Method for inducing crystallization orientation of perovskite thin film and prepared solar cell

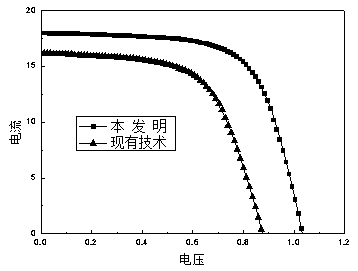

A technology of solar cells and crystal orientation, applied in the field of solar cells, can solve the problems that the grain distribution of perovskite thin films is not particularly uniform, which affects the photoelectric conversion efficiency of devices, and achieves photoelectric conversion efficiency improvement, reduction of density defects, and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

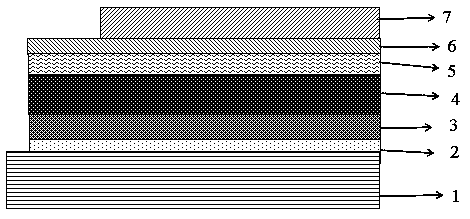

[0023] Embodiment one: use lead iodide (PbI 2 ) and methyl ammonium chloride (MACl) induced perovskite crystal orientation films to prepare reverse planar perovskite solar cell devices.

[0024] Step 1: The glass substrate engraved with ITO electrodes was ultrasonically cleaned in deionized water, acetone, and ethanol for 14 minutes each, and after thorough cleaning, it was placed in an ozone plasma processor to clean the surface for 5 minutes.

[0025] Step 2: Preparation of the hole transport layer: the prepared NiOx solution was spin-coated on the ITO glass at a speed of 4000 rpm, and then annealed at 130°C for 10 min.

[0026] Step 3: Preparation of precursor solution: lead iodide (PbI 2 ) and methylammonium chloride (MACl) are dissolved in a mixed solvent of dimethylamide (DMF) and dimethyl sulfoxide (DMSO) with a volume ratio of 1:1 at a molar ratio of 1:1, and the precursor solution The final molarity was 1.18 mol / L, and stirred at room temperature for 2 h.

[0027] ...

Embodiment 2

[0030] Embodiment two: use lead iodide (PbI 2 ) and methylammonium iodide (MAI) to prepare reverse planar perovskite solar cell devices.

[0031] The difference from the preparation steps in Example 1 is Step 3, and all other steps and methods are exactly the same as in Example 1.

[0032] Step 3 of this embodiment: preparation of perovskite film precursor solution: lead iodide (PbI 2 ) and methylammonium iodide (MAI) were dissolved in dimethylamide (DMF) and dimethyl sulfoxide (DMSO) solvents with a volume ratio of 1:1 at a molar ratio of 1:1, and the final molar concentration of the precursor solution 1.18 mol / L, and stirred at room temperature for 2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com