Preparation method for hydrophilic oil-water separation membrane imitating cobweb structure

An oil-water separation membrane and hydrophilic technology, which is applied in the field of environmental protection and chemical separation, can solve the problems of multi-walled carbon nanotubes, such as easy self-agglomeration, poor mechanical processing performance, and low mechanical strength, to overcome low mechanical strength and effectively Hydrophilic modification, effective dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

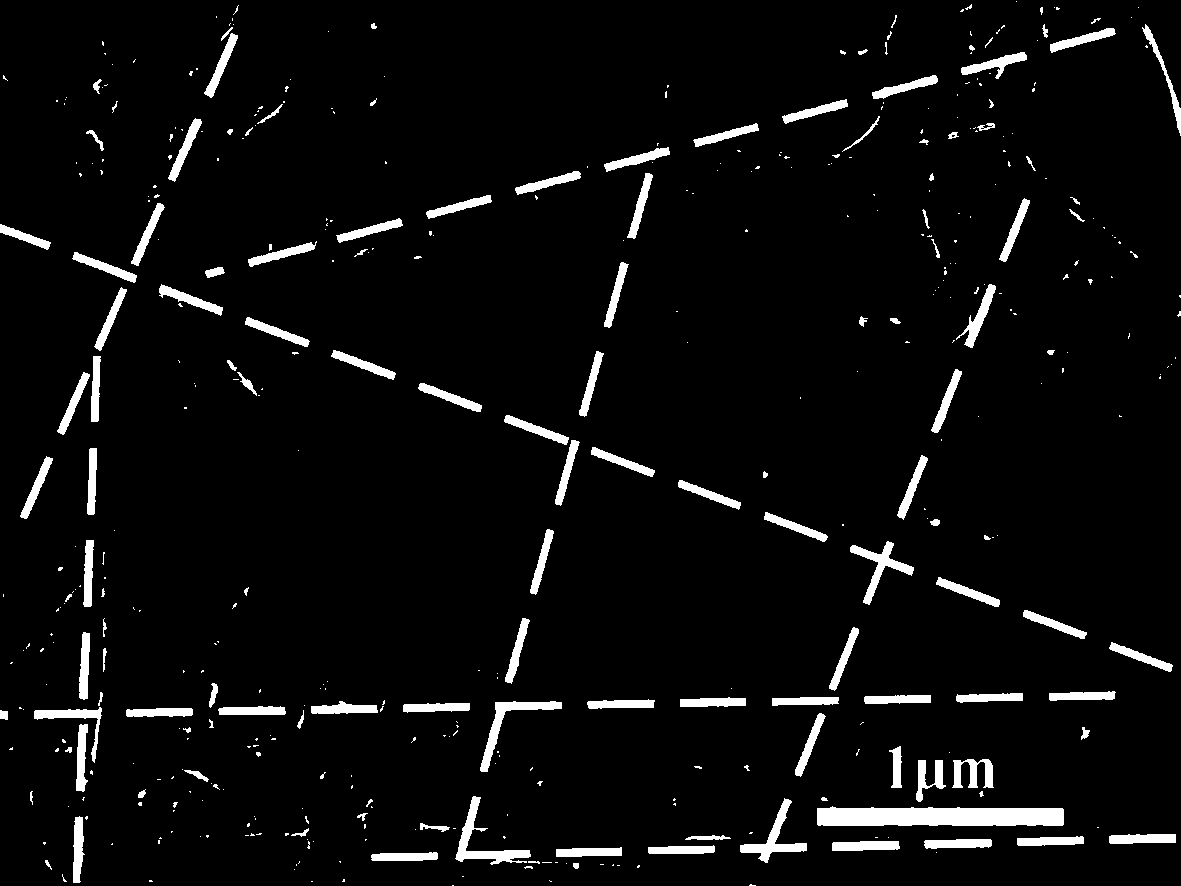

Image

Examples

Embodiment 1

[0030] A preparation method of a hydrophilic oil-water separation membrane imitating a spider web structure, comprising the steps of:

[0031] a) Dispersion of multi-walled carbon nanotubes: add 0.5 mL of perchloric acid per gram of multi-walled carbon nanotubes, react the mixture at 120 °C for 6 h, and deionize the obtained multi-walled carbon nanotubes Rinse with water 10 times until the pH is neutral, and dry in a vacuum oven at 60 °C for 5 h. Add 0.5 g of dispersed multi-walled carbon nanotubes per liter of water to obtain a black liquid. The black liquid was ultrasonically oscillated for 5 h to obtain a fully dispersed multi-walled carbon nanotube dispersion;

[0032] b) Purification of the dispersion of multi-walled carbon nanotubes: centrifuging and purifying the obtained multi-walled carbon nanotubes dispersion at 9000 rad / min for 30 min, and taking the supernatant to obtain a completely dispersed multi-walled carbon nanotubes dispersion;

[0033] c) Preparation of h...

Embodiment 2

[0036] A preparation method of a hydrophilic oil-water separation membrane imitating a spider web structure, comprising the steps of:

[0037] a) Dispersion of multi-walled carbon nanotubes: add 5 mL of nitric acid per gram of multi-walled carbon nanotubes, react the mixture at 140 °C for 3 h, and rinse the obtained multi-walled carbon nanotubes with deionized water 10 times until the pH was neutral, and dried in a vacuum oven at 80°C for 3 h. Add 1 g of dispersed multi-walled carbon nanotubes per liter of water to obtain a black liquid. The black liquid was ultrasonically oscillated for 8 h to obtain a fully dispersed multi-walled carbon nanotube dispersion;

[0038] b) Purification of the dispersion of multi-walled carbon nanotubes: centrifuging and purifying the obtained multi-walled carbon nanotubes dispersion at 10,000 rad / min for 20 min, and taking the supernatant to obtain a completely dispersed multi-walled carbon nanotubes dispersion;

[0039] c) Preparation of hydr...

Embodiment 3

[0042] A preparation method of a hydrophilic oil-water separation membrane imitating a spider web structure, comprising the steps of:

[0043] a) Dispersion of multi-walled carbon nanotubes: 3 mL of concentrated sulfuric acid was added to each gram of multi-walled carbon nanotubes, and the mixture was reacted at 160 °C for 4 h, and the obtained multi-walled carbon nanotubes were deionized water Rinse 15 times until the pH is neutral, and dry in a vacuum oven at 80 °C for 5 h. Add 2 g of dispersed multi-walled carbon nanotubes per liter of water to obtain a black liquid. The black liquid was ultrasonically oscillated for 12 hours to obtain a completely dispersed multi-walled carbon nanotube dispersion;

[0044] b) Purification of the dispersion of multi-walled carbon nanotubes: centrifuging and purifying the obtained multi-walled carbon nanotubes dispersion at 12000 rad / min for 20 min, and taking the supernatant to obtain a completely dispersed multi-walled carbon nanotubes di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com