Coating failure monitoring probe and rapid field coating failure monitoring method

A failure monitoring and coating technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inconvenient on-site inspection of vehicle or aircraft coatings, and achieve the effects of simple structure, high response sensitivity and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

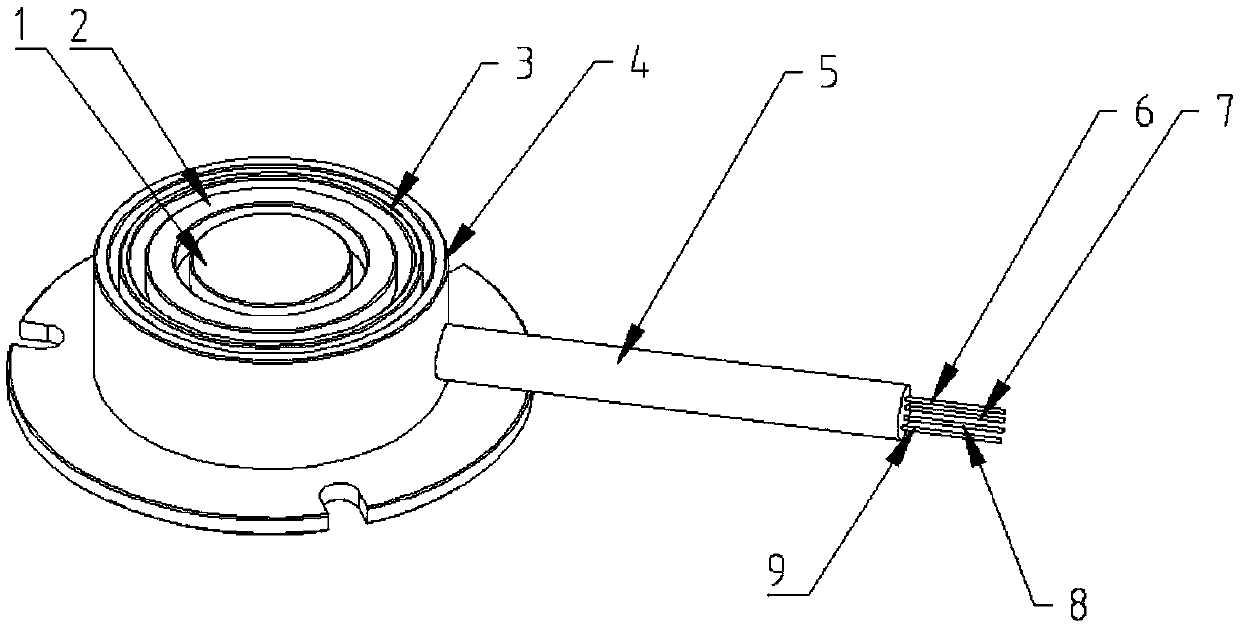

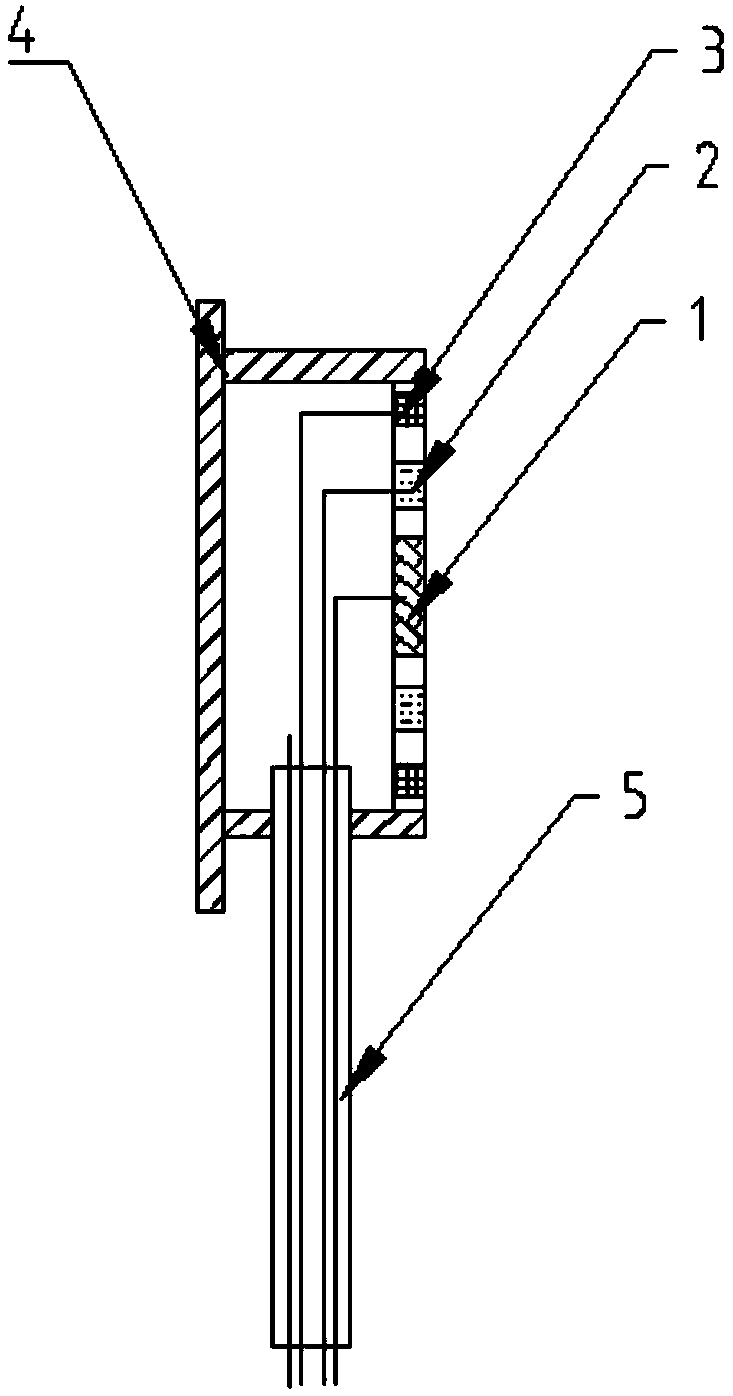

[0063] figure 1 It is a specific structure of a coating failure monitoring probe used in combination with the principle of electrochemical AC impedance, combined with figure 1 with figure 2 , the coating failure monitoring probe comprises a probe cavity 4, a probe inner core positioned in the probe cavity, a base plate positioned at the bottom of the probe cavity and an outer guide wire 5, the upper end of the cavity 4 is open, and the base plate is preferably a stainless steel base plate. The outer guide wire 5 is connected to the inner core of the probe and extends out of the probe cavity 4 .

[0064] Cavity 4 is made of ABS resin shell, and this shell is cylindrical tubular structure, and its longitudinal middle position is the inner core of probe. The inner core of the probe adopts a three-electrode system defined in electrochemistry, including a working electrode 1, a reference electrode 2 and an auxiliary electrode 3. The three electrodes are all made of 7075 aluminum...

Embodiment 2

[0068] The four wires of the monitoring probe in this embodiment are connected on the AC impedance tester to form a fast monitoring sensor for the failure of the acoustic coating. The sensor uses AC impedance technology to monitor the failure degree of the coating on site. The specific method is:

[0069] (1) Obtain the initial impedance modulus and initial phase angle: monitor the initial moment, apply the same new coating as the metal coating to be tested on the working surface of the coating failure monitoring probe, and apply a fixed frequency to the AC impedance tester The 10-30mV sine wave signal forms a current loop on the surface of the probe, and is calculated by IV conversion circuit and phase correlation method to obtain the initial impedance modulus and initial phase angle at the initial moment at a certain frequency;

[0070] (2) Obtain the measured impedance modulus and measured phase angle at a certain measurement moment: at a certain measurement moment, the AC ...

Embodiment 3

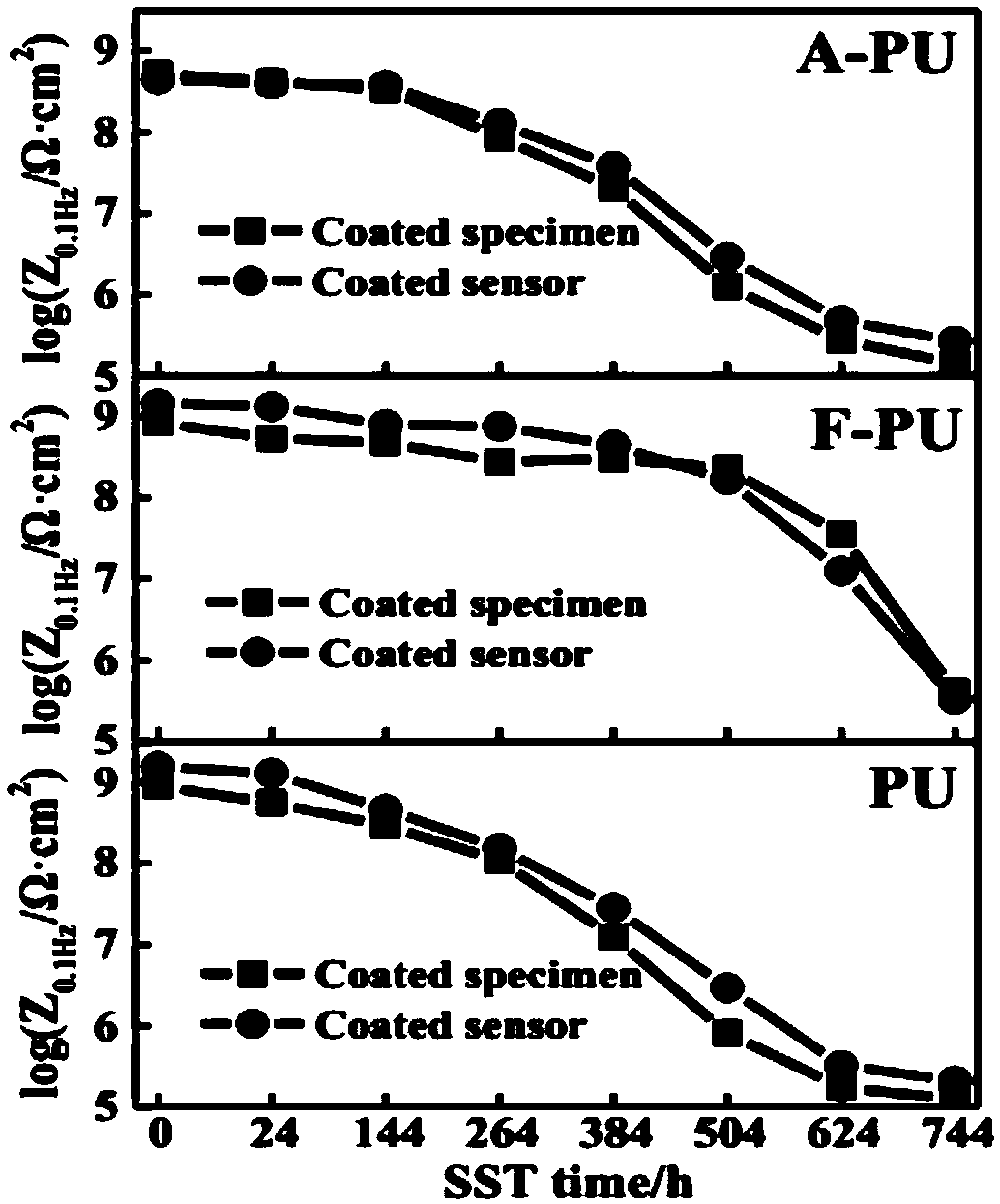

[0074] Three different portable coating probes (A-PU, F-PU, PU) were used for the accelerated salt spray test. The neutral salt spray test was carried out according to the ISO7253 standard to accelerate coating aging, and all samples were exposed to 5% NaCl (pH=7) and carried out in a salt spray chamber at a temperature of 35±2°C. The salt spray test was set to 60 minutes of spraying, intermittent spraying and 60 minutes of drying interval to simulate the drying and wetting process in the alternate spraying marine environment. At the same time, the electrochemical impedance of the coating under different aging times was tested in real time. Impedance test parameters: AC amplitude 20mV, scanning frequency range 100kHz ~ 0.01Hz, logarithmic scanning, 10 points / 10 times frequency.

[0075] The test results show that when the salt spray of three different portable coating probes (A-PU, F-PU, PU) is accelerated, the diameter length of the capacitive reactance arc decreases and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com