Core-shell structure nickel-cobalt-manganese ternary cathode material precursor and preparation method thereof

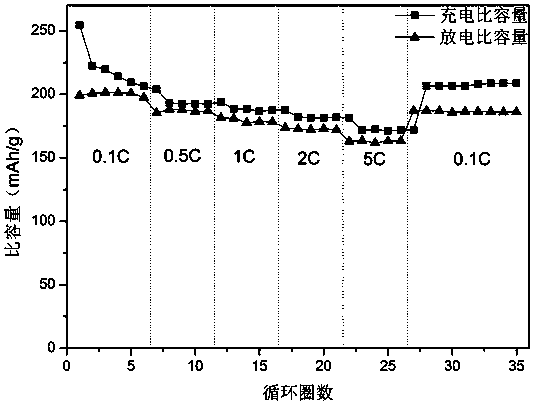

A technology of cathode material and core-shell structure, which is applied in the field of core-shell structure nickel-cobalt-manganese ternary cathode material precursor and its preparation, can solve the problems of cumbersome preparation process, poor rate performance, and low capacity, and achieve simple process and low cost. The effect of low and shortened diffusion channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

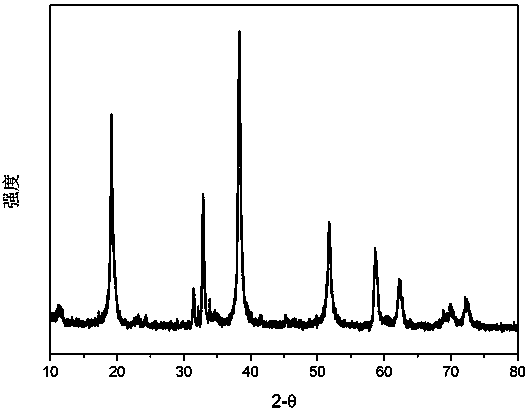

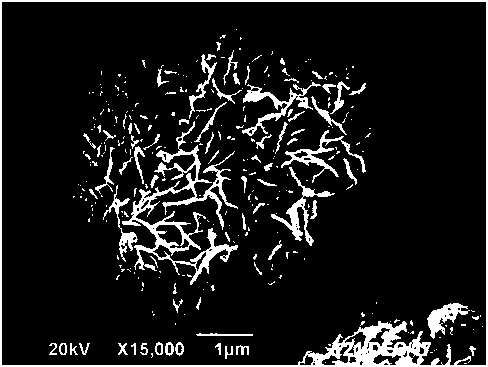

[0054] The precursor of the ternary positive electrode material is a core-shell structure particle with an average particle diameter of 10 μm, wherein the average diameter of the inner core is 8 μm, the average thickness of the shell layer is 2 μm, and the shell layer has micropores with a pore size of 0.2-0.5 μm; wherein, The chemical formula of the core is Ni 0.9 co 0.1 (OH) 2 ; The chemical formula of the shell is Ni 0.7 co 0.1 mn 0.2 CO 3 .

[0055] Example 1 of the preparation method of the precursor of the core-shell structure nickel-cobalt-manganese ternary positive electrode material

[0056] (1) Mix 2L nickel-cobalt solution with high nickel content (a mixed solution of nickel sulfate and cobalt sulfate, wherein the molar percentages of Ni and Co in the total metal ions are 90% and 10% respectively, and the metal ion concentration is 2mol / L) with The feeding rate is 80mL / h, pump into the reaction kettle with 2L ammonia solution with a molar concentration of 0.4...

Embodiment 2

[0066] The precursor of the ternary cathode material is a core-shell structure particle with an average particle diameter of 10 μm, wherein the average diameter of the inner core is 6 μm, the average thickness of the shell layer is 4 μm, and the shell layer has micropores with a pore size of 0.1-0.4 μm; wherein, The chemical formula of the core is Ni 0.8 co 0.1 mn 0.1 (OH) 2 ; The chemical formula of the shell is Ni 0.4 co 0.2 mn 0.4 CO 3 .

[0067] Example 2 of the preparation method of the precursor of the core-shell structure nickel-cobalt-manganese ternary positive electrode material

[0068] (1) Mix 2L nickel-cobalt-manganese solution with high nickel content (a mixed solution of nickel nitrate, cobalt nitrate and manganese nitrate, wherein the molar percentages of Ni, Co, and Mn in the total metal ions are 80%, 10%, and 10%, respectively, The metal ion concentration is 2.5mol / L) at a feed rate of 60mL / h, pump 1.8L of ammonia solution with a molar concentration of...

Embodiment 3

[0078] The precursor of the ternary cathode material is a core-shell structure particle with an average particle diameter of 11 μm, wherein the average diameter of the inner core is 8 μm, the average thickness of the shell layer is 3 μm, and the shell layer has micropores with a pore size of 0.1-0.5 μm; wherein, The chemical formula of the core is Ni 0.85 co 0.15 (OH) 2 ; The chemical formula of the shell is Ni 0.55 co 0.15 mn 0.3 CO 3 .

[0079] Example 3 of the preparation method of the precursor of the core-shell structure nickel-cobalt-manganese ternary positive electrode material

[0080] (1) Mix 2L high-nickel-content nickel-cobalt-manganese solution (a mixed solution of nickel chloride and cobalt chloride, wherein the molar percentages of Ni and Co in the total metal ions are 85% and 15% respectively, and the metal ion concentration is 1.5mol / L) At a feed rate of 100mL / h, pump 2.2L of ammonia solution with a molar concentration of 0.40mol / L into a 5L reaction ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com