Dimethylcurcumin solid dispersoid as well as preparation method and application thereof

A technology of dimethyl curcumin and solid dispersion, which is applied in the field of dimethyl curcumin solid dispersion and its preparation, and can solve the problems of poor water solubility of dimethyl curcumin, limitation of preparation development and utilization, and slow oral release speed, etc. , to achieve the effect of low price, high bioavailability and high dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

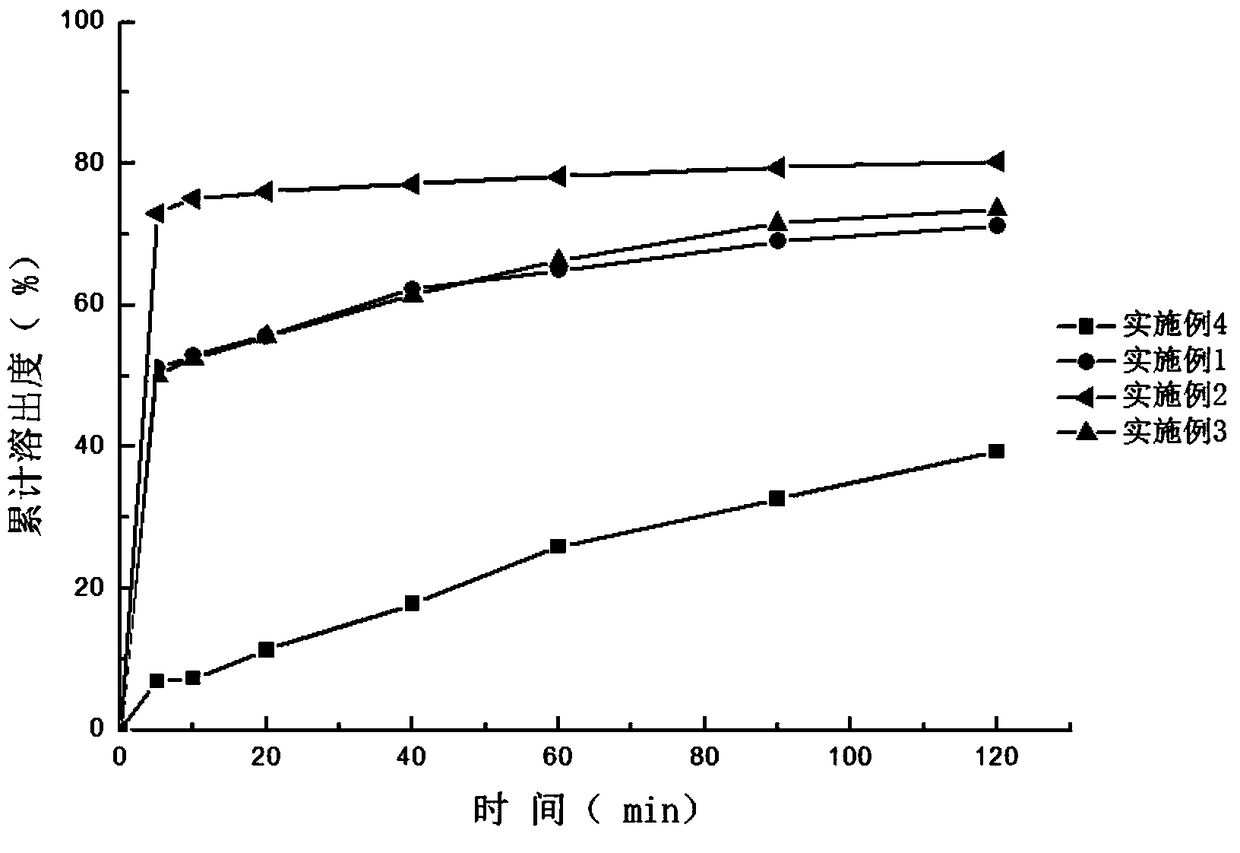

Embodiment 1

[0041] A solid dispersion of dimethyl curcumin, consisting of dimethyl curcumin and PEG4000, using a melting method, heating 2 g of PEG4000 in a water bath at 60 to 80 ° C to melt, and under constant stirring, 1 g of dimethyl curcumin Add the ingredients in batches, continue to stir for 30 minutes, pour the molten material onto a glass container and spread it into a thin layer, cool it quickly, dry it in a desiccator for 24 hours, crush it, and pass it through a 100-mesh sieve to obtain dimethyl curcumin / PEG4000 solid Dispersion, in vitro dissolution test results show that: 5min dissolution rate is 51.07%, 2h dissolution rate is 71.15%, it can be seen that the solid dispersion prepared with PEG4000 as carrier can effectively improve the dissolution behavior of dimethyl curcumin.

Embodiment 2

[0043] A solid dispersion of dimethyl curcumin, consisting of dimethyl curcumin and PEG4000, using a melting method, heating 10 g of PEG4000 in a water bath at 60 to 80 ° C to melt, and under constant stirring, 1 g of dimethyl curcumin Add the ingredients in batches, continue to stir for 30 minutes, pour the molten material onto a glass container and spread it into a thin layer, cool it quickly, dry it in a desiccator for 24 hours, crush it, and pass it through a 100-mesh sieve to obtain dimethyl curcumin / PEG4000 solid Dispersion, in vitro dissolution test results show that: 5min dissolution rate is 50.08%, 2h dissolution rate is 73.51%, it can be seen that the solid dispersion prepared with PEG4000 as carrier can effectively improve the dissolution behavior of dimethyl curcumin.

Embodiment 3

[0045]A solid dispersion of dimethyl curcumin, which is composed of dimethyl curcumin and PEG4000, using a melting method, heating 4 g of PEG4000 in a water bath at 60 to 80 ° C to melt, and under constant stirring, 1 g of dimethyl curcumin Add the ingredients in batches, continue to stir for 30 minutes, pour the molten material onto a glass container and spread it into a thin layer, cool it quickly, dry it in a desiccator for 24 hours, crush it, and pass it through a 100-mesh sieve to obtain dimethyl curcumin / PEG4000 solid Dispersion, in vitro dissolution test results show that: 5min dissolution rate is 51.07%, 2h dissolution rate is 71.15%, it can be seen that the solid dispersion prepared with PEG4000 as carrier can effectively improve the dissolution behavior of dimethyl curcumin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com