Composite ceramic porous lithium battery diaphragm, preparation method and application of composite ceramic porous lithium battery diaphragm

A composite ceramic and diaphragm technology, applied in lithium batteries, circuits, electrical components, etc., can solve the problems of reduced stability of lithium battery diaphragms, short circuit of positive and negative electrodes of lithium batteries, uneven or unequal coating, and reduce battery short circuit phenomenon. , The effect of improving production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

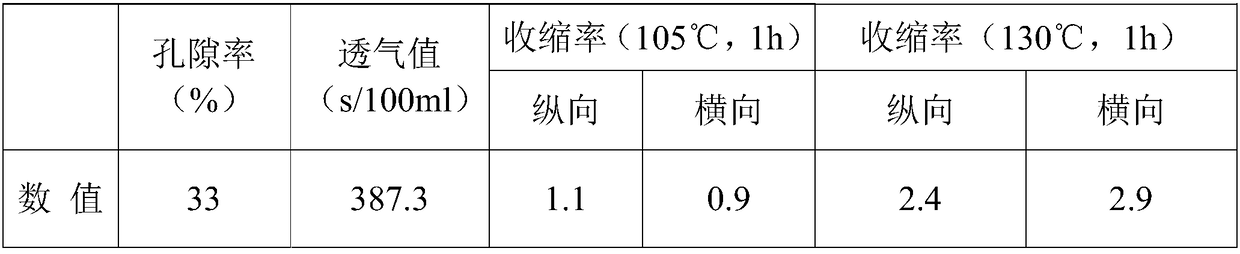

Embodiment 1

[0021] (1) Weigh and mix the raw materials in the following weight ratio: 30% polyethylene with an average molecular weight of 1.2 million, 55% kerosene, octadecyl-3-(3,5-di-tert-butyl-4-hydroxybenzene Base) 8% acrylate, 7% ceramic particles with a particle size of 10nm.

[0022] (2) Pass the mixed raw materials through a twin-screw extruder at 180°C to obtain a high-temperature melt. The high-temperature melt is accurately metered by a melt pump and then sent to the die, and the high-temperature melt fed into the die passes through the slit of the die The high-temperature melt flowing out from the slit of the die passes through the chilled roll to obtain extruded cast pieces;

[0023] (3) extruding the cast sheet and entering the bidirectional synchronous stretching machine to obtain an oily film with a longitudinal ratio of 4 times and a transverse ratio of 5 times;

[0024] (4) After fully immersing the oil-containing diaphragm in dichloromethane for 15 minutes, remove the...

Embodiment 2

[0029] According to the process of Example 1, the raw materials and their proportions are changed, and other process conditions remain unchanged. The specific raw materials and proportions are as follows: 25% of polyethylene with an average molecular weight of 1.3 million, 60% of paraffin oil, pentaerythritol-tetra-[3- (3,5-di-tert-butyl-4-hydroxyphenyl) acrylate] 8%, ceramic particles with a particle size of 20nm 7%.

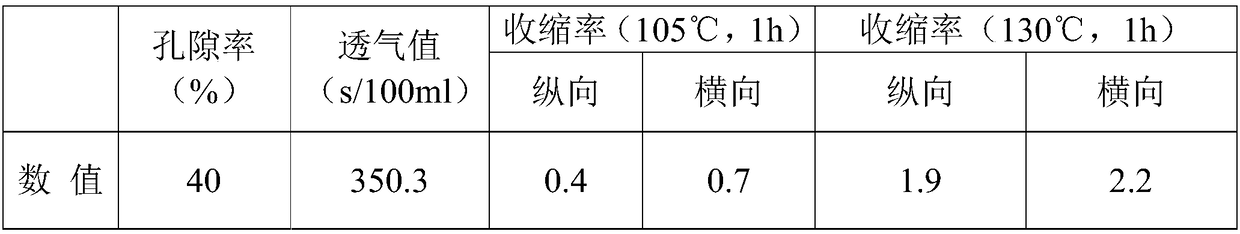

[0030] After testing, the pore diameter of the composite ceramic porous lithium battery separator is 110nm. The porosity and air permeability of the separator material of the present invention were measured, and the shrinkage rate was tested after being heated at 105° C. and 130° C. for 1 hour respectively. The results are shown in Table 2.

[0031] Table 2

[0032]

Embodiment 3

[0034] According to the process of Example 1, the raw materials and their proportions are changed, and other process conditions remain unchanged. The specific raw materials and proportions are as follows: 25% polyethylene with an average molecular weight of 1.3 million, 60% white oil, 2,6-di-tert-butyl Base-4-methylphenol 8%, ceramic particles with a particle size of 30nm 7%.

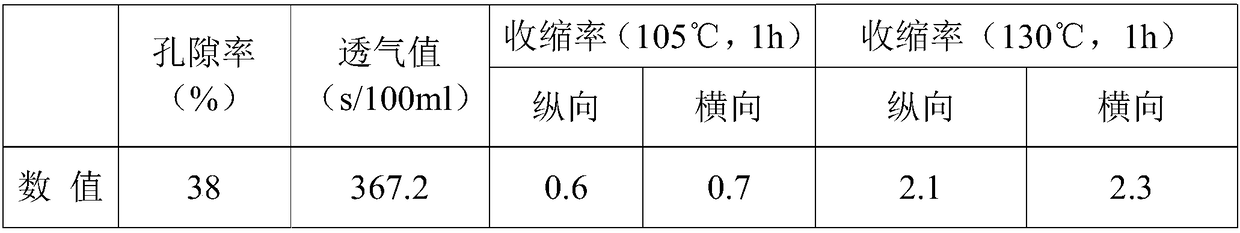

[0035] After testing, the pore diameter of the composite ceramic porous lithium battery diaphragm is 130nm. The porosity and air permeability of the separator material of the present invention were measured, and their shrinkage rates were tested after being heated at 105° C. and 130° C. for 1 hour respectively. The results are shown in Table 3.

[0036] table 3

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com