A kind of multi-layer vascular stent and preparation method thereof

A vascular stent and inner tube technology, applied in the field of multi-layer vascular stent and its preparation, can solve the problems of lack of repairing blood vessel function, foreign body reaction of stent, single stent function, etc., so as to prolong antithrombotic time, promote healing and repair effect of blood vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

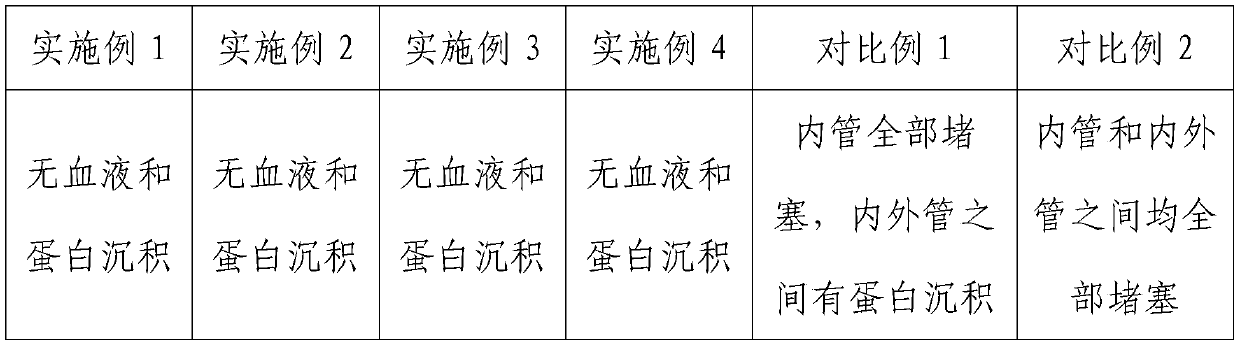

Examples

Embodiment 1

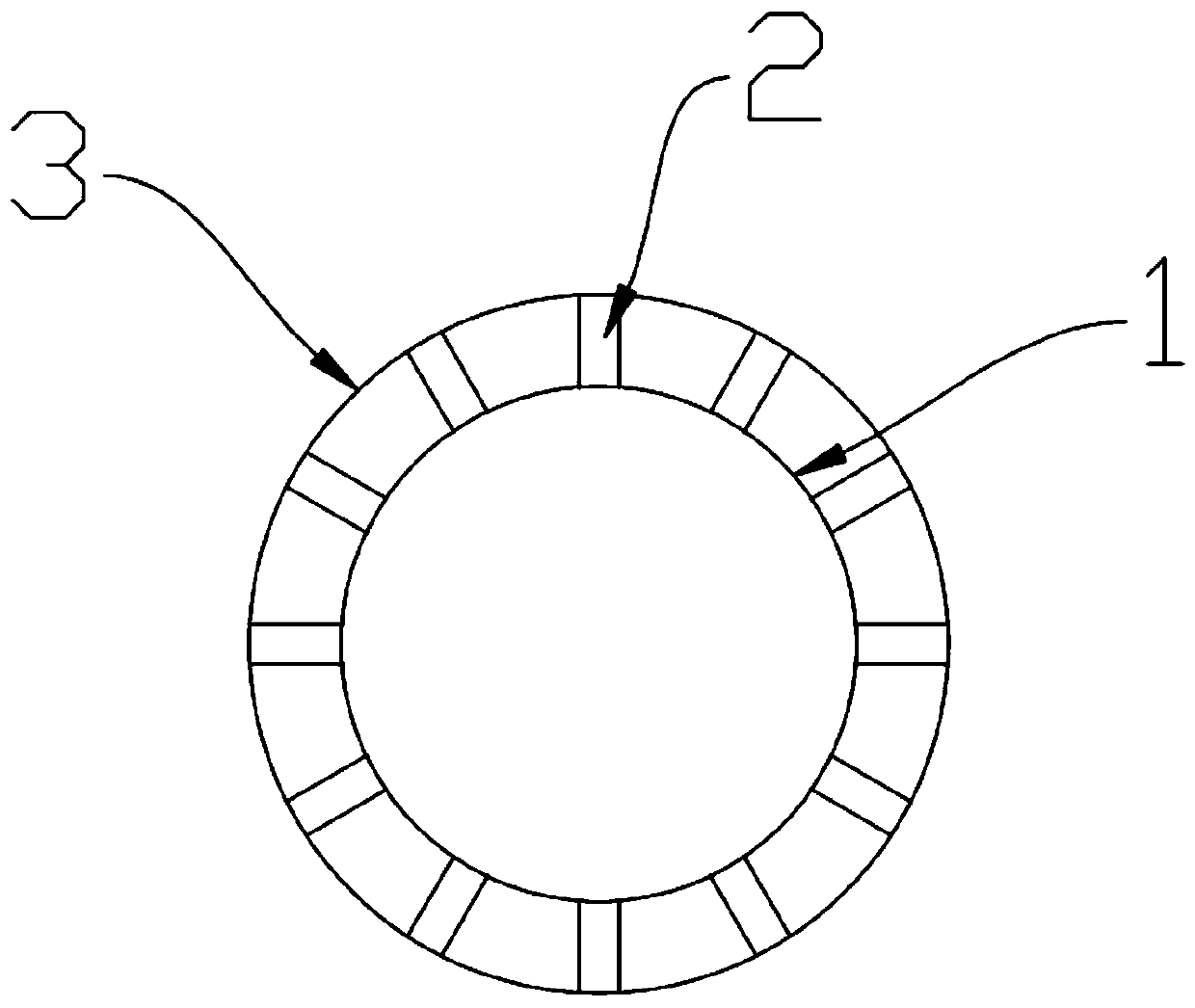

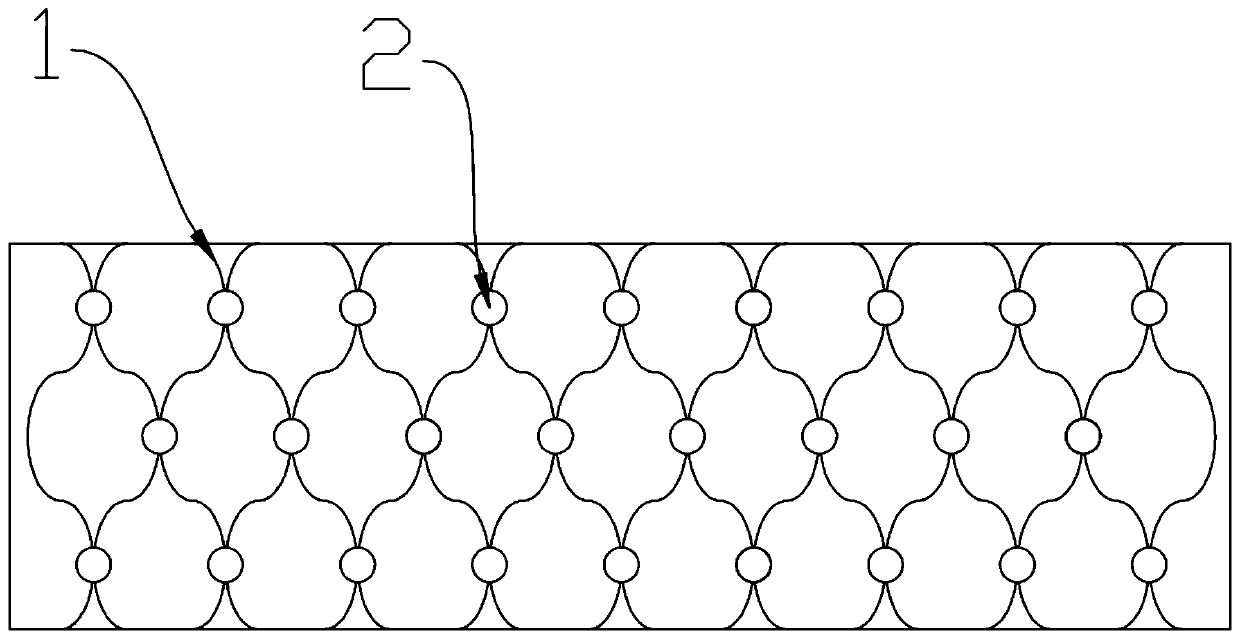

[0024] (a) Add polylactic acid with a molecular weight of 900,000 Da into the extruder, extrude a pipe with a wall thickness of 0.2 mm, cut the pipe with a laser, and cut the wall of the pipe into a network structure to obtain the inner pipe 1, the inner pipe The inner diameter of 1 is 4 mm, the inner tube 1 is placed in the mold for preparing the support bar 2, the shape memory polymer in the molten state is added to the mold, cooled to room temperature, and dried, and the outer wall of the inner tube 1 is made into a support bar 2. A plurality of said shaped support bars 2 are radially distributed on the outer surface of the inner tube 1, the diameter of the support bars 2 is 0.05 mm, and the distance between adjacent support bars 2 is 0.5 mm; The solution of rapamycin is coated on the outer surface of the support bar 2 and dried; then the inner tube 1 is placed in the mold for preparing the outer tube 3, the shape memory polymer is added to the mold, cooled to room temperatu...

Embodiment 2

[0030] (a) Add polylactic acid with a molecular weight of 1 million Da into the extruder, extrude a pipe with a wall thickness of 0.2 mm, and cut the pipe with a laser to obtain an inner pipe 1 whose inner diameter is 4 mm. Place the mold for preparing the support bar 2, add the shape memory polymer in the molten state into the mold, cool to room temperature, dry, and make the support bar 2 on the outer wall of the inner tube 1, and a plurality of the shape memory polymers 2 Distributed radially on the outer surface of the inner tube 1, the diameter of the support bars 2 is 0.01 mm, and the distance between adjacent support bars 2 is 0.4 mm; subsequently, the solution loaded with rapamycin is coated on the support The outer surface of the bar 2 is dried; then the inner tube 1 is placed in the mold for preparing the outer tube 3, the shape memory polymer is added to the mold, cooled to room temperature, and dried, and the inner tube 1 is placed at the side of the support bar 2 f...

Embodiment 3

[0034](a) Add polylactic acid with a molecular weight of 900,000 Da into the extruder, extrude a pipe with a wall thickness of 0.1 mm, and cut the pipe with a laser to obtain an inner pipe 1 whose inner diameter is 3 mm. Place the mold for preparing the support bar 2, add the shape memory polymer in the molten state into the mold, cool to room temperature, dry, and make the support bar 2 on the outer wall of the inner tube 1, and a plurality of the shape memory polymers 2 Distributed radially on the outer surface of the inner tube 1, the diameter of the support bar 2 is 0.1 mm, and the distance between adjacent support bars 2 is 0.5 mm; subsequently, the solution loaded with rapamycin is coated on the support The outer surface of the bar 2 is dried; then the inner tube 1 is placed in the mold for preparing the outer tube 3, the shape memory polymer is added to the mold, cooled to room temperature, and dried, and the inner tube 1 is placed at the side of the support bar 2 far aw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com