Coated lithium ion battery high-nickel positive electrode material and preparation method thereof

A lithium-ion battery and cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of non-primary particle interface coating, impedance rise, effect discount, etc., to eliminate residual alkali substances and suppress high-temperature gas production. , the effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

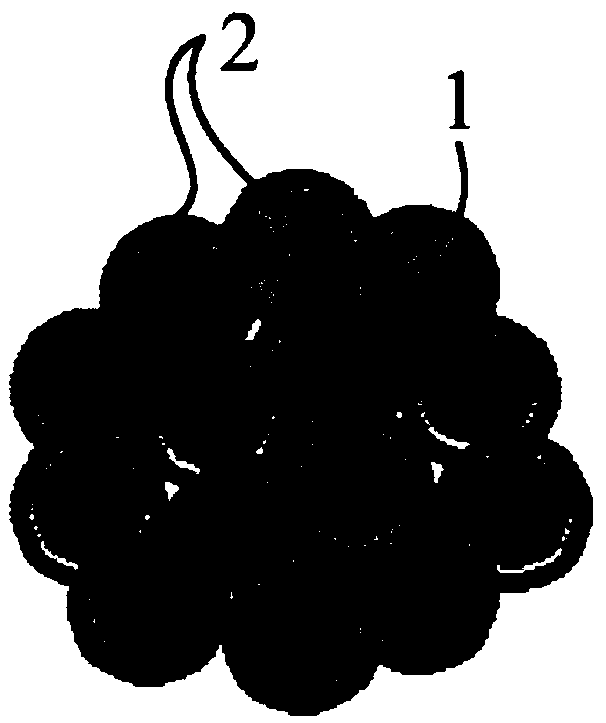

[0032] Such as figure 1 As shown, the preparation method of a kind of coated lithium ion battery high-nickel positive electrode material provided by the invention: the LiNi of 100g 0.88 co 0.09 Al 0.03 o 2 Carry out mechanical fine grinding and dissociate into a primary particle structure, weigh 4.55g of aluminum isopropoxide, add 450mL of isopropanol for ultrasonic dissolution, and add the dissociated LiNi under stirring 0.88 co 0.09 Al 0.03 o 2 , after reacting for 1 hour, enter closed cycle spray drying, set the temperature of air inlet and air outlet to 250°C and 100°C respectively, recover isopropanol, and at the same time, LiNi 0.88 co 0.09 Al 0.03 o 2 Granulation to re-form secondary particles; the collected precursor was sintered at 500°C for 3h in an oxygen-rich atmosphere to obtain 1.5wt% LiAlO 2 Coated LiNi 0.88 co 0.09 Al 0.03 o 2 .

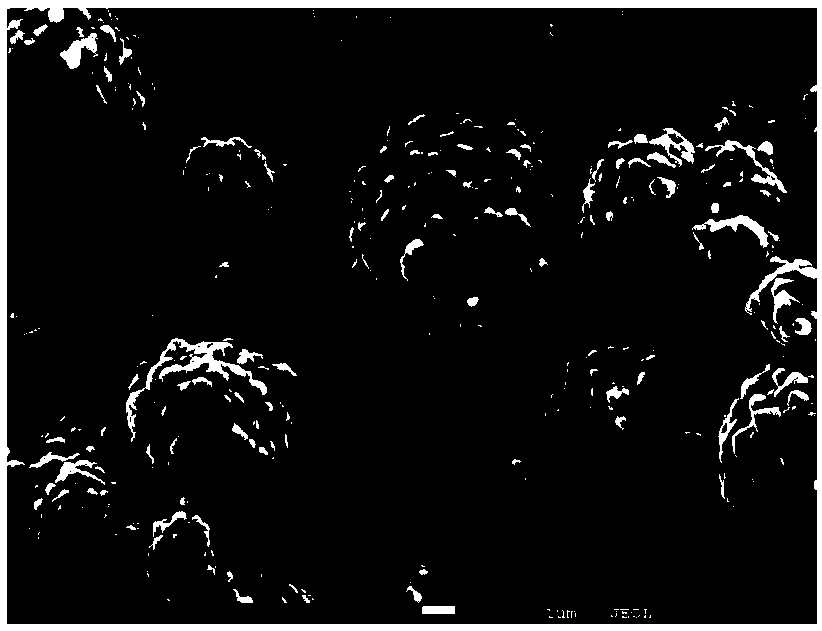

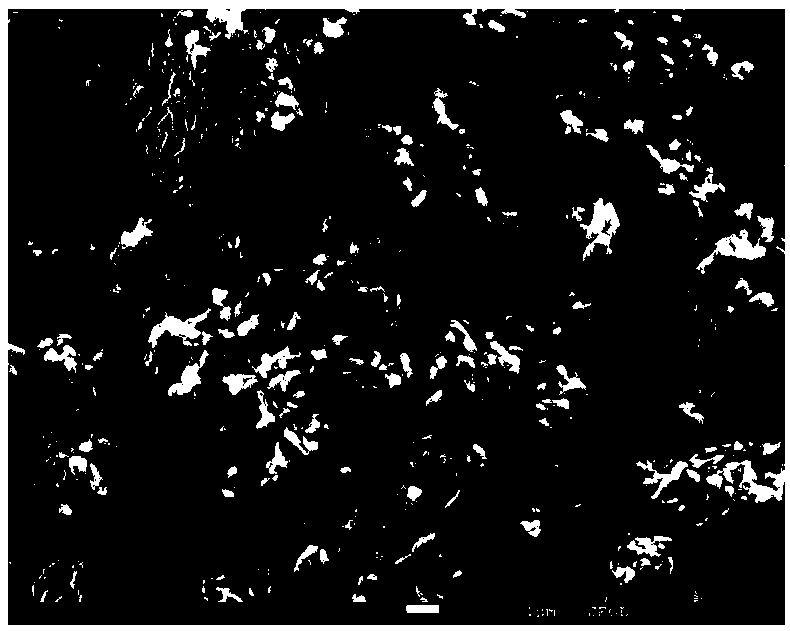

[0033] From figure 2 , 3 From the comparative SEM images shown, LiNi 0.88 co 0.09 Al 0.03 o 2After mechanical ...

Embodiment 2

[0037] In the present embodiment, the LiNi of 100g 0.8 co 0.1 Ti 0.1 o 2 Carry out mechanical fine grinding and dissociate into a primary particle structure, weigh 3.1g tetrabutyl titanate and 2.1g zirconium isopropoxide, add 200mL n-propanol and 300mL n-butanol to ultrasonically dissolve, add the dissociated LiNi under stirring 0.8 co 0.1 Ti 0.1 o 2 , after reacting for 2 hours, it enters the closed cycle spray drying, recovers the organic solvent, and sinters the collected precursor at 700 °C for 1 hour under an oxygen atmosphere to obtain 1wt% Li 2 TiO 3 and 1 wt% Li 2 TiO 3 Coated LiNi 0.8 co 0.1 Ti 0.1 o 2 .

Embodiment 3

[0039] In the present embodiment, the LiNi of 100g 0.6 co 0.2 mn 0.2 o 2 Carry out mechanical fine grinding and dissociate into a primary particle structure, weigh 0.31g of aluminum isopropoxide, add 100mL of ethanol for ultrasonic dissolution, and add the dissociated LiNi under stirring 0.6 co 0.2 mn 0.2 o 2 , after reacting for 3 hours, it enters the closed cycle spray drying, recovers the organic solvent, and sinters the collected precursor at 400 °C for 6 hours under an oxygen atmosphere to obtain 0.1wt% LiAlO 2 Coated LiNi 0.6 co 0.2 mn 0.2 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com