Method for treating waste water in turbulent electric flocculation way

A technology for wastewater treatment and electrocoagulation, which is applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of difficult separation and high COD value of oil production sewage, achieve high stability, improve material applicability, The effect of high operational flexibility and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

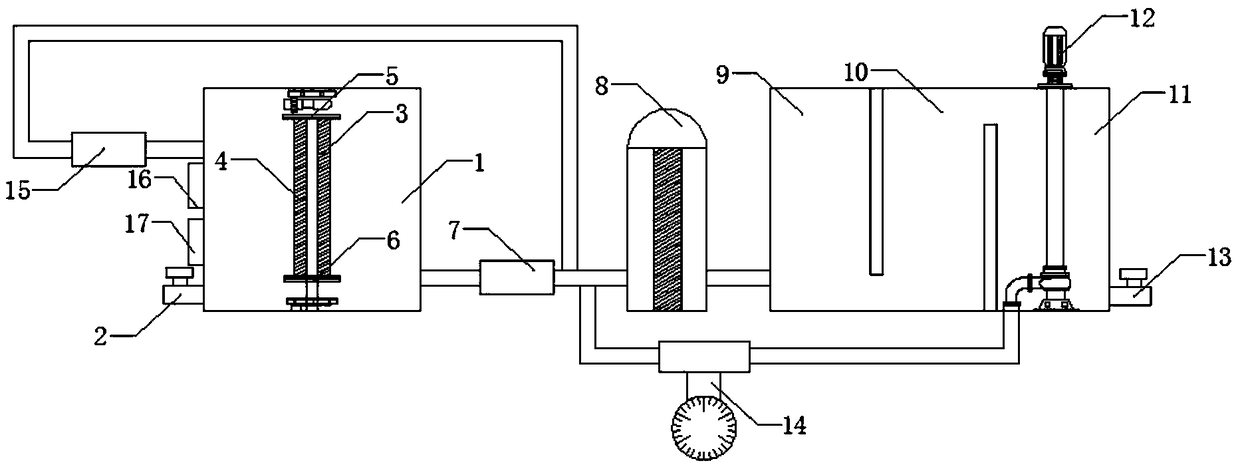

[0023] The invention provides the following technical solutions: a method for treating wastewater by turbulent electrocoagulation, comprising the following steps:

[0024] S1: Open the regulating valve of the water inlet pipe 2, and pass the waste water into the turbulent electroflocculation tank 1 through the water inlet pipe 2;

[0025] S2: Time the first electromagnetic commutator 7 and the second electromagnetic commutator 15 through the first timing switch 16 and the second timing switch 17 respectively, so that the first electromagnetic commutator 7 and the second electromagnetic commutator 15 Periodically switch the valve position state;

[0026] S3: switch the valve positions of the first electromagnetic commutator 7 and the second electromagnetic commutator 15, and under the action of the circulation pump 12, the electrolyzed water in the turbulent electrocoagulation tank 1 is pumped into the circulation tank through the filter 8 middle;

[0027] S4: Wastewater form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com