Preparation method and application of ethylene sulfate

A technology of vinyl sulfate and vinyl sulfite, which is applied in the field of preparation of vinyl sulfate, can solve the problems of troublesome post-processing, low oxidation efficiency, and low product purity, and achieve simple post-processing, easy operation, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

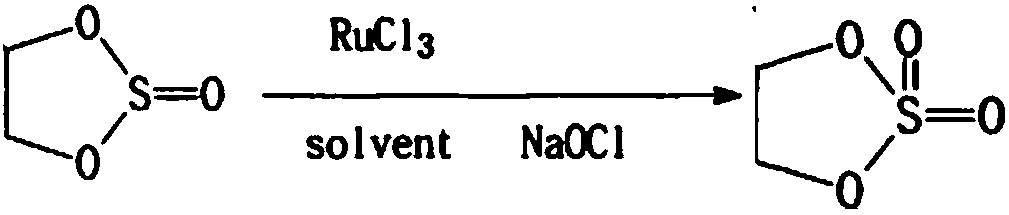

Method used

Image

Examples

Embodiment 1

[0018] Get 108.2g (1mol) vinyl sulfite, 200ml distilled water and 0.2g powdered catalyst (by mass ratio, CuO:NiO:Al 2 o 3 =1:0.85:1.3), stir slowly and evenly, control the temperature at 5°C, pass ozone 0.05L / min (ozone concentration is 20mL / L), and react for 45 minutes. After the reaction was finished, the mixture was left standing to separate layers, and the organic layer was taken. The organic layer was washed twice with distilled water and dried to obtain vinyl sulfate with a yield of 94.53%. The product was analyzed by liquid chromatography, and the results showed that the content of vinyl sulfate was 94.36%, and the content of vinyl sulfite was 5.52%.

Embodiment 2

[0020] Get 216.3g (2mol) vinyl sulfite, 200 milliliters of distilled water and 0.4g granular catalyst (by mass ratio, Cu:NiO:MnO 2 =1:1.2:0.8), stir slowly and evenly, control the temperature at 5°C, pass ozone 0.05L / min (ozone concentration is 20mL / L), and react for 45min. After the reaction was completed, the layers were left to stand, and the organic layer was taken. The organic layer was washed twice with distilled water and dried to obtain vinyl sulfate with a yield of 95.84%. The product was analyzed by liquid chromatography, and the results showed that the content of vinyl sulfate was 95.63%, and the content of vinyl sulfite was 4.28%.

Embodiment 3

[0022] Get 2.161kg (2mol) vinyl sulfite, 2L distilled water and 4g powdered catalyst (by mass ratio, Fe:MnO:Al 2 o 3 =1:1.1:0.9), stir slowly and evenly, control the temperature at 5°C, pass through ozone 0.05L / min (ozone concentration is 20mL / L), react for 60min, after the reaction is over, let it stand for stratification, and take the organic layer , the organic layer was washed twice with distilled water and dried to obtain vinyl sulfate with a yield of 95.17%. The product was analyzed by liquid chromatography, and the results showed that the vinyl sulfate content was 95.13%, and the vinyl sulfite content was 4.68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com