Double-component quick-dry wear-resisting waterborne epoxy coating and preparation method thereof

A water-based epoxy coating, two-component technology, applied in the field of coatings, can solve the problems of slow drying speed, poor substrate adhesion, low hardness, etc., and achieve the effect of fast drying speed, good adhesion and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

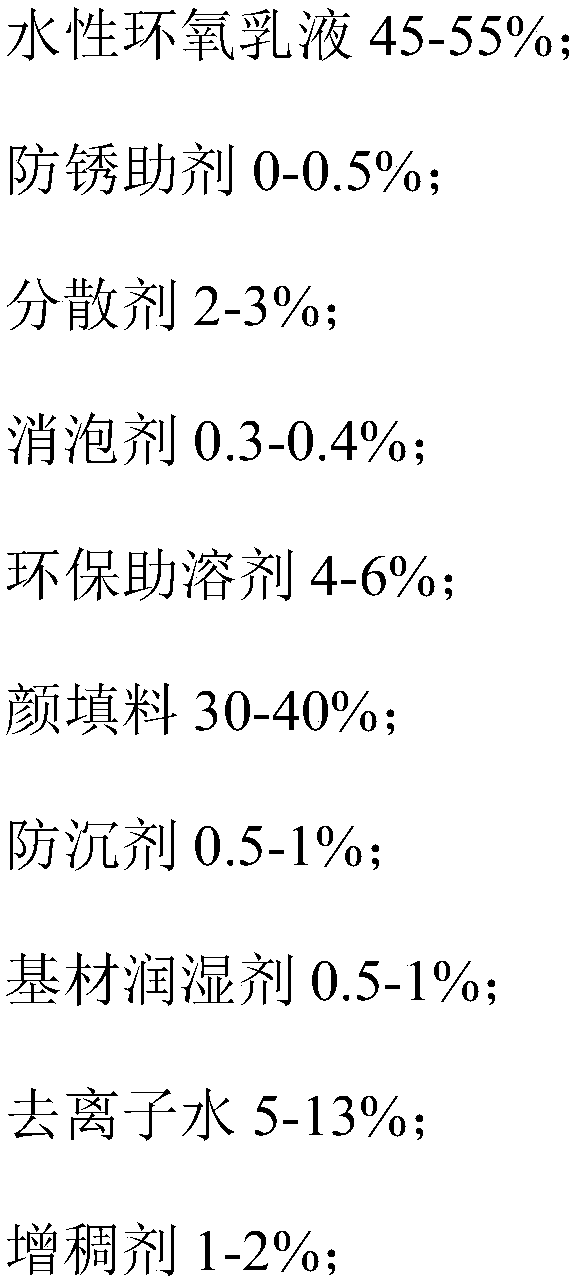

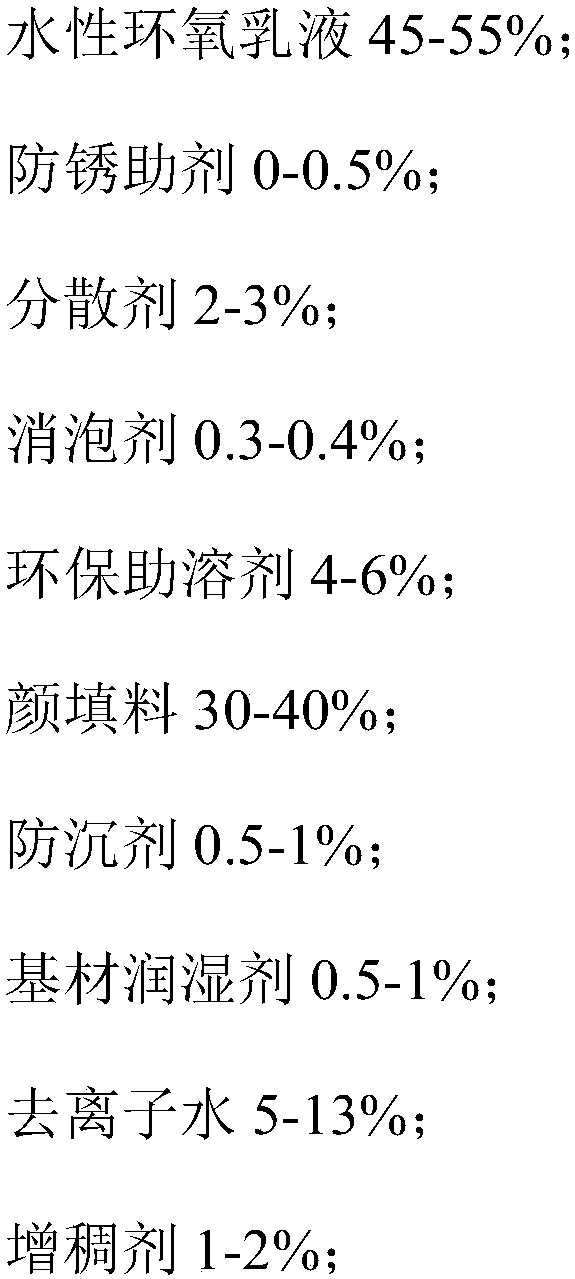

[0038] In one embodiment, the preparation method includes the following steps:

[0039] (1) Weigh each component according to the raw material ratio of the two-component quick-drying and wear-resistant waterborne epoxy coating;

[0040] (2) Mix and grind the 55-65wt% deionized water, defoamer, dispersant, 20wt% environmentally friendly cosolvent, pigments and fillers, and anti-settling agent in the A component to obtain the first Mixed material

[0041] (3) Mixing the remaining deionized water, remaining environmentally friendly cosolvent, and water-based epoxy emulsion in component A to obtain a second mixture;

[0042] (4) After mixing the first mixture material, the second mixture material, the substrate wetting agent, and the anti-rust auxiliary agent, add the thickener and stir to obtain component A;

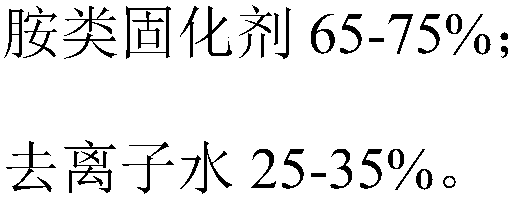

[0043] (5) Mixing the amine curing agent and deionized water in the B component to obtain the B component;

[0044] (6) Mix the components A and B to obtain a two-component quick-dry...

Embodiment 1-5

[0051] The mass fractions of the raw material components of the two-component quick-drying and wear-resistant waterborne epoxy coating in the examples are shown in Table 1:

[0052]

Embodiment 1-3

[0054] The preparation method of the two-component quick-drying wear-resistant waterborne epoxy coating in Examples 1-3 includes the following steps:

[0055] (1) Weigh each component according to the raw material ratio of the two-component quick-drying and wear-resistant waterborne epoxy coating;

[0056] (2) Mix 60wt% deionized water, defoamer, dispersant, 20wt% propylene glycol butyl ether, pigments and anti-settling agents in the A component at 600r / min for 25min, grinding treatment To the fineness ≤20μm, the first mixture material is obtained;

[0057] (3) Mix the remaining deionized water, remaining propylene glycol butyl ether, and water-based epoxy emulsion in component A at 600r / min for 10 minutes to obtain a second mixture;

[0058] (4) After mixing the first mixture material, the second mixture material, the substrate wetting agent, and the anti-rust auxiliary agent at 500r / min for 15 minutes, add the thickener and stir to obtain component A;

[0059] (5) Mixing the amine cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com