Preparation and application of block polymer electrolyte

A block polymer and electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of affecting lithium ion transmission, low electrochemical stability window, etc., achieve shape diversification, improve interface performance, The effect of small product shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

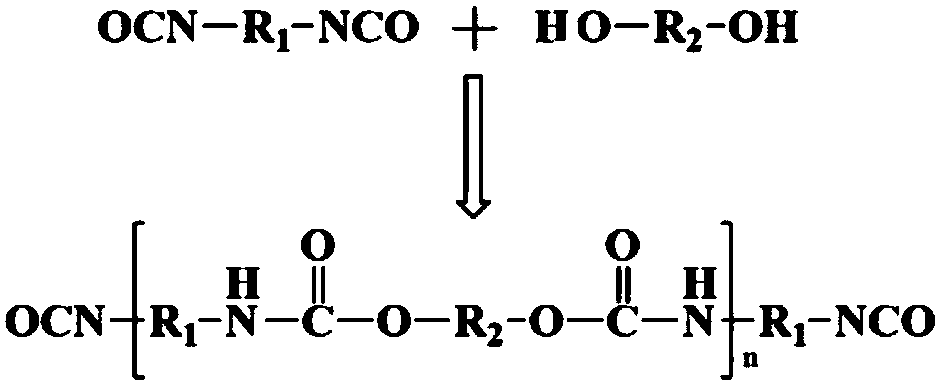

[0028] According to the ratio of R to 1.2, mix and stir 1mmol HDI trimer, 1.25mmol PEG (Mw=800), 4ml acetonitrile and tetraethylene glycol dimethyl ether (TEGDME) (V:V=1:1); add 1g lithium hexafluorophosphate (LiPF 6 ) were mixed evenly to prepare a transparent and clear electrolyte; 0.1 g of dibutyltin dilaurate was added dropwise and stirred evenly; the evenly stirred composite polymer electrolyte was scraped onto a polytetrafluoroethylene mold, and heated to 60°C in a glove box, Cured for 12 hours to form a film.

Embodiment 2

[0030] According to the ratio of R to 0.8, mix 1mmol HDI trimer, 1.875mmol PEG (Mw=1500), 4ml tetraethylene glycol dimethyl ether (TEGDME) and 1-methyl-2 pyrrolidone (V:V=1:1) Mix and stir; add 2g LiN(C 2 f 5 SO 2 ) 2 Mix evenly to prepare a transparent and clear electrolyte; add 0.15g of dibutyltin dilaurate dropwise and stir evenly; scrape the evenly stirred composite polymer electrolyte onto a polytetrafluoroethylene mold, heat it to 60°C in a glove box, and cure 12 hours film formation.

Embodiment 3

[0032] According to the ratio of R to 1, mix and stir 1mmol HDI, 1mmol EG and 4ml tetraethylene glycol dimethyl ether evenly; add 2g LiBOB and mix evenly to prepare a transparent and clear electrolyte; dropwise add 0.08g bis(acetylacetonate) dibutyltin Stir evenly; scrape-coat the evenly stirred composite polymer electrolyte onto a polytetrafluoroethylene mold, heat to 60°C in a glove box, and cure for 12 hours to form a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com