Wheel-drive electric vehicle drive-by-wire chassis structure

An electric vehicle, a full-line technology, applied in the direction of electric vehicles, substructures, collectors, etc., can solve the problems of inaccurate distribution of driving torque, unfavorable technology development, and low space utilization, so as to promote deep electrification and intelligence The development of the vehicle, adapting to different road conditions and driving environments, and improving the utilization of chassis space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

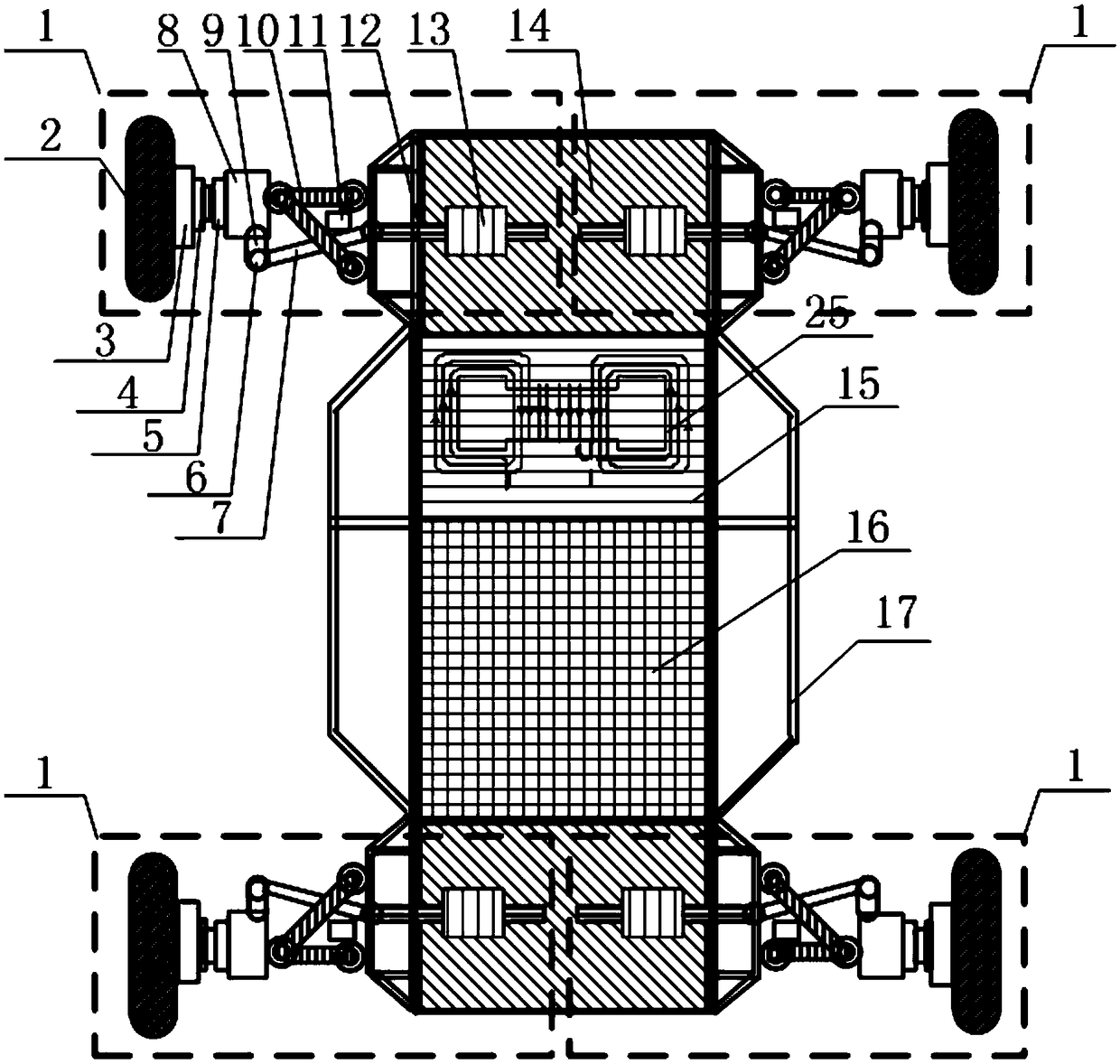

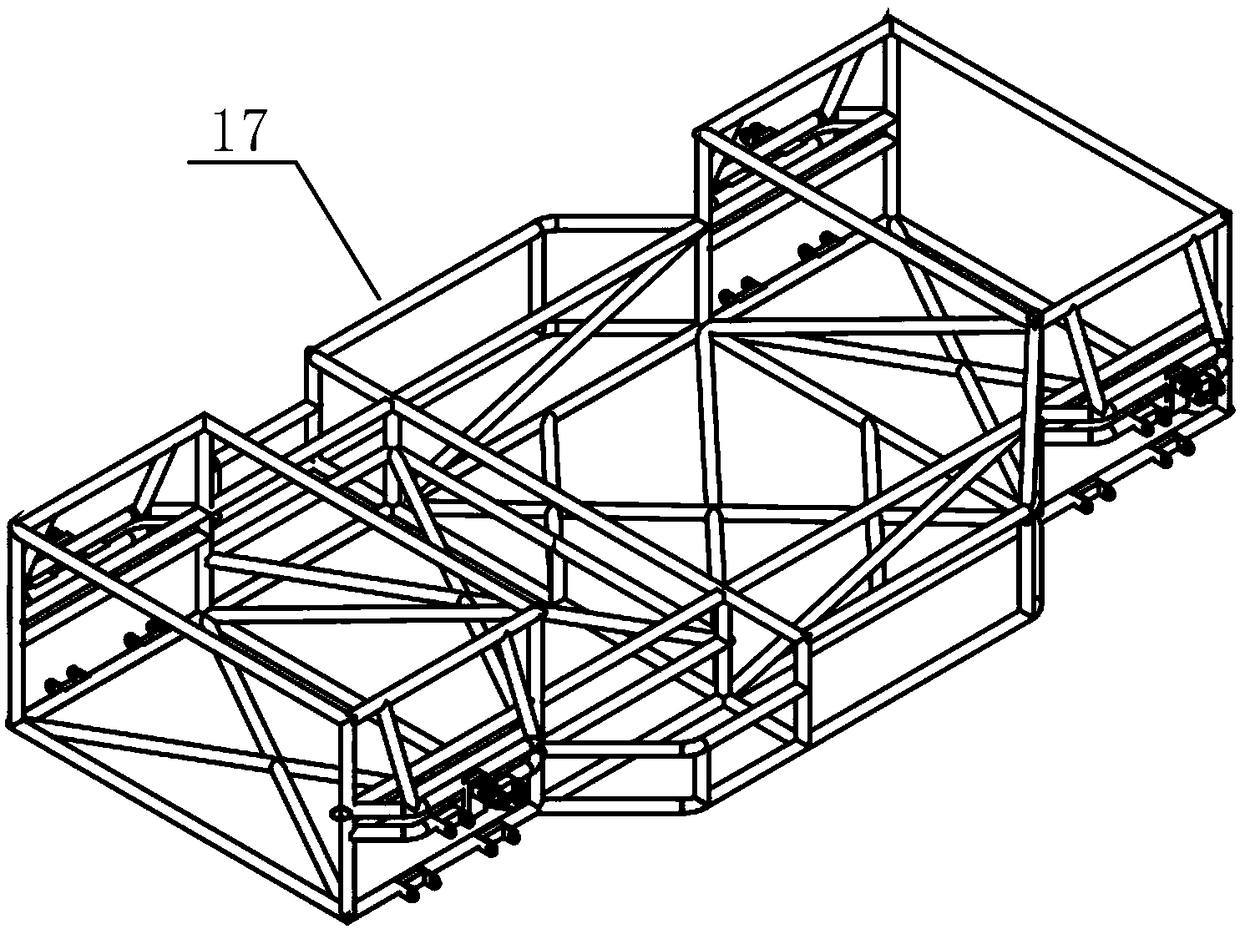

[0021] The present invention is a wheel-drive electric vehicle full control-by-wire chassis structure, such as figure 1 , 2 As shown, including the chassis frame 17, the bottom of the chassis frame 17 is provided with four single-wheel assemblies 1, and the four single-wheel assemblies 1 are respectively located at the four corners of the chassis frame 17, and the two sides of the chassis frame 17 A motor mounting plate 14 matched with the single wheel assembly 1 is provided at each end, and a wireless charging carrying device 15 and a battery placement area 16 are sequentially arranged between the two motor mounting plates 14, and a storage battery is arranged on the battery placement area 16.

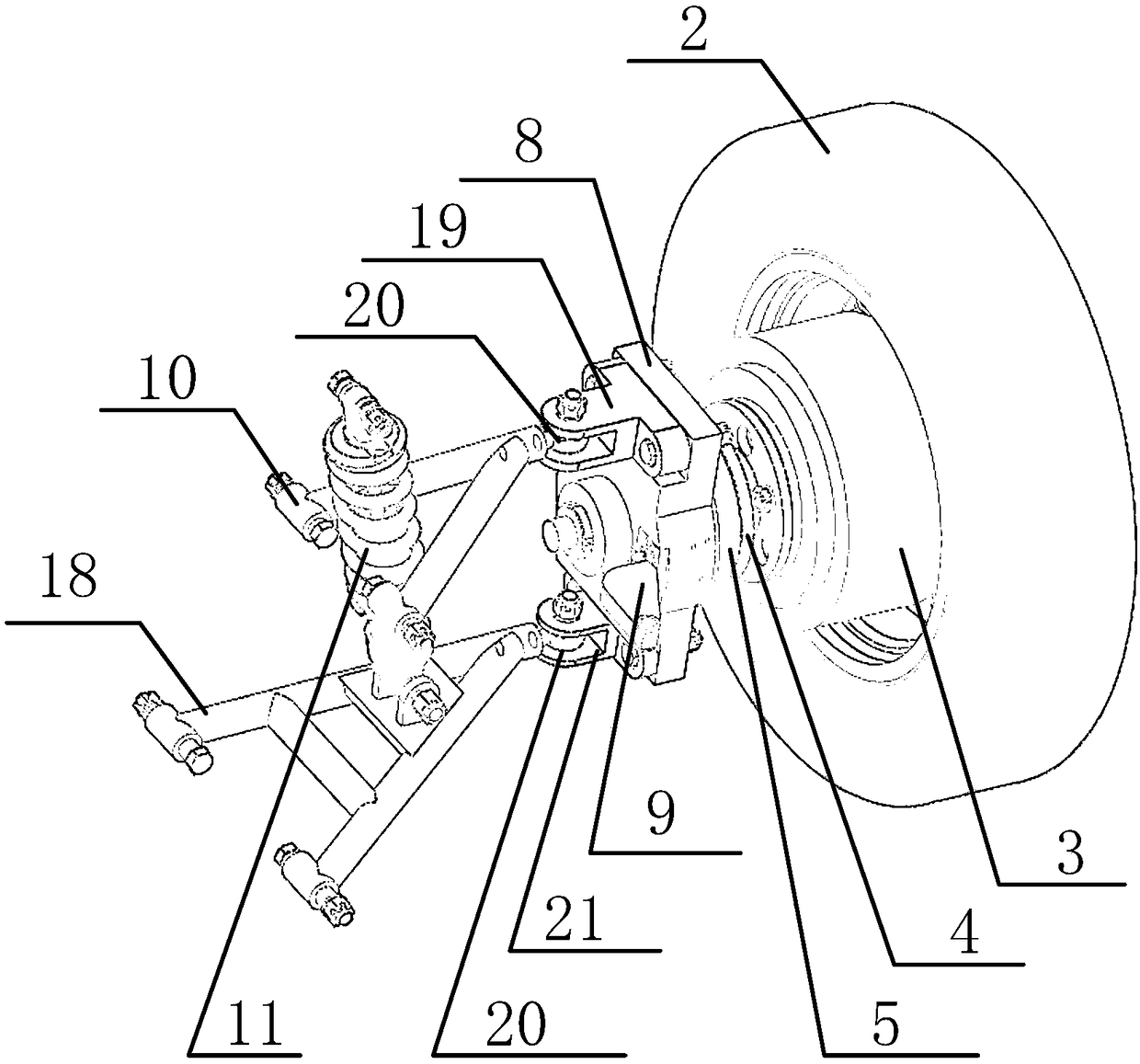

[0022] like image 3 As shown, each single wheel assembly 1 includes a wheel hub 2, and the inner side of the wheel hub 2 is provided with a colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com