Method for treating tungsten-molybdenum organic mixed waste water cleanly and thoroughly and recycling metal and hydrogen gas byproduct synchronously

A technology of mixing wastewater, tungsten and molybdenum, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. and eco-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

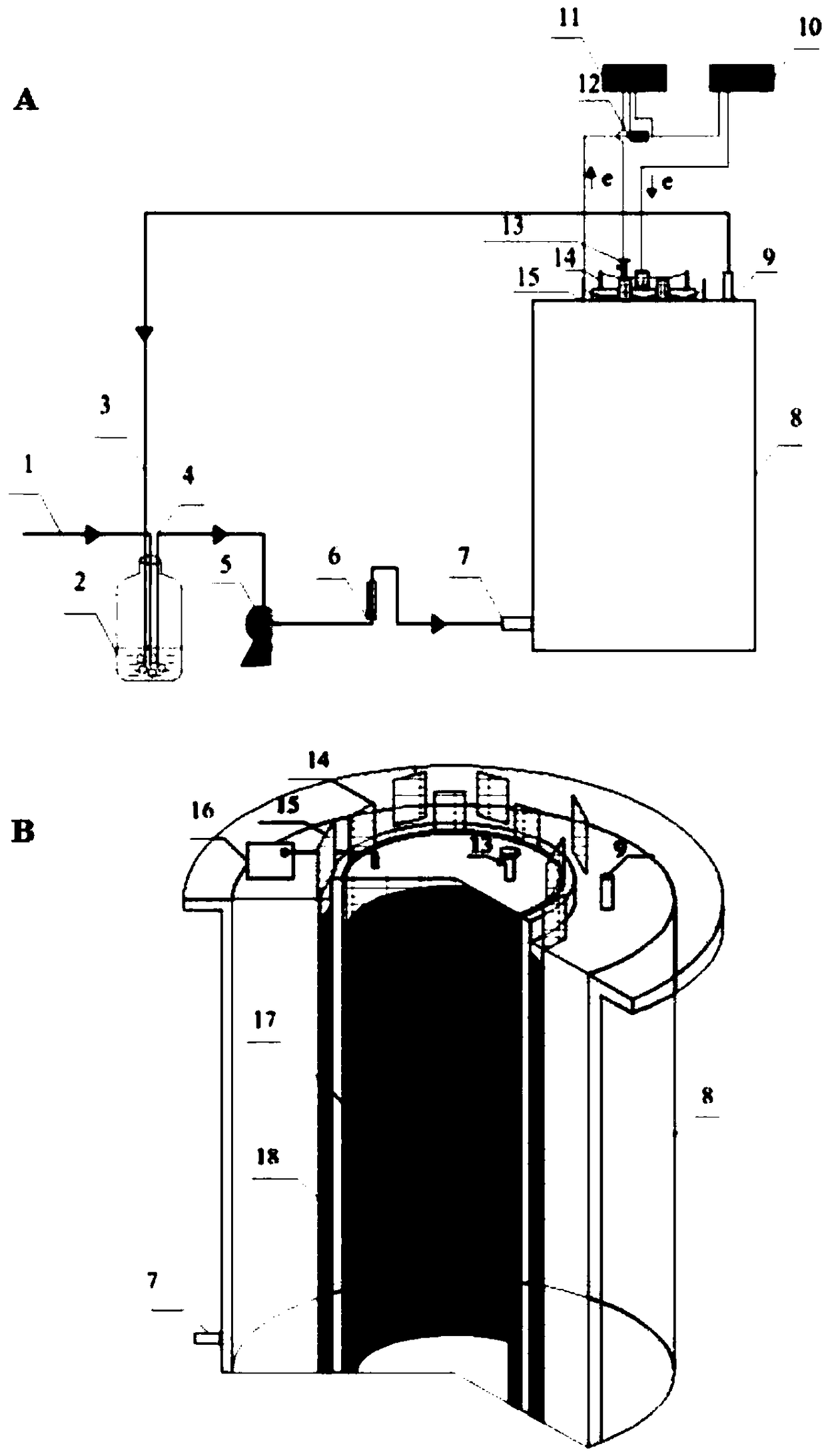

[0031] Step 1: Construct and assemble single-chamber cylindrical MECs, such as figure 1 Shown: The cylindrical MECs are made of plexiglass, wrapped with a layer of tin foil to protect from light. Among them, the outer diameter is 34.0cm, the height is 45.0cm, and the total volume is 40.8L. The reactor is equipped with a headspace with an inner diameter of 18.0cm, a height of 2.0cm, and a volume of 0.5L; a gas collecting bag with a maximum volume of 1.0L is installed in the headspace; a water inlet pipe with an inner diameter of 1.0cm is installed at the bottom of the cylinder, and at the top Equipped with an outlet pipe with an inner diameter of 1.0cm. The anode carbon felt is 69.2cm×40cm×1cm, and the cathode carbon felt is 56.6cm×40cm×1cm. The carbon felt is soaked in 1.0M NaOH and 1.0M HCl solution for 24h to remove surface impurities, and then rinsed with deionized water and soaked until water It is neutral; the size of the anode conductive stainless steel mesh (304, 14 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com