Slow-release type composite cold storage agent

A cold storage agent and slow-release technology, which is applied in the field of agricultural biotechnology, can solve the problems of low temperature storage product quality and safety impact, affect the use effect of cold storage agent, reduce the low temperature maintenance time, etc., so as to prolong the release time of cold energy and improve the phase transition The effect of slow release of latent heat and cold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

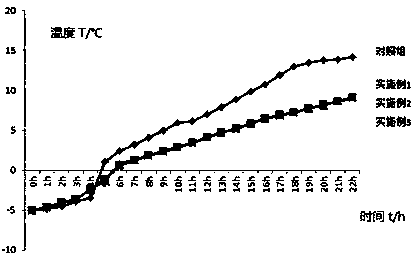

Examples

Embodiment 1

[0038]A slow-release composite cold storage agent. According to the mass parts, the components of the composite cold storage agent include: 7 parts of temperature-control slow-release agent, 3 parts of calcium chloride, 2 parts of ammonium chloride, 1 part of mannitol, polyvinyl alcohol 5 parts, 0.5 parts of thickener, 1 part of sodium borate, 0.2 parts of preservative, 85 parts of water.

[0039] Wherein, thickener selects guar gum for use.

[0040] The preservative is potassium sorbate.

[0041] The preparation method of the cold storage agent provided by the present embodiment is:

[0042] According to the number of parts by mass, the temperature-controlled slow-release agent, calcium chloride, ammonium chloride and sodium borate were added to the mixer and mixed uniformly in advance to obtain the solid phase components. After the water was heated to 35°C, mannitol, Mix and disperse polyvinyl alcohol and preservative to obtain liquid phase components, add solid phase comp...

Embodiment 2

[0044] A slow-release composite cold storage agent. According to the mass parts, the components of the composite cold storage agent include: 12 parts of temperature-control slow-release agent, 5 parts of calcium chloride, 4 parts of ammonium chloride, 5 parts of mannitol, polyvinyl alcohol 8 parts, thickener 1.2 parts, sodium borate 2 parts, preservative 0.5 parts, water 90 parts.

[0045] Wherein, the thickener selects xanthan gum for use.

[0046] The preservative is an equal mass ratio mixture of potassium sorbate and sodium benzoate.

[0047] The preparation method of the cold storage agent provided by the present embodiment is:

[0048] According to the number of parts by mass, add the temperature-controlled slow-release agent, calcium chloride, ammonium chloride and sodium borate into the mixer and pre-mix evenly to obtain the solid phase components. After heating the water to 40 ° C, add mannitol, Mix and disperse polyvinyl alcohol and preservative to obtain liquid ph...

Embodiment 3

[0050] A slow-release composite cold storage agent. According to the mass parts, the components of the composite cold storage agent include: 10 parts of temperature-control slow-release agent, 4 parts of calcium chloride, 3 parts of ammonium chloride, 3 parts of mannitol, polyvinyl alcohol 6.5 parts, 0.8 parts of thickener, 1.7 parts of sodium borate, 0.3 parts of preservative, 88 parts of water.

[0051] Wherein, thickener selects guar gum for use.

[0052] The preservative is a mixture of sorbic acid, sodium benzoate and natamycin in a mass ratio of 1:5:2.

[0053] The preparation method of the cold storage agent provided by the present embodiment is:

[0054] According to the number of parts by mass, the temperature-controlled slow-release agent, calcium chloride, ammonium chloride and sodium borate were added to the mixer and mixed uniformly in advance to obtain the solid phase components. After the water was heated to 37 ° C, mannitol, Mix and disperse polyvinyl alcohol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com