Basement bottom plate water leakage repairing system

A basement floor and water leakage technology, applied in the repair of infrastructure, protection devices, construction, etc., can solve problems such as waterproof failure, concrete floor, side wall cracking, concrete honeycomb, etc., to increase service life and reduce safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

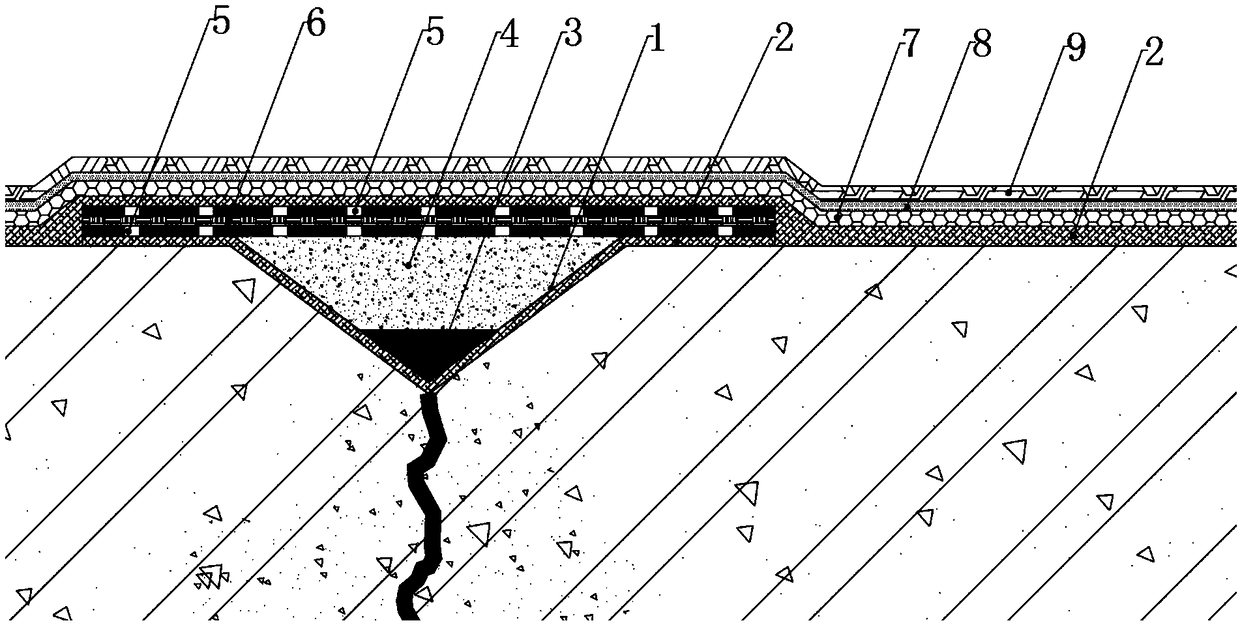

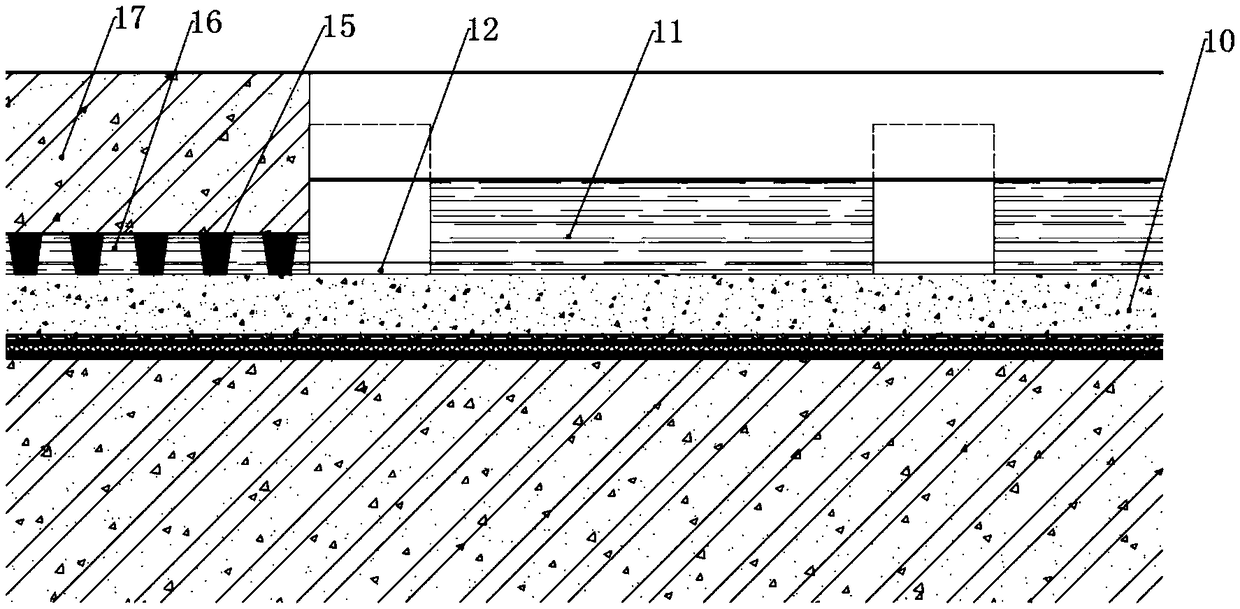

[0052] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased from the market.

[0053] The following is a specific description of the basement floor leakage repair system of the embodiment of the present invention.

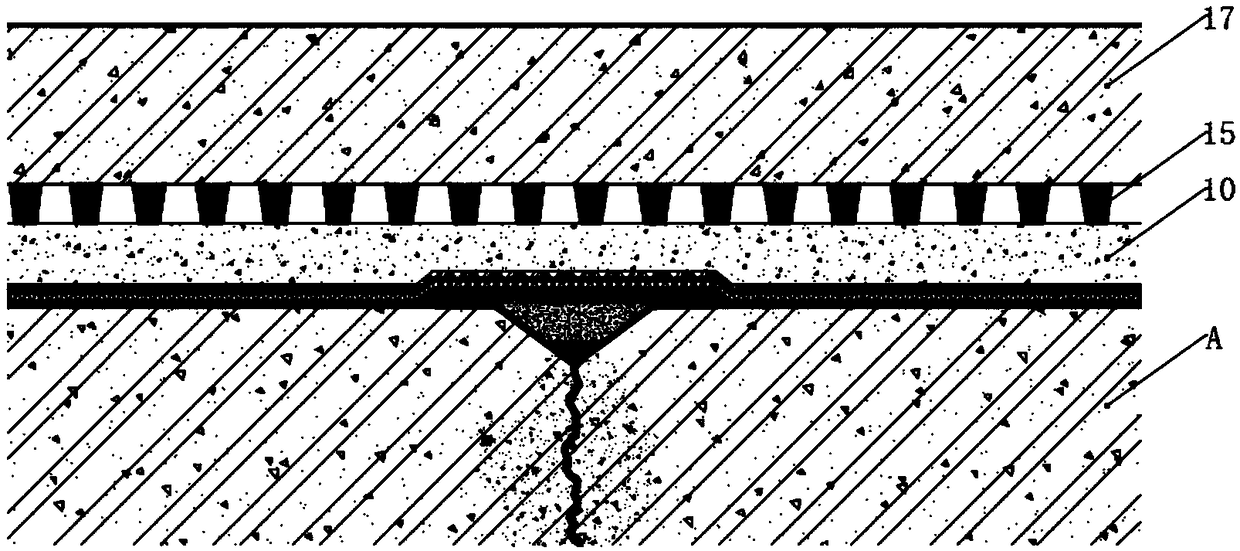

[0054] refer to Figure 1-Figure 4 As shown, the embodiment of the present invention provides a basement floor leakage water repair system, and the construction steps of the repair system include:

[0055] S1, knock out the crushed stone concrete cushion of the basement floor to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com