Method for synthesizing 4-chlorobutyryl chloride

A synthesis method and technology of chlorobutyryl chloride are applied in chemical instruments and methods, preparation of acid halides, preparation of organic compounds, etc., can solve problems such as high cost of raw materials, high operation requirements, reduced yield and the like, and achieve high reaction yield , safe operation, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

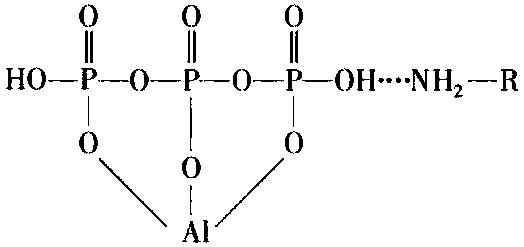

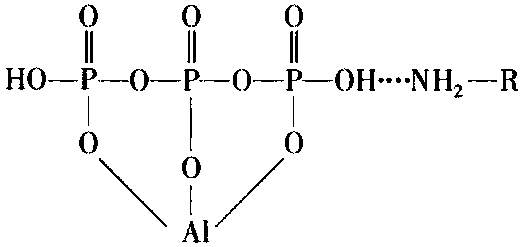

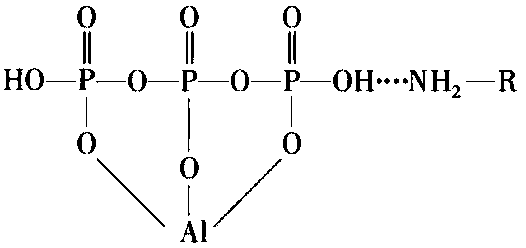

[0030] According to the intercalation reaction characteristics of aluminum dihydrogen tripolyphosphate and organic amine, the method described in Applied Chemistry, 2014, 31 (7), add methylamine and water in the reactor, dissolve, put aluminum dihydrogen tripolyphosphate , stirred and reacted at room temperature, and separated to obtain catalyst A.

preparation example 2

[0032] According to the same method as catalyst preparation example 1, except adding ethylamine instead of methylamine, the others are the same to obtain catalyst B.

preparation example 3

[0034] According to the same method as catalyst preparation example 1, except adding pyridine instead of methylamine and water, the rest are the same to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com