion tank, so that the material in the steam explosion tank is injected into the receiving tank instantaneously, and the material in the receiving tank is collected to obtain Steam explosion wet material; mix the above steam explosion wet material with a dopamine solution with a mass fraction of 10-15%, put it into a beaker, stir and react for 2-3 hours, filter and separate to obtain a reaction filter residue, and mix the reaction filter residue and a mass fraction of 15-15% The 18% ferric chloride solution is mixed according to the mass ratio of 1:10, then continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com