Process for producing potassium chloride by using carnallite

A carnallite and potassium chloride technology, applied in the direction of alkali metal chlorides, etc., can solve the problems of high consumption of fresh water and low yield of potassium chloride, so as to ensure complete decomposition, reduce the content of potassium chloride, and reduce the consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

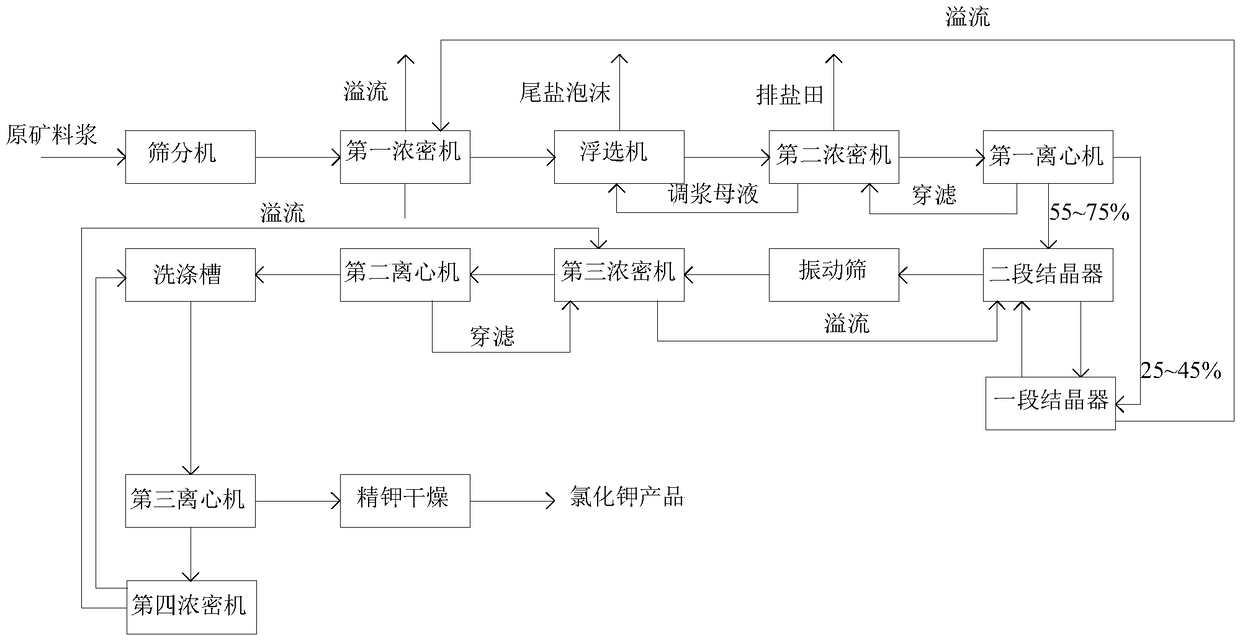

[0029] The present embodiment provides a kind of technique that utilizes carnallite ore to produce Potassium Chloride, comprises the steps:

[0030] S1 flotation: Carnallite ore is processed by flotation to produce low-sodium carnallite.

[0031] In order to improve the recovery rate of potassium chloride in the overall process, the flotation treatment in this step is preferably a reverse flotation treatment process. Wherein, the reverse flotation treatment process includes the following steps in turn:

[0032] S11 Crushing and screening: The large pieces of carnallite ore obtained by mining are crushed and screened to form small pieces of carnallite ore. Specifically, the size of the small pieces of carnallite ore is less than 20 mm.

[0033] S12 Preparation of slurry: Mix small pieces of carnallite with saturated brine, and use the first thickener to achieve preliminary settlement to form bottom slurry.

[0034] S13 Flotation treatment: Add the slurry to the flotation mach...

Embodiment 2

[0052] This embodiment is roughly the same as Embodiment 1, except that in the S2 crystallization process, 55% of the low-sodium carnallite is added to the first-stage crystallizer, and 45% of the low-sodium carnallite is added to the second-stage crystallizer.

[0053] After processing and calculation, the yield of potassium chloride in the present embodiment is 75%.

Embodiment 3

[0055] This embodiment is roughly the same as Embodiment 1, except that in the S2 crystallization process, 75% of low-sodium carnallite is added to the first-stage crystallizer, and 25% of low-sodium carnallite is added to the second-stage crystallizer.

[0056] After processing and calculation, the yield of potassium chloride in the present embodiment is 78%.

[0057] Visible by embodiment one~embodiment three, the present invention adopts two sections of crystallizers to be connected in series to realize in the crystallization process, and the fresh water amount that adopts is identical with the fresh water amount that adopts one section of crystallizers, not only makes low after flotation treatment Sodium carnallite is completely decomposed, and the content of potassium chloride in the overflow liquid is reduced, so that the yield of potassium chloride in the present invention is increased to more than 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com