Preparation method and application in cigarettes of cigarette mango perfume

A mango and spice technology is applied in the field of preparation of mango spice for cigarettes, and achieves the effects of increasing sweetness, comfortable aftertaste, and reducing irritation and miscellaneous air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

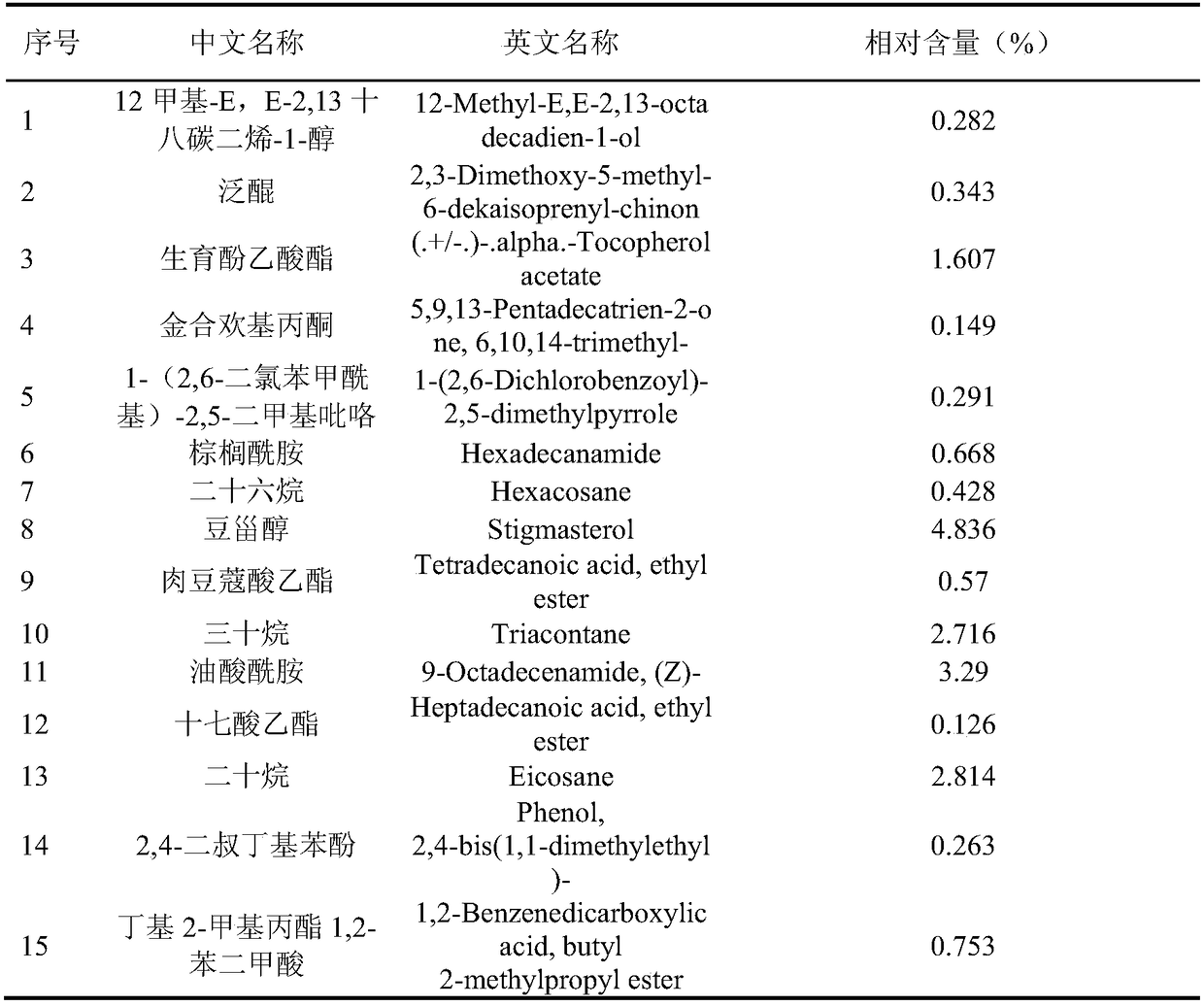

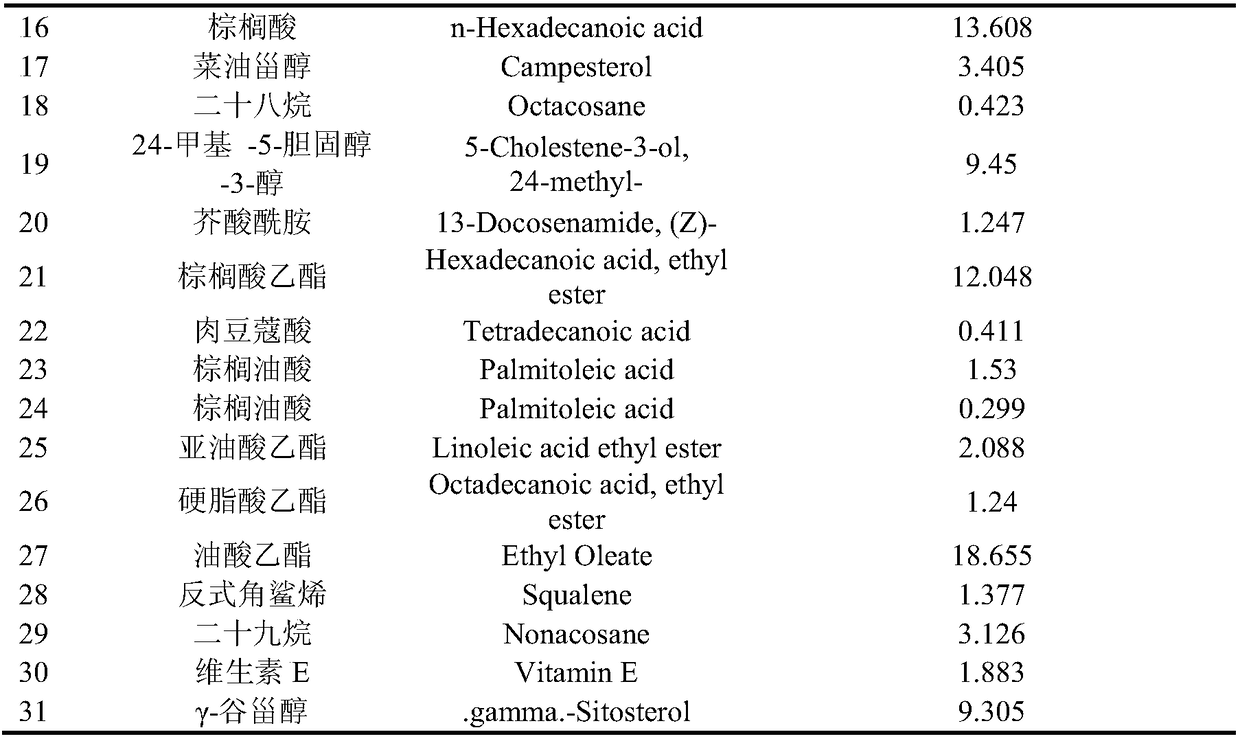

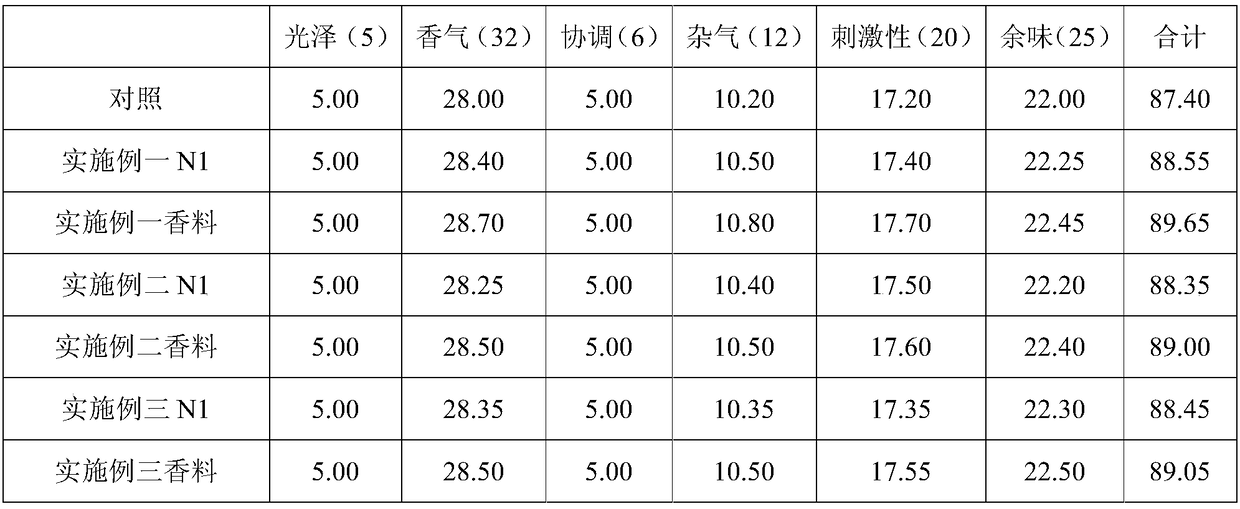

Embodiment 1

[0026] Fresh ripe mangoes were taken, peeled, cut into uniform slices, placed in an oven, and dried at 50°C for 12 hours. Take the dried mango slices, pulverize them into coarse powder, and pass through a 10-mesh stainless steel sieve. Accurately weigh 100g of mango powder, wrap it with filter paper and put it into a Soxhlet extractor, add 500mL of 90% ethanol, heat at 80°C, and heat to reflux for 2h. Filter and distill the filtrate under reduced pressure until no ethanol flows out to obtain mango extract. Accurately weigh 10g of mango extract and place it in a 1000mL beaker, add 500mL of 20% ethanol to dissolve (N1). After the dissolution is complete, use a 50nm ceramic microfiltration membrane to filter, and the interception section is N2; the microfiltration membrane permeate is then filtered with a 100kd organic membrane, and the interception section is recorded as N3, and the permeation section is recorded as N4. Take the N3 part and distill it under reduced pressure to...

Embodiment 2

[0028] Fresh ripe mangoes were taken, peeled, cut into uniform slices, placed in an oven, and dried at 50°C for 12 hours. Take the dried mango slices, pulverize them into coarse powder, and pass through a 10-mesh stainless steel sieve. Accurately weigh 50g of mango powder, wrap it with filter paper and put it into a Soxhlet extractor, add 500mL of 50% ethanol, heat at 50°C, and heat to reflux for 2.5h. Filter and distill the filtrate under reduced pressure until no ethanol flows out to obtain mango extract. Accurately weigh 10g of mango extract and place it in a 1000mL beaker, add 500mL of 20% ethanol to dissolve (N1). After the dissolution is complete, use a 200nm ceramic microfiltration membrane to filter, and the interception section is N2; the microfiltration membrane permeate is then filtered with a 500kd organic membrane, and the interception section is recorded as N3, and the permeation section is recorded as N4. Take the N3 part and distill it under reduced pressure ...

Embodiment 3

[0030] Fresh ripe mangoes were taken, peeled, cut into uniform slices, placed in an oven, and dried at 50°C for 12 hours. Take the dried mango slices, pulverize them into coarse powder, and pass through a 10-mesh stainless steel sieve. Accurately weigh 150g of mango powder, wrap it with filter paper and put it into a Soxhlet extractor, add 450mL of 100% ethanol (absolute ethanol), heat at 90°C, and heat to reflux for 1h. Filter and distill the filtrate under reduced pressure until no ethanol flows out to obtain mango extract. Accurately weigh 10g of mango extract and place it in a 1000mL beaker, add 500mL of 20% ethanol to dissolve (N1). After the dissolution is complete, use a 100nm ceramic microfiltration membrane to filter, and the cut-off section is N2; the microfiltration membrane permeate is then filtered with a 10kd organic membrane, and the cut-off section is recorded as N3, and the permeated section is recorded as N4. Take the N3 part and distill it under reduced pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com