Metal alloy with high impact resistance and preparation method thereof

A metal alloy, high impact resistance technology, applied in the field of metal alloys with high impact resistance and its preparation, can solve problems such as car damage, engine blade breakage and flying out, casualties, etc., to delay the generation and expansion, material organization Densification, strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

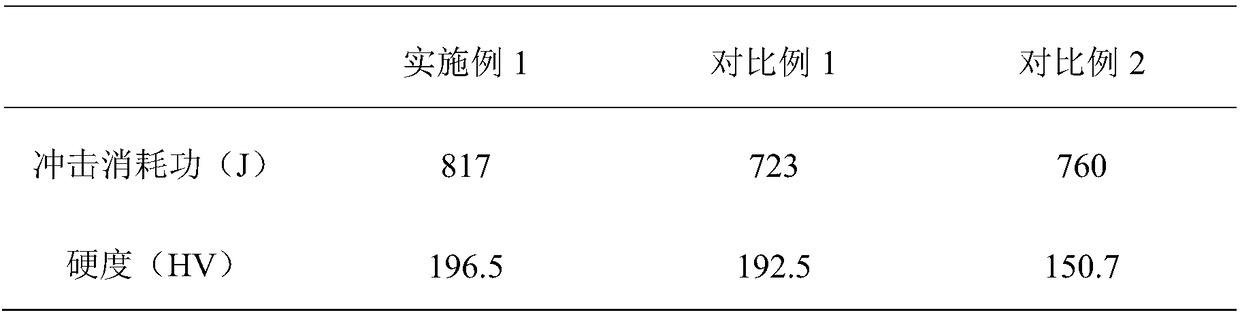

Examples

Embodiment 1

[0019] A metal alloy with high impact resistance, made of the following raw materials in mass percentage: Cu 5%, Ni 2%, V 1.5%, fluorite powder 0.8%, Mg 0.5%, modified carbon fiber 0.7%, nano boron nitride 1%, Ce 0.2%, and the balance Al.

[0020] The modified carbon fiber is prepared through the following steps: Weigh 200g of aluminum nitrate and dissolve it in deionized water, heat it in a water bath to aid dissolution, set the heating temperature to 85°C, and slowly add it dropwise to the aluminum nitrate solution after the aluminum nitrate is completely dissolved Adjust the pH of the solution to 5 with ammonia water, continue heating and stirring to evaporate the liquid to obtain a translucent aluminum sol; add carbon fiber to the prepared aluminum sol and impregnate it for 30 hours, and dry it at 50°C after impregnation; after drying, the impregnated aluminum sol The carbon fiber of the metal oxide gel is put into a muffle furnace and fired for 2 hours to obtain the modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com