A conformal micro-constrained rigid support device and heat treatment method for deformation control of thin-walled aluminum alloy castings

An aluminum alloy casting and rigid support technology is applied in the field of aluminum alloy deformation control, which can solve the problems of limited effect of component deformation control, waste of materials, labor or time, and overall deformation of castings. The effect of high yield and deformation tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

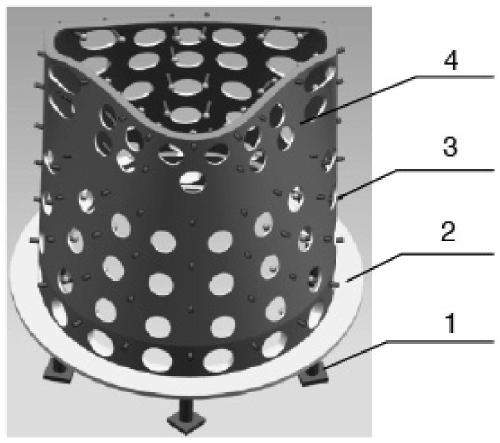

[0027] Example: such as figure 1 As shown, a conformal micro-constrained rigid support device for deformation control of thin-walled aluminum alloy castings includes a bottom tray 2 and a conformal skeleton 4 arranged on the bottom tray. Shaped, threaded holes are provided on the conformal framework, and bolts 3 are installed in the threaded holes from inside to outside, the bolts correspond to the intersection points of longitudinal and ring ribs in the inner cavity of the casting, and on the conformal framework A plurality of openings 5 are provided.

[0028] In addition, as another implementation of this embodiment, a support base 1 is further provided at the bottom of the bottom tray.

[0029] Wherein, the unilateral spacing between the conformal skeleton and the inner cavity of the casting is 15 to 20mm, and the unilateral distance refers to the distance from the inner cavity wall of the casting to the outer wall of the conformal framework after the casting is sleeved ...

Embodiment 2

[0055] Example 2: Using the device and method provided in Example 1, a large complex thin-walled aluminum alloy casting is used as the application object. 6 windows of 220mm, 2 windows of 450×350mm, typical cabin casting structure, material ZL205A.

[0056] The heat treatment deformation control operation steps of the conformal micro-constrained rigid support device are carried out as follows:

[0057] (1) Before heat treatment, hoist the casting into the conformal micro-constrained rigid support device, align the casting with the center of the device through the limit block, and then adjust the position and strength of the support bolt with a manual wrench in the inner cavity of the device, layer by layer. Tighten each support bolt with controlled force.

[0058] (2) Hoist the conformal micro-constrained rigid support device equipped with castings into a heat treatment furnace with a temperature control accuracy within ±5°C for solid solution treatment, first heat it to 320±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com