A kind of nano-sic reinforced aluminum matrix composite material and preparation method thereof

A technology for strengthening aluminum-based and composite materials. It is applied in the field of aluminum-based composite materials. It can solve the problems of weakening the strengthening effect of aluminum alloys, restricting the application of nano-SiC particles, and agglomerating nanoparticles, and achieves the effect of improving hardness and high-temperature mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

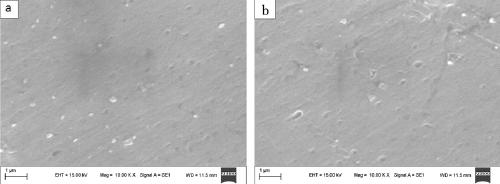

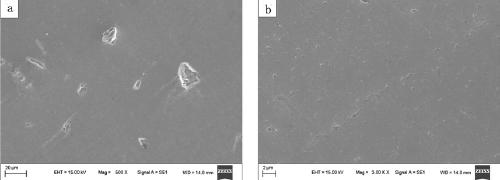

Image

Examples

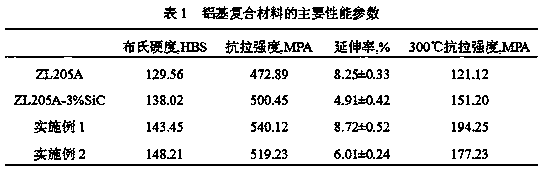

Embodiment 1

[0030] Add nano-SiC particles into a quartz crucible, roast at 1200°C for 2 hours to oxidize the surface, then place in 5% HF solution, pickle at 40°C for 25 minutes, and clean the acid solution and pickling on the nano-SiC particles with distilled water The product was placed in a saturated NaOH solution at 100° C. for 2 h, and rinsed with distilled water to obtain pretreated nano-SiC.

[0031] The pretreated nano-SiC and graphene were mixed at a mass ratio of 20:1, added to a 10% KH560 solution, ultrasonically treated in a water bath for 30 min, and evaporated to dryness by gas atomization to prepare a graphene-coated nano-SiC prefabricated powder.

[0032] Take cast aluminum ZL205A and heat it to 710°C to obtain an aluminum alloy melt. Cool down the aluminum alloy melt to 660°C, inject high-purity argon and keep it warm for 5 minutes. Stir the aluminum alloy melt at a speed of 400rmp, and under ultrasonic treatment, slowly add prefabricated powder accounting for 3% of the ...

Embodiment 2

[0035] Add nano-SiC particles into a quartz crucible, roast at 1150°C for 3 hours to oxidize the surface, then place in 5% HF solution, pickle at 40°C for 25 minutes, and clean the acid solution and pickling on the nano-SiC particles with distilled water The product was placed in a saturated NaOH solution at 80° C. for 3 h, and rinsed with distilled water to obtain pretreated nano-SiC.

[0036] The pretreated nano-SiC and graphene were mixed at a mass ratio of 15:1, added to a 10% KH560 solution, ultrasonically treated in a water bath for 50 min, and evaporated to dryness by gas atomization to prepare a graphene-coated nano-SiC prefabricated powder.

[0037] Take cast aluminum ZL205A and heat it to 700°C to obtain an aluminum alloy melt. Cool down the aluminum alloy melt to 640°C, inject high-purity argon gas and keep it warm for 5 minutes. Stir the aluminum alloy melt at a speed of 600rmp, and under ultrasonic treatment, slowly add prefabricated powder accounting for 5% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com