Inorganic soft porcelain and preparation method thereof

An inorganic and soft porcelain technology, applied in the field of construction and decorative materials, can solve the problems of poor scratch resistance, difficult thickness control, large color difference, etc., and achieve the effects of excellent performance, single-line production capacity expansion, and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

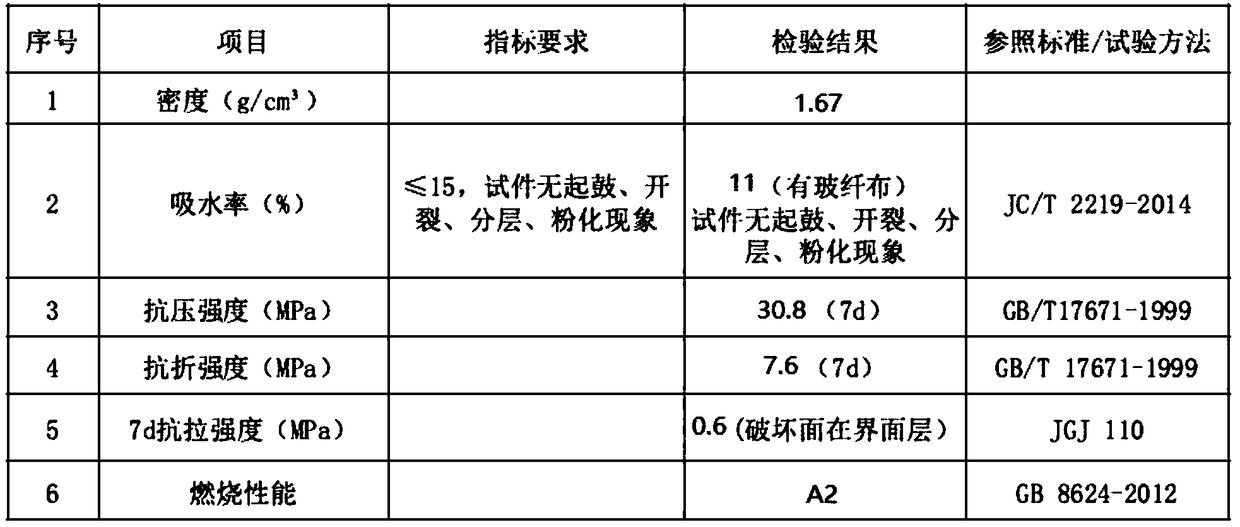

Examples

Embodiment 1

[0052] A kind of inorganic soft porcelain, its raw material contains each component of following weight ratio:

[0053] 200 parts of clay;

[0054] 70 parts of 200 mesh fly ash;

[0055] 260 parts of 525 cement;

[0056] 15 parts each of glass fiber cloth and rock wool fiber;

[0057] 40 parts of vinyl ester resin;

[0058] 30 parts of sawdust;

[0059] 1.2 parts of silicone emulsion waterproofing agent.

[0060] Experiments have proved that after three years of use, the overall shape and structure of the inorganic soft porcelain have hardly changed, but the wear resistance and compactness have slight changes, and the surface has small unevenness. This shows that the size ratio of fly ash particles is inappropriate, with more large particles and less small particles.

Embodiment 2

[0062] A kind of inorganic soft porcelain, its raw material contains each component of following weight ratio:

[0063] 50 parts each of quartz powder and kaolin;

[0064] 50 parts of mixed powder of silica fume and ceramic powder, the mass ratio of silica fume and ceramic powder is 1:1, both silica fume and ceramic powder are composed of 200 mesh and 300 mesh particles in equal proportions;

[0065] 180 parts of 625 cement;

[0066] 20 parts of mineral wool fiber;

[0067] 60 parts of vinyl ester resin;

[0068] 0.8 parts of silicone emulsion waterproofing agent.

[0069] Experiments have proved that after three years of use, the overall shape and structure of the inorganic soft porcelain material has slightly changed, and there is a slight drop phenomenon, and the thickness of the material is the same as before use. It shows that the inorganic soft porcelain has excellent weather resistance, wear resistance and compactness. The size ratio of silica fume and ceramic powde...

Embodiment 3

[0071] A kind of inorganic soft porcelain, its raw material contains each component of following weight ratio:

[0072] 60 parts each of quartz powder, kaolin and clay;

[0073] 80 parts of mixed powder of silica fume and fly ash, the mass ratio of silica fume and fly ash is 1:1, both silica fume and fly ash are composed of 200 mesh and 300 mesh particles in equal proportions;

[0074] 300 parts of 425 cement;

[0075] 12.5 parts each of mineral wool fiber and rock wool fiber;

[0076] 50 parts of vinyl ester resin;

[0077] 10 parts each of straw and bamboo powder;

[0078] 0.9 parts of silicone emulsion waterproofing agent.

[0079] It has been proved by experiments that after three years of use, the overall shape and structure of the inorganic soft ceramic material has hardly changed, and the thickness of the material is basically the same as before use, but the surface ceramic material has a slight protrusion, which affects the color, indicating that the powder The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com