Light trapping structure glue and smooth textured crystalline silicon composite battery and processing method thereof

A technology of crystalline silicon cells and light-trapping structures, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as limiting the photoelectric conversion efficiency of crystalline silicon cells, weakening the photovoltaic effect of crystalline silicon cells, and inconsistent high-temperature diffusion of crystalline silicon. To achieve the effect of enhancing the photovoltaic effect, improving the photovoltaic effect, and facilitating the absorption of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below with reference to the accompanying drawings and examples; however, a photovoltaic module of the present invention laminated with a light-trapping structural adhesive and a smooth textured crystalline silicon cell and its processing method are not limited to the examples.

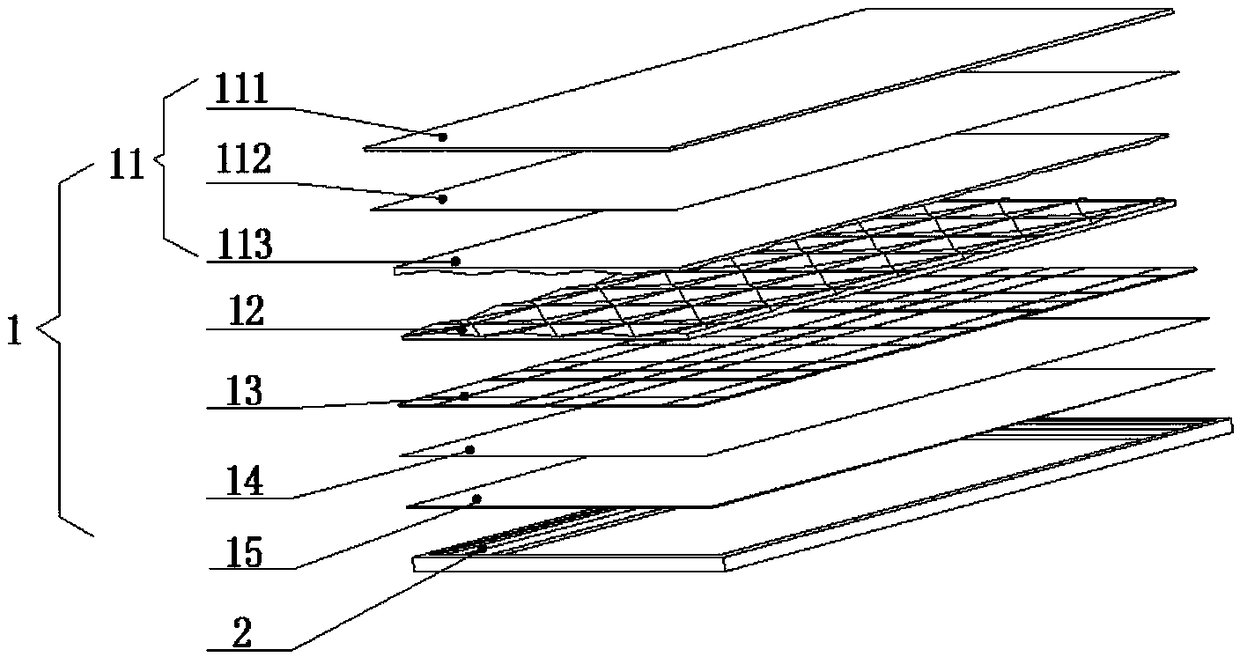

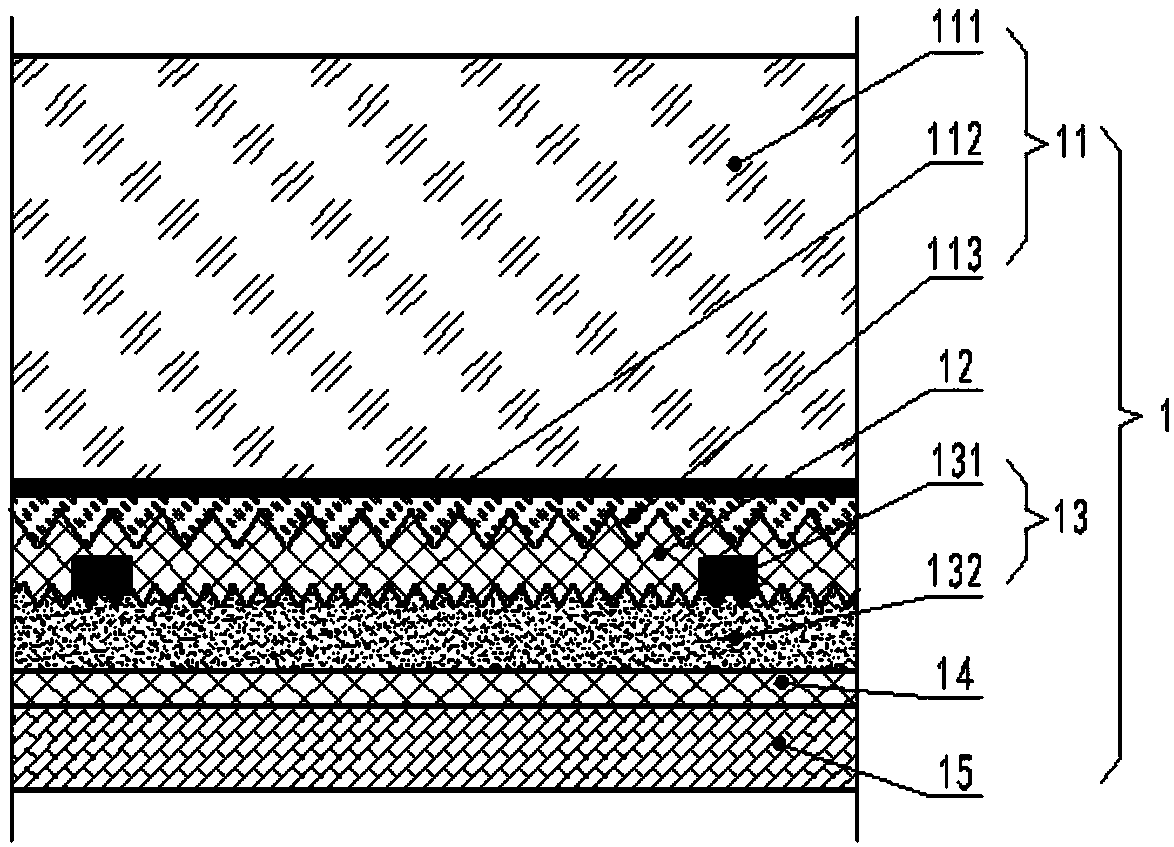

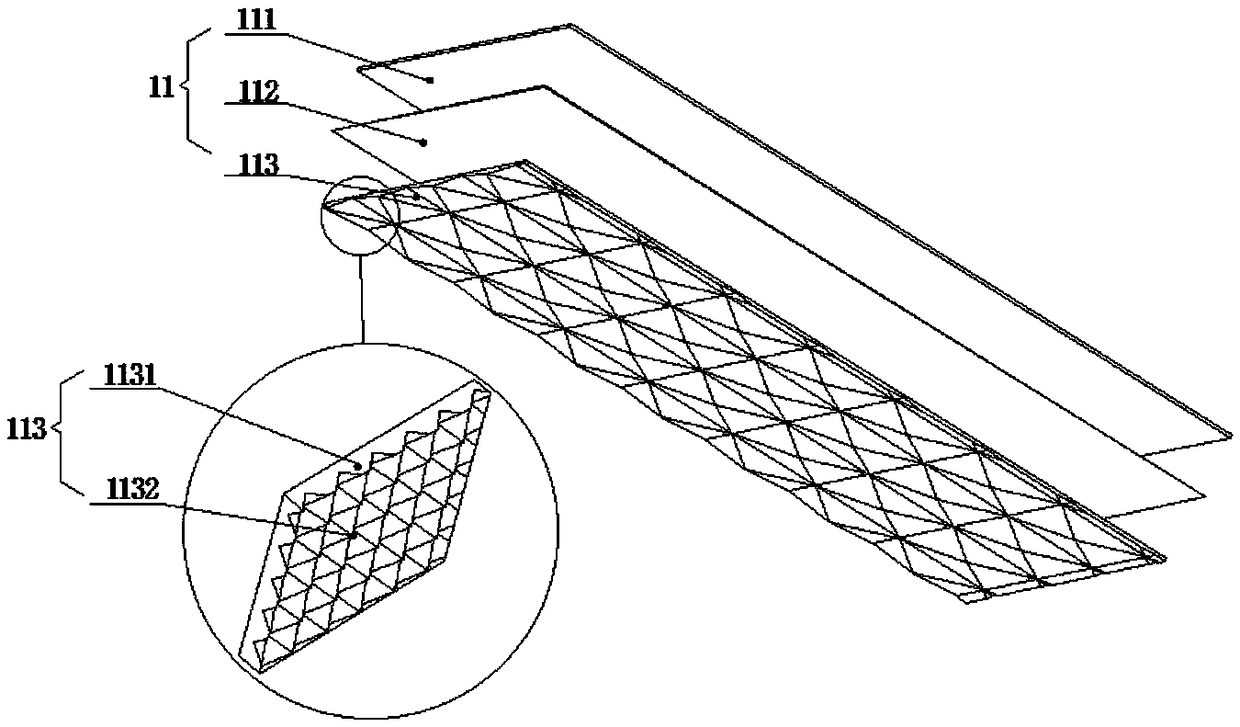

[0033] Examples, see Figure 1-Figure 5 As shown, a photovoltaic module laminated with a light-trapping structural adhesive and a smooth textured crystalline silicon cell of the present invention includes a photovoltaic cell panel 1 and an aluminum alloy frame 2, and the photovoltaic cell panel includes a high-transparency light-trapping master template 11, a trapping The optical structure adhesive layer 12, the smooth suede crystalline silicon battery 13, the plane structural adhesive layer 14, and the TPT plastic 15 are stacked together from top to bottom in sequence, and the aluminum alloy frame 2 is fixed around the photovoltaic cell p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com