Cathode electrophoresis paint suitable for range hood and preparation method thereof

The technology of cathodic electrophoretic paint and range hood is applied in the field of paint, which can solve the problems of heavy environmental pollution and poor oil resistance, and achieve the effects of high gloss, strong adhesion and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

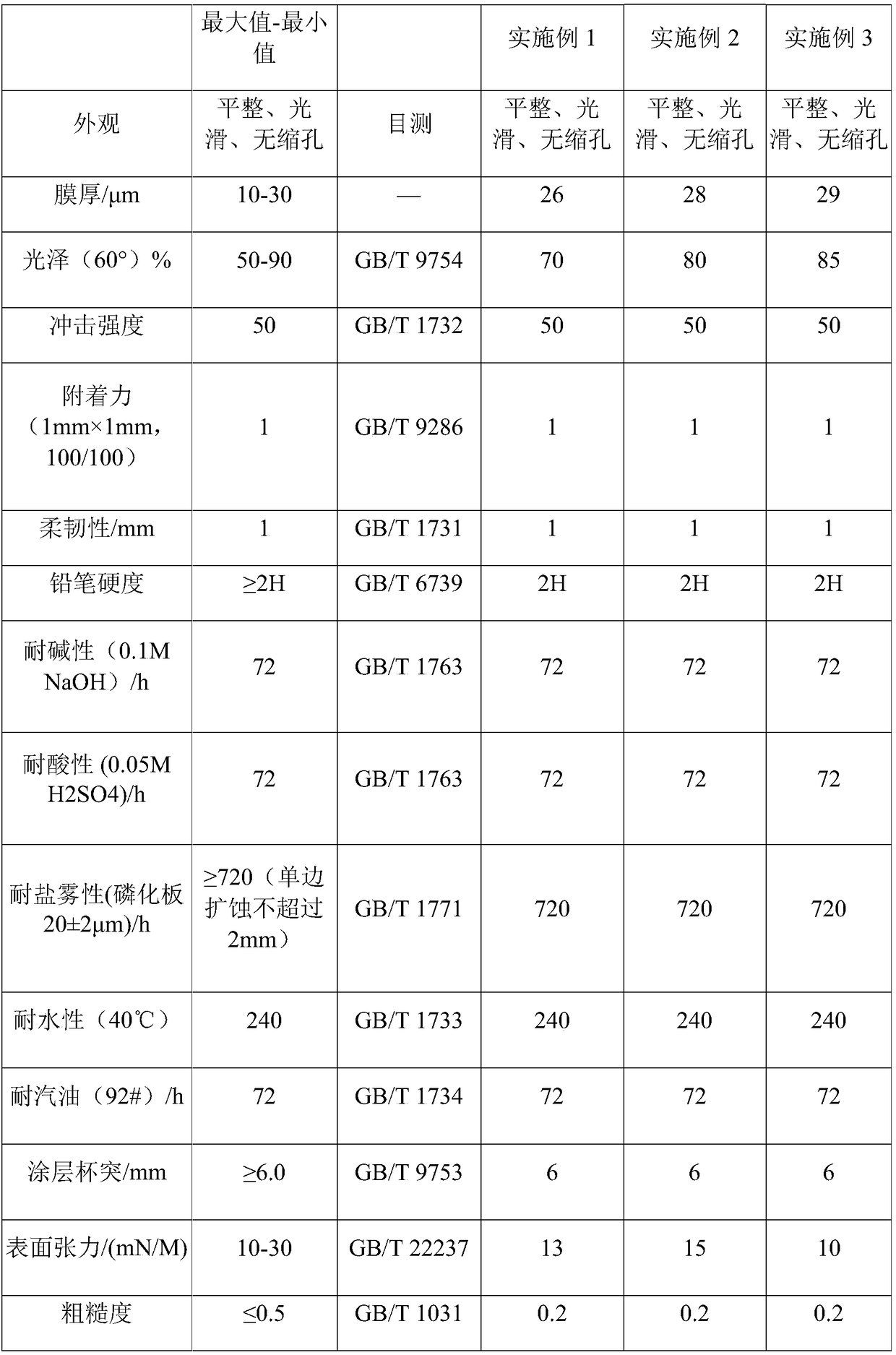

Examples

preparation example Construction

[0029] In one embodiment, the preparation method includes the following steps:

[0030] (1) Take each component according to the raw material ratio of the cathodic electrophoretic coating applicable to range hoods;

[0031] (2) Mixing and grinding the fluorine-modified epoxy resin, environment-friendly solvent, neutralizer, surfactant, kaolin, pigment and pure water to obtain a color paste;

[0032] (3) mixing the fluorine-modified epoxy resin, emulsifier, neutralizer and pure water to obtain an emulsion;

[0033] (4) Mixing the color paste, the emulsion and pure water to obtain a cathodic electrophoretic coating suitable for range hoods.

[0034] The above-mentioned preparation method is further explained below:

[0035] Preferably, in step (4), the stirring speed of the mixing treatment is 500-2500 rpm, and the stirring is sufficient to obtain a uniform cathodic electrophoretic coating.

[0036] Preferably, the grinding fineness of the grinding treatment is ≤10um to ensur...

Embodiment 1

[0040] A cathodic electrophoretic coating suitable for range hoods, comprising the following raw material components in mass fractions: 20% of color paste, 30% of emulsion, and 50% of pure water;

[0041] The color paste includes the following components in parts by mass: 18 parts of fluorine-modified epoxy resin, 5 parts of environmental protection cosolvent, 1 part of neutralizer, 0.4 part of surfactant, 30 parts of pure water, 22.6 parts of kaolin, 9 parts of carbon black;

[0042] The emulsion includes the following components in parts by mass: 40 parts of fluorine-modified epoxy resin, 6 parts of emulsifier, 3 parts of neutralizer, and 50 parts of pure water.

[0043] The cathodic electrophoretic paint preparation method suitable for range hoods comprises the following steps:

[0044] (1) Take each component according to the raw material ratio of the cathodic electrophoretic coating applicable to range hoods;

[0045] (2) Mix the fluorine-modified epoxy resin, environme...

Embodiment 2

[0049] A cathodic electrophoretic coating suitable for range hoods, comprising the following raw material components in mass fractions: 10% of color paste, 40% of emulsion, and 40% of pure water;

[0050] The color paste includes the following components in parts by mass: 30 parts of fluorine-modified epoxy resin, 15 parts of environmental protection cosolvent, 5 parts of neutralizer, 0.5 part of surfactant, 40 parts of pure water, 28 parts of kaolin, 6 parts of carbon black;

[0051] The emulsion includes the following components in parts by mass: 35 parts of fluorine-modified epoxy resin, 4 parts of emulsifier, 6 parts of neutralizer, and 45 parts of pure water.

[0052] The cathodic electrophoretic paint preparation method suitable for range hoods comprises the following steps:

[0053] (1) Take each component according to the raw material ratio of the cathodic electrophoretic coating applicable to range hoods;

[0054] (2) Mix the fluorine-modified epoxy resin, environme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com