Preparation method of fungal Candida biofilm flow model

A biofilm and flow model technology, applied in the biological field, can solve the problems of complex operation, rarely mixed biofilm incubation, and low flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: a kind of preparation method of Candida fungus biofilm flow model

[0030] A method for preparing a fungal biofilm flow model, comprising construction of a fungal biofilm flow model device, fungal strain cultivation, fungal biofilm incubation, fungal biofilm evaluation, and scanning electron microscope detection. The specific plan is as follows.

[0031] (1) Construction of fungal biofilm flow model device

[0032] The fungal biofilm flow model device includes a beaker containing culture solution, a digital display peristaltic pump, a liquid separator (50ml) made of centrifuge tubes, and four centrifuge tubes (50ml / pc) for biofilm incubation and its stand, a beaker for the effluent.

[0033] The preparation method of the liquid separator injector is as follows: respectively punch one and a row of four 2mm holes at the relative positions of the centrifuge tube wall, when placed, one hole directly above is a liquid inlet hole, and 4 The first hole is th...

Embodiment 2

[0054] Embodiment two: a kind of preparation method of candida fungus biofilm flow model

[0055] The difference from Example 1 is that the strains are Candida albicans SC 5314 and Candida glabrataATCC64677. Candida albicans SC 5314 was donated by the School of Pharmacy, Shanghai Second Military Medical University, and Candidaglabrata ATCC64677 was provided by the First Affiliated Hospital of Anhui Medical University.

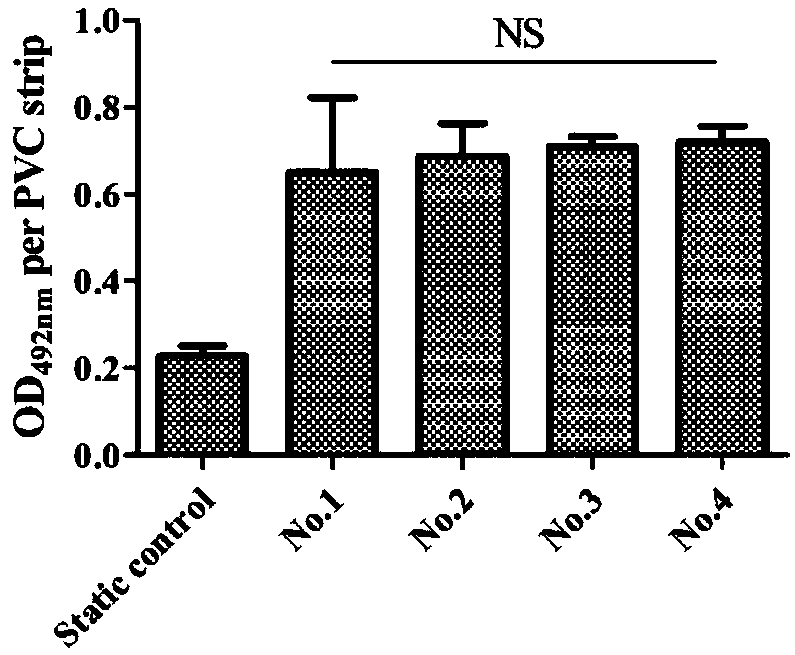

[0056] like Figure 6 As shown, under the flow regime, the stability of the flow model device after four biofilm incubation tubes were incubated for 24h with Candidaalbicans SC 5314-Candida glabrata ATCC64677 mixed biofilm was tested by XTT method. We found that the OD values (492nm) of the dissociated bacterial cells on the catheter sheet in the four incubation tubes were 0.9633±0.1829, 0.9827±0.0460, 0.9223±0.0801, 0.9710±0.0370, and there was no significant difference between them.

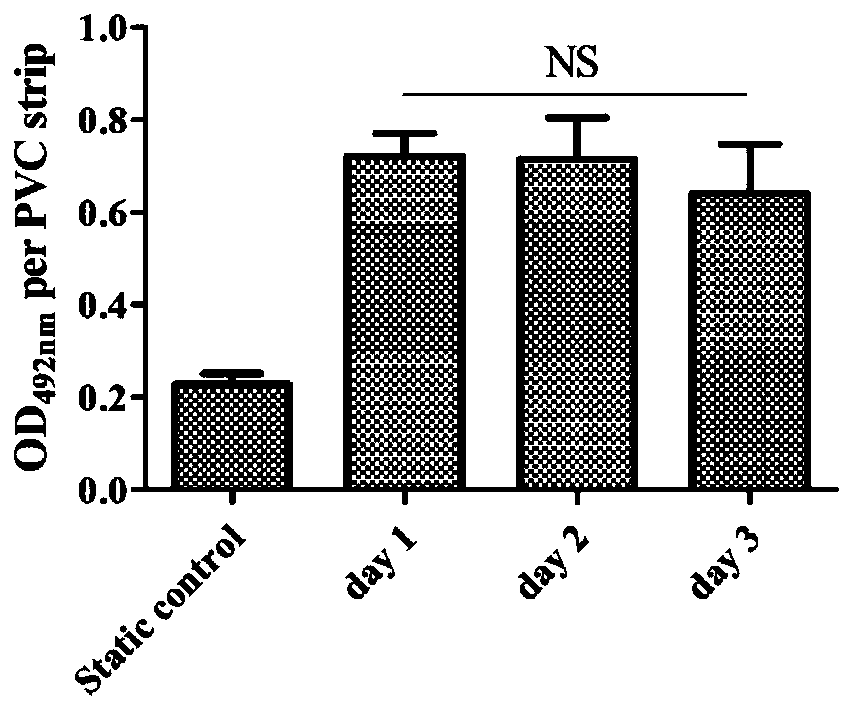

[0057] like Figure 7 As shown, under the flow state, the stability of...

Embodiment 3

[0060] Embodiment three: a kind of preparation method of Candida fungus biofilm flow model

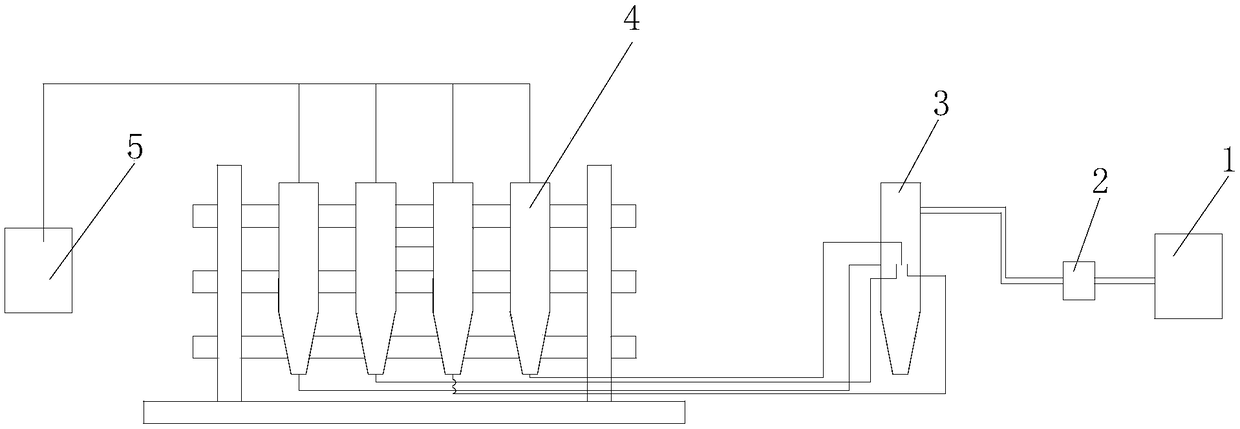

[0061] A preparation method of a Candida fungus biofilm flow model, comprising a Candida fungus biofilm flow model device, such as figure 1 As shown, the Candida fungus biofilm flow model device includes a first container 1 for containing fungal culture medium, a peristaltic pump 2, a separator 3, and four second containers for biofilm incubation. Container 4 and a third container 5 that accommodates the effluent; the liquid separator is provided with a liquid inlet, and four outlet holes are provided below the liquid inlet; the top of the second container The top hole is provided, and the bottom hole is provided with the bottom hole; the four second containers for biofilm incubation are located on the same level, and the liquid inlet hole of the liquid separator is connected with the outlet of the peristaltic pump through the pipeline. The liquid port is connected, the liquid inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com