Blending process of cashmere and bamboo fiber blended yarns

A technology of blended yarn and bamboo fiber, which is applied in the field of spinning, can solve the problems of falling down, high price of pure cashmere sweaters, and high price of cashmere, and achieve the effect of luster, elasticity and performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

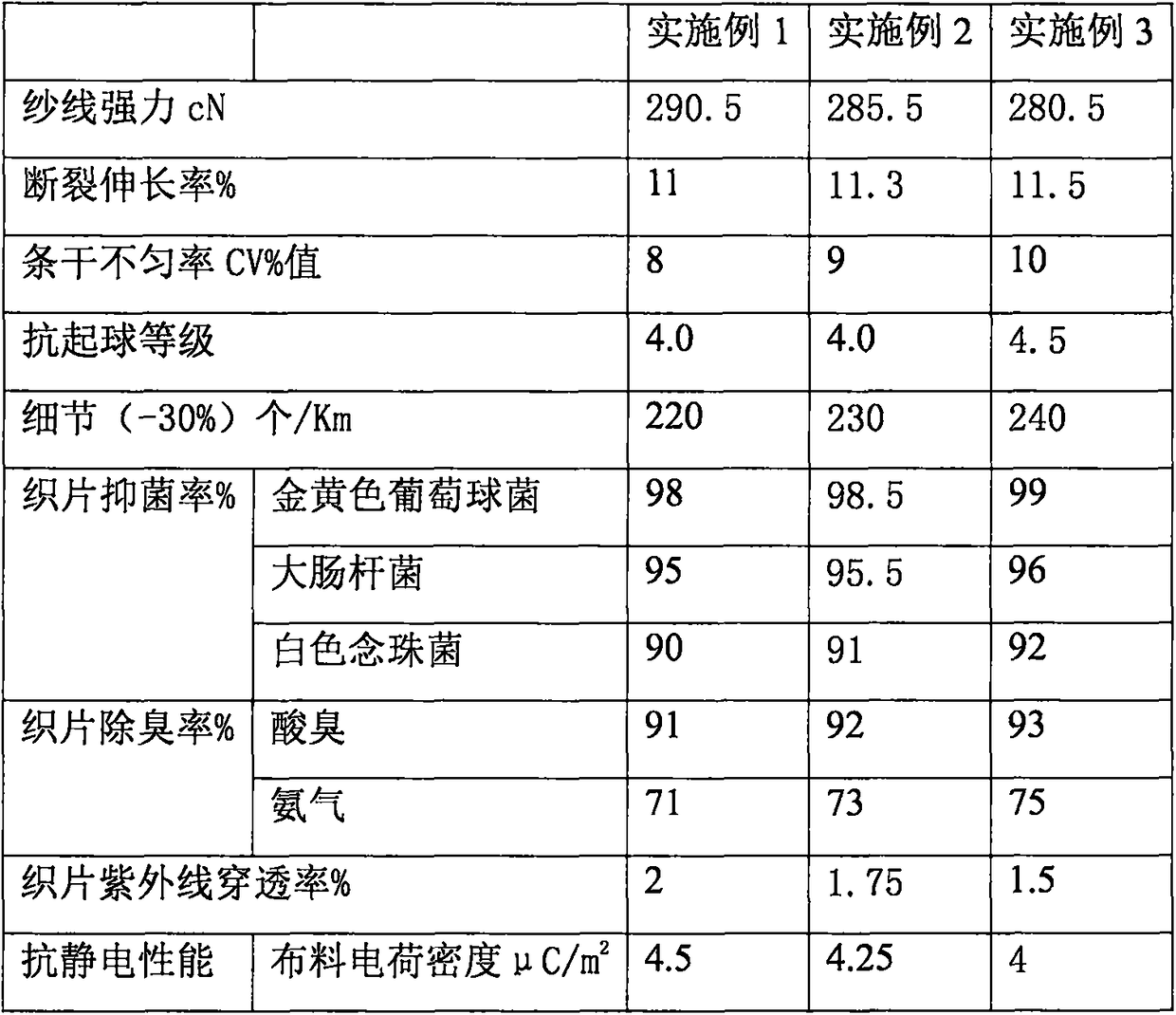

Examples

Embodiment 1

[0039] Step 1, the cashmere is made into a cashmere strip through the processes of blending, carding, blending, blending, combing, needle combing, stripping, re-combing, scalp stitching, and second stitching according to the raw materials;

[0040] The cashmere raw material is selected from cashmere with an average length of 35mm, a fineness of 15 μm, and a fineness dispersion of 20%;

[0041] The wool blending process adopts a B262 wool blending machine; the cashmere is mixed with 3.5% hair oil and water in mass concentration, and after mixing evenly, the wool is stuffed for 20 hours. When kneading cashmere, the mixture should be fully loosened and mixed evenly to ensure that the oil and water are evenly distributed and the moisture regain is stable on the machine;

[0042] Described carding adopts Octier carding machine;

[0043] The combing and compound combing adopt PB29 combing machine;

[0044] The needle comb adopts a GN5 needle card machine to carry out 4 needle comb...

Embodiment 2

[0056] Step 1, the cashmere is made into a cashmere strip through the processes of blending, carding, blending, blending, combing, needle combing, stripping, re-combing, scalp stitching, and second stitching according to the raw materials;

[0057] The cashmere raw material is selected from cashmere with an average length of 38mm, a fineness of 15.5 μm, and a fineness dispersion of 22%;

[0058] The wool blending process adopts a B262 wool blending machine; the cashmere is mixed with 3.5% hair oil and water in mass concentration, and the wool is stuffed for 23 hours after mixing evenly. When kneading cashmere, the mixture should be fully loosened and mixed evenly to ensure that the oil and water are evenly distributed and the moisture regain is stable on the machine;

[0059] Described carding adopts Octier carding machine;

[0060] The combing and compound combing adopt PB29 combing machine;

[0061] The needle comb adopts a GN5 needle card machine to carry out 4 needle com...

Embodiment 3

[0073] Step 1, the cashmere is made into a cashmere strip through the processes of blending, carding, blending, blending, combing, needle combing, stripping, re-combing, scalp stitching, and second stitching according to the raw materials;

[0074] The cashmere raw material is selected from cashmere with an average length of 40mm, a fineness of 16 μm, and a fineness dispersion of 23%;

[0075] The wool blending process adopts a B262 wool blending machine; the cashmere is mixed with 3.5% hair oil and water, and after mixing evenly, the wool is stuffed for 25 hours. When kneading cashmere, the mixture should be fully loosened and mixed evenly to ensure that the oil and water are evenly distributed and the moisture regain is stable on the machine;

[0076] Described carding adopts Octier carding machine;

[0077] The combing and compound combing adopt PB29 combing machine;

[0078] The needle comb adopts a GN5 needle card machine to carry out 4 needle combs;

[0079] Step 2, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com