Preparation method of atomic crystal boron-doped carbon material

A carbon material and boron doping technology, applied in chemical instruments and methods, nano-carbon, carbon compounds, etc., can solve problems such as carbon structural defects, inability to ensure uniform distribution of boron atoms, limited introduction methods, etc., to achieve less defects, boron The effect of adjustable content and high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

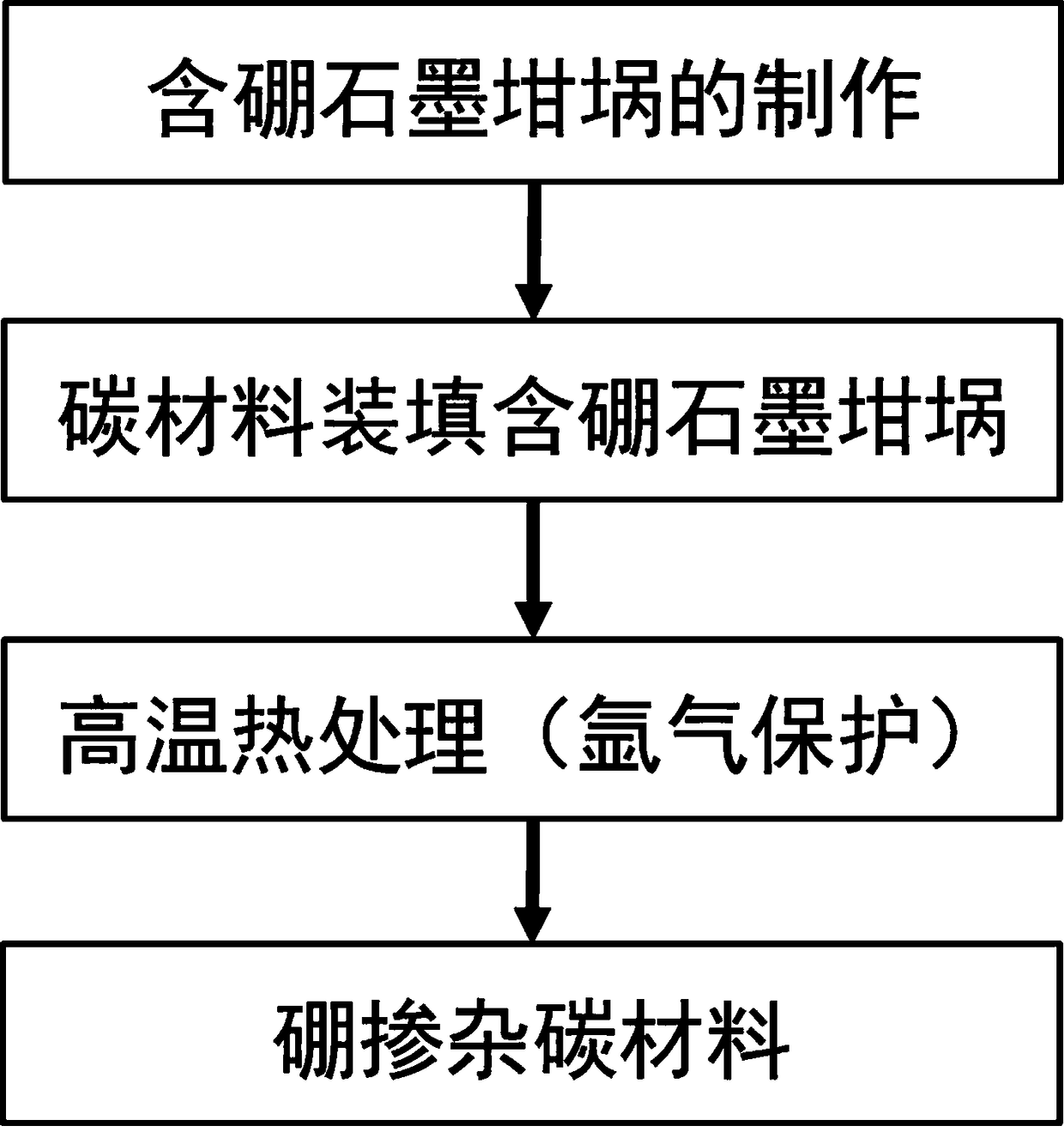

[0027] A method for preparing an atomic crystal boron-doped carbon material, comprising the steps of:

[0028] (1) Boron is introduced into the graphite crucible: first, 25% amorphous boron powder, 35% coal-based pitch, and 40% coke powder are kneaded, and the kneading temperature is 150 ° C. The kneaded material is cooled to room temperature, and then crushed to 90 μm , and then placed in the mold for steel molding, and then carbonized and pre-graphitized, the highest temperature is lower than 1800°C. Finally, the boron-containing graphite block is processed into a screw-sealable crucible;

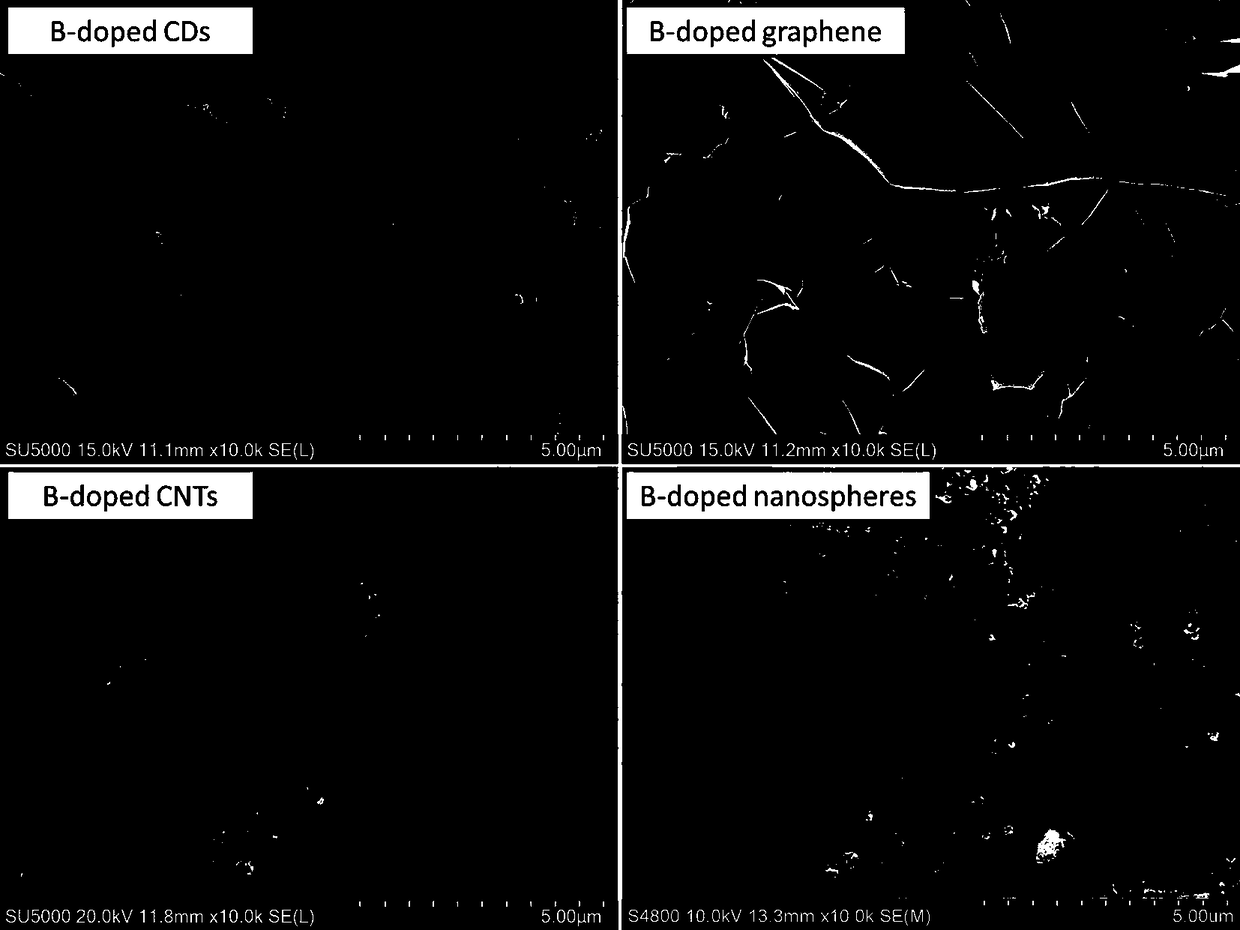

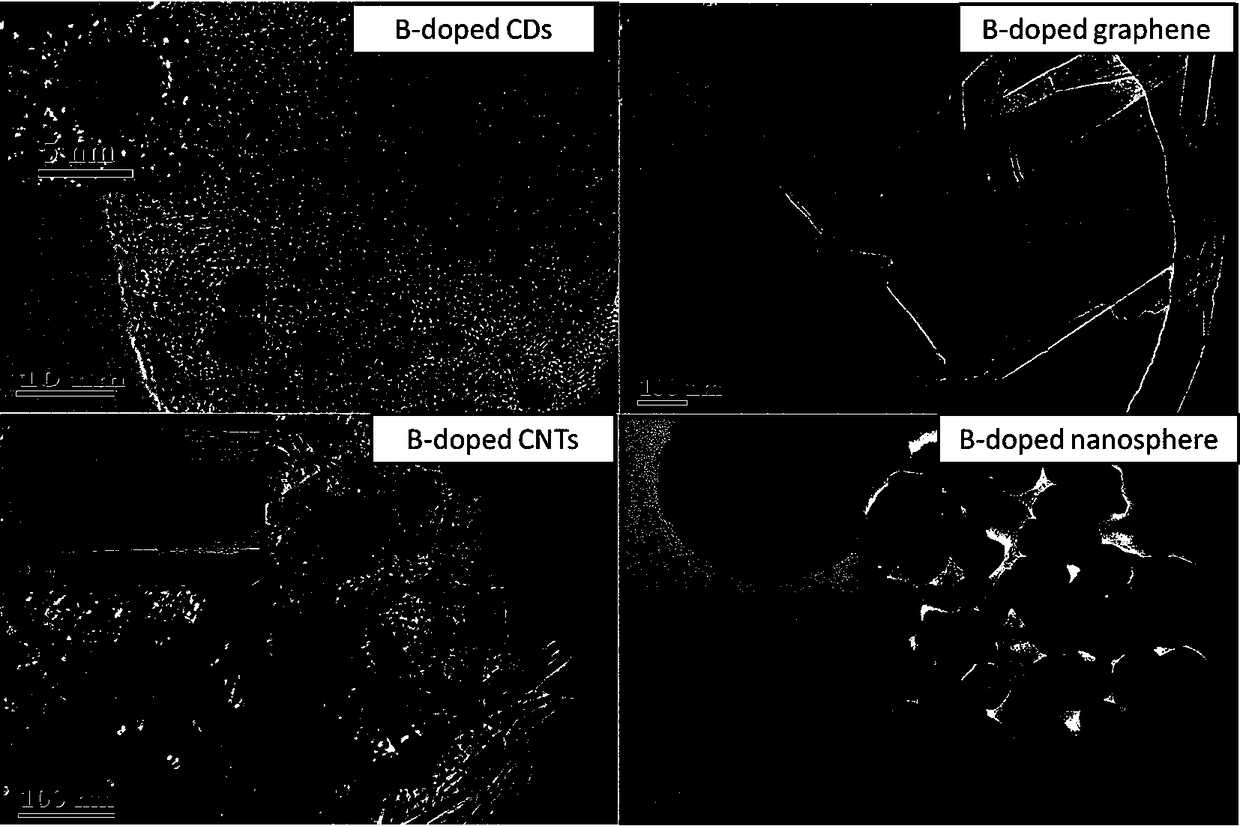

[0029] (2) Fill the carbon dots in a boron-containing graphite crucible, seal the thread and place it in the constant temperature zone of the intermediate frequency graphitization furnace. Under the protection of high-purity argon, keep the constant pressure at 0.04MPa, and then pump the high-purity argon into it. The gas is circulated twice to ensure that all the air is discharged; then...

Embodiment 2

[0031] A method for preparing an atomic crystal boron-doped carbon material, comprising the steps of:

[0032] (1) Boron is introduced into the graphite crucible. The specific process is: first knead 10% nano-boron powder, 35% coal-based pitch, and 55% coke powder at a temperature of 160°C, cool the kneaded material to room temperature, then crush it to 120 μm, and then place it in the mold Molded, then carbonized and pre-graphitized, the maximum temperature is lower than 2000 °C. Finally, the boron-containing graphite block is processed into a screw-sealable crucible;

[0033](2) Fill the graphene in the boron-containing graphite crucible, seal the thread and place it in the constant temperature zone of the intermediate frequency graphitization furnace. Under the protection of high-purity argon, keep the constant pressure at 0.1MPa, and then pump the high-purity argon into it. The gas is circulated twice to ensure that all the air is discharged; then the temperature is rais...

Embodiment 3

[0035] A method for preparing an atomic crystal boron-doped carbon material, comprising the steps of:

[0036] (1) Boron is introduced into the graphite crucible. The specific process is: first knead 20% boron carbide, 35% coal-based pitch, and 45% coke powder at a temperature of 170°C, cool the kneaded material to room temperature, then crush it to 150 μm, and then place it in a mold for isostatic pressing Forming, then carbonization and pre-graphitization, the maximum temperature is lower than 1900 °C. Finally, the boron-containing graphite block is processed into a screw-sealable crucible;

[0037] (2) Fill the carbon nanotubes in the boron-containing graphite crucible, seal the thread and place it in the constant temperature zone of the intermediate frequency graphitization furnace. The argon gas is circulated twice to ensure that all the air is discharged; then the temperature is raised to 2200°C at 5°C / min, and the temperature is kept constant for 1.0h. After the const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com