Method for continuously oxidizing organic wastewater under microwave assistance

A technology for oxidation treatment and organic wastewater, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of inability to realize online regeneration, poor COD removal effect, low regeneration temperature and pressure, etc. Achieve the effect of easy automatic production, low processing cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Air Oxidation of Simulated Wastewater Containing Phenols Catalyzed by Continuous Microwave Assisted Activated Carbon Supported Copper Catalysts

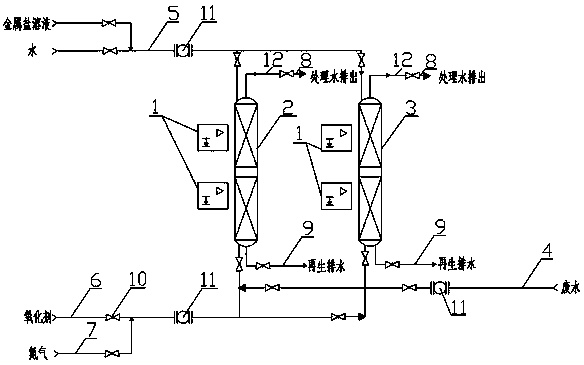

[0033] A device for continuous microwave-assisted oxidation treatment of organic wastewater, see figure 1 Shown, comprise reaction device, and the feed pipe that links to each other with reaction device respectively, discharge pipe and microwave generator 1; The device B 3 is composed of; feed pipe includes waste water feed pipe 4, regeneration feed pipe 5, oxidant feed pipe 6 and nitrogen feed pipe 7; discharge pipe includes treated water discharge pipe 8 and regeneration drain pipe 9; waste water Feed pipe 4, regeneration drain pipe 9, oxidant feed pipe 6 and nitrogen feed pipe 7 are all communicated with the bottom of reactor A 2 and reactor B 3 respectively, treated water outlet pipe 8, regeneration feed pipe 5 are respectively Both communicate with the upper part of reactor A 2 and reactor B 3; reactor A 2 and reactor B ...

Embodiment 2

[0048] Air Oxidation of Simulated Wastewater Containing Phenol Catalyzed by Continuous Microwave Assisted Activated Carbon Supported Iron Catalyst

[0049] The same operating form and apparatus as in Example 1 were adopted. In order to compare the treatment effects of different catalysts, two cycle operations were carried out, and each cycle treated wastewater for 72 hours.

[0050] (1) Granular activated carbon enters the interior of the reactor from the upper end of the reactor, and the reactor is filled to form a fixed bed; both reactors are filled with 50g of granular activated carbon.

[0051] (2) Take 312ml of 65% concentrated nitric acid solution and add water to 500ml to make a solution. Weigh 100g of ferric nitrate nonahydrate into the solution and stir to dissolve. Feed the ferric nitrate solution prepared from the upper part of the reactor A, and the flow rate is controlled at 2-3BV / h. After passing through, continue to pass into 200ml of water. Empty the water i...

Embodiment 3

[0061] Air Oxidation of Simulated Wastewater Containing Phenol Catalyzed by Continuous Microwave Assisted Activated Carbon Supported Manganese Catalyst

[0062] The same operating form and apparatus as in Example 1 were adopted. In order to compare the treatment effects of different catalysts, two cycle operations were carried out, and each cycle treated wastewater for 72 hours.

[0063] (1) Granular activated carbon enters the interior of the reactor from the upper end of the reactor, and the reactor is filled to form a fixed bed; both reactors are filled with 50g of granular activated carbon.

[0064] (2) Put 44g of manganese nitrate into 500ml of water and stir to dissolve. Pass through the prepared manganese nitrate solution from the upper part of the reactor A, and the flow rate is controlled at 2-3BV / h. After passing through, continue to pass into 200ml of water. Empty the water in the reactor, and then blow it dry with air. Introduce nitrogen, turn on the microwave,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com