Method and system for online scale inhibition, biocidal and scale removal of continuous casting crystallizer

A continuous casting mold, biocide and descaling technology, applied in the field of metallurgy, can solve the problem of uneven heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention is a method for on-line scale inhibition, killing and descaling of continuous casting crystallizers, which comprises the following steps:

[0025] Step a, send high-concentration ozone water into the pipeline connected to the water inlet end of the continuous casting crystallizer and dilute it with the water in the pipeline, then enter the continuous casting crystallizer with the diluted ozone water along the water flow direction in the pipeline, pass The diluted ozone water treats the fouling layer on the surface of the continuous casting crystallizer; in this step, the high-concentration ozone water is a dilution of the conventional continuous casting crystallizer that needs to be treated and the scaling layer in the continuous casting crystallizer. As far as the concentration of ozone water is concerned, it is generally based on 10mg / l, and its concentration can be adjusted according to actual conditions, such as the size of the continuous castin...

Embodiment 2

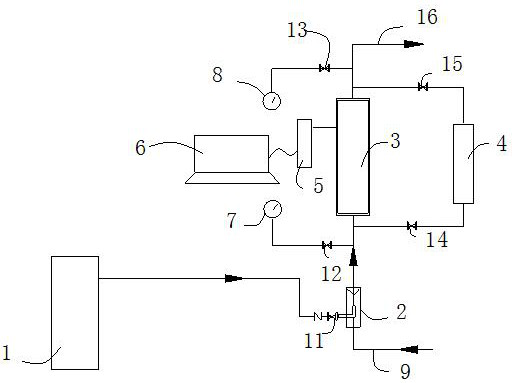

[0030] Such as figure 1 As shown, the present invention is a continuous casting crystallizer on-line scale inhibition, killing and scale removal system, which includes a continuous casting crystallizer 3, a main water inlet pipeline 9, a main water outlet pipeline 16, an ozone dosing device 1, and a pipeline mixer 2. The first ozone concentration detector 7 and the second ozone concentration detector 8; the water inlet end and the water outlet end of the continuous casting crystallizer 3 are respectively connected with the main water inlet pipe 9 and the main water outlet pipe 16 through pipelines; The pipeline mixer 2 is arranged on the pipeline connected with the water inlet end of the continuous casting crystallizer 3; the ozone dosing device 1 is connected with the pipeline mixer 2 through the pipeline; the first ozone concentration detector 7 is arranged on the continuous casting crystallizer On the pipeline between the water inlet of the device 3 and the pipeline mixer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com