Modified polyurethane resin and preparation method thereof as well as modified polyurethane artificial leather and application

A polyurethane resin and polyurethane technology, applied in the field of polyurethane resin, can solve the problems of limited reaction conditions, insignificant improvement of mechanical properties, complicated operation, etc., and achieve the effects of reducing expansion, simple and easy preparation method, and increasing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

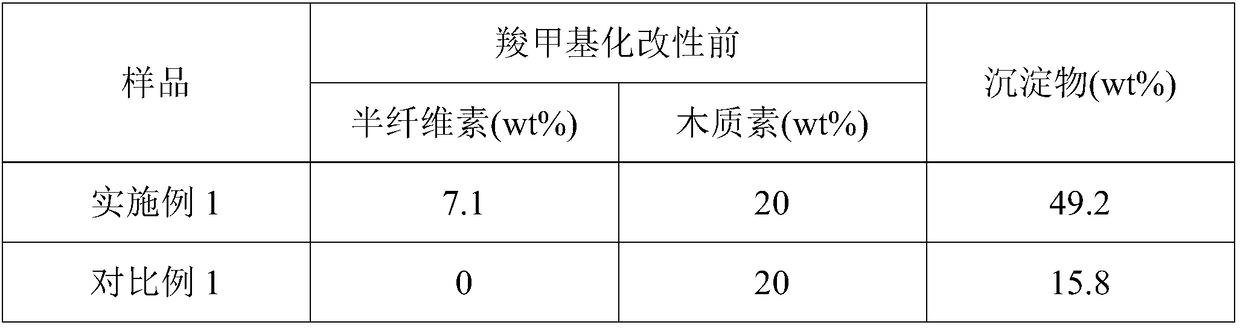

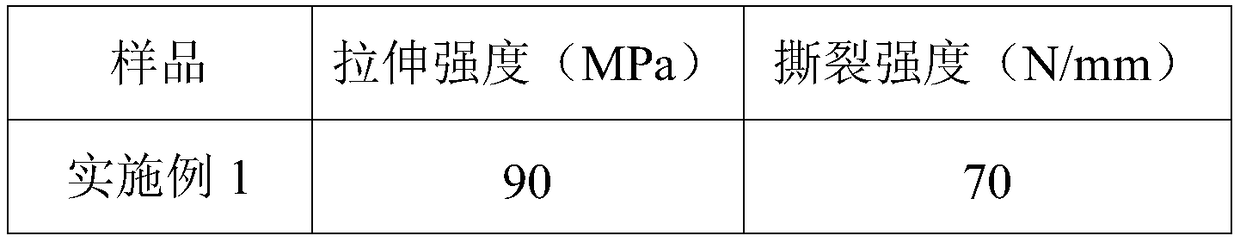

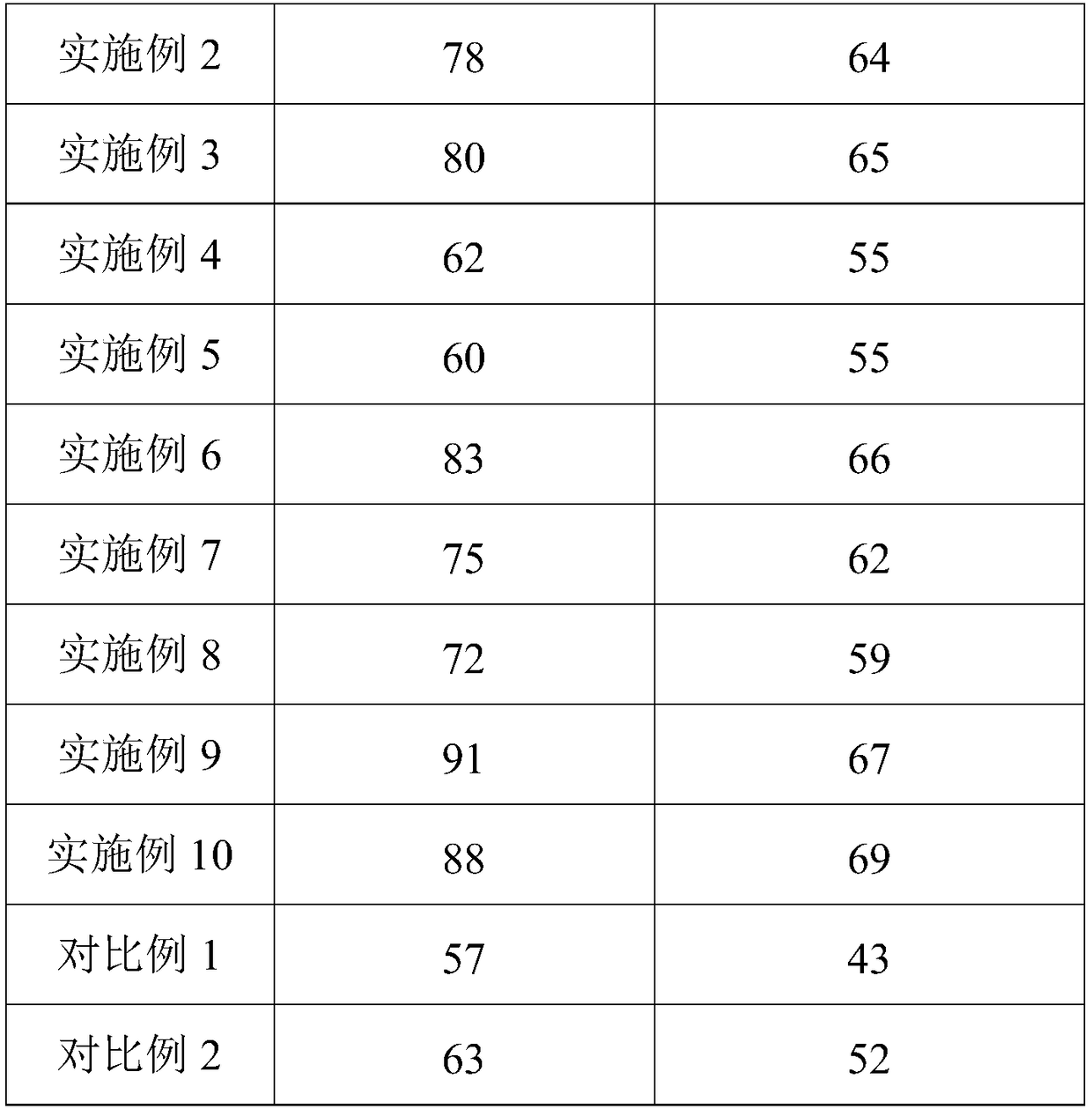

[0059] A modified polyurethane resin, in which 10wt% micronano lignocellulose and 1wt% graphene material are dispersed, and the mass ratio of graphene material to micronano lignocellulose is 0.1:1.

[0060] Wherein, the micro-nano lignocellulose includes 20wt% lignin, the length of the micro-nano lignocellulose is 2 μm, and the diameter is 100 nm; the graphene material is prepared by a mechanical exfoliation method, and the average sheet thickness is 6 nm.

[0061] Its preparation method is as follows:

[0062] (1) adding the cellulose raw material containing 20wt% lignin into acetone and heating under reflux for 20min to obtain a raw material dispersion with a concentration of 10wt%;

[0063] (2) Add graphene material in the raw material dispersion, then peel off and grind through sand milling to obtain the first pretreatment product;

[0064] (3) adding polyurethane resin accounting for 2wt% of the total mass of the polyurethane resin to the first pretreatment product, and ...

Embodiment 2-8

[0068] The only difference with Example 1 is that in the modified polyurethane resin provided by this embodiment, the mass percentage of graphene material is 0.1% (the mass ratio of graphene material and micronano lignocellulose is 0.01:1 , embodiment 2), 10% (the mass ratio of graphene material and micronano lignocellulose is 1:1,

Embodiment 3

[0069] Embodiment 3), 12% (the mass ratio of graphene material and micro-nano lignocellulose is 1.2:1, embodiment 4), in the modified polyurethane resin that present embodiment provides, do not comprise graphene material (implementation Example 5).

[0070] The only difference from Example 1 is that, while keeping the mass ratio of the graphene material and the micronano lignocellulose at 0.1:1, the modified polyurethane resin provided by this example includes a mass percentage of 0.1% micronano lignocellulose (embodiment 6), 20% micronano lignocellulose (embodiment 7), 24% micronano lignocellulose (embodiment 8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com