Inorganic fiber heat-insulating paste material and preparation method thereof

A technology of inorganic fiber and paste, applied in the direction of coating, etc., can solve the problems of poor fireproof performance, achieve stable performance, low thermal conductivity, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

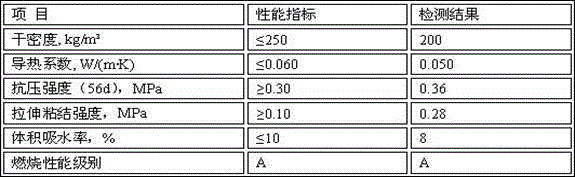

Embodiment 1

[0115] Take 20 kg of vitrified microspheres, 5 kg of sepiolite fiber, 5 kg of fly ash above grade 2, 5 kg of colored sand, 0.2 g of polypropylene fiber, 8 kg of acrylic emulsion, 0.6 kg of film-forming aid, cellulose ether 0.5 kg, 0.1 kg of defoamer, 55.6 kg of water.

[0116] Vitrified beads are produced by Xinyang Shenhui Bentonite Co., Ltd. (the main chemical composition is SiO 2 、Al 2 o 3 , CaO), sepiolite is produced by Leibao Sepiolite Processing Co., Ltd., Wolong District, Nanyang City (a magnesium-rich silicate fiber mineral, whose physical and chemical formula is MgO[Si 12 o 30 ](OH) 4 12H 2 O), the fly ash above grade two is produced by Shanghai Xinghuo Company, the colored sand is the natural colored sand (mainly composed of silica) produced by Shanghai Aobo, and the polypropylene fiber is DL-1 produced by Shanghai Dalu Industrial Co., Ltd. fiber, which plays the role of anti-cracking, the acrylic emulsion is RS-992 emulsion produced by Shanghai Bardford, whic...

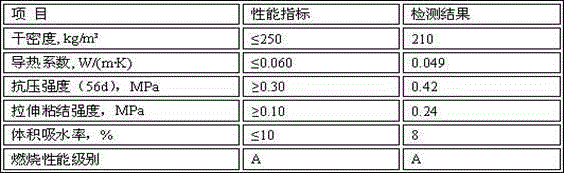

Embodiment 2

[0122] Take 25 kg of vitrified microspheres, 8 kg of sepiolite fiber, 8 kg of fly ash above grade 2, 3 kg of colored sand, 0.3 g of polypropylene fiber, 10 kg of acrylic emulsion, 0.8 kg of film-forming aid, cellulose ether 0.3 kg, 0.05 kg of defoamer, 42.55 kg of water.

[0123] Vitrified beads are produced by Xinyang Shenhui Bentonite Co., Ltd. (the main chemical composition is SiO 2 、Al 2 o 3 , CaO), sepiolite is produced by Leibao Sepiolite Processing Co., Ltd., Wolong District, Nanyang City (a magnesium-rich silicate fiber mineral, whose physical and chemical formula is MgO[Si 12 o 30 ](OH) 4 12H 2 O), the fly ash above grade two is produced by Shanghai Xinghuo Company, the colored sand is the natural colored sand (mainly composed of silica) produced by Shanghai Aobo, and the polypropylene fiber is DL-1 produced by Shanghai Dalu Industrial Co., Ltd. fiber, which plays the role of anti-cracking, the acrylic emulsion is RS-992 emulsion produced by Shanghai Bardford, w...

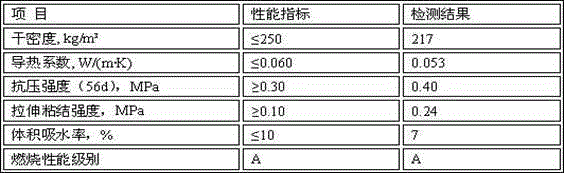

Embodiment 3

[0128] Take 30 kg of vitrified microspheres, 5 kg of sepiolite fiber, 3 kg of fly ash above grade 2, 3 kg of colored sand, 0.5 g of polypropylene fiber, 15 kg of acrylic emulsion, 1.0 kg of film-forming aid, cellulose ether 0.7 kg, 0.2 kg of defoamer, 44.4 kg of water.

[0129] Vitrified beads are produced by Xinyang Shenhui Bentonite Co., Ltd. (the main chemical composition is SiO 2 、Al 2 o 3 , CaO), sepiolite is produced by Leibao Sepiolite Processing Co., Ltd., Wolong District, Nanyang City (a magnesium-rich silicate fiber mineral, whose physical and chemical formula is MgO[Si 12 o 30 ](OH) 4 12H 2 O), the fly ash above grade two is produced by Shanghai Xinghuo Company, the colored sand is the natural colored sand (mainly composed of silica) produced by Shanghai Aobo, and the polypropylene fiber is DL-1 produced by Shanghai Dalu Industrial Co., Ltd. fiber, which plays the role of anti-cracking, the acrylic emulsion is RS-992 emulsion produced by Shanghai Bardford, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com