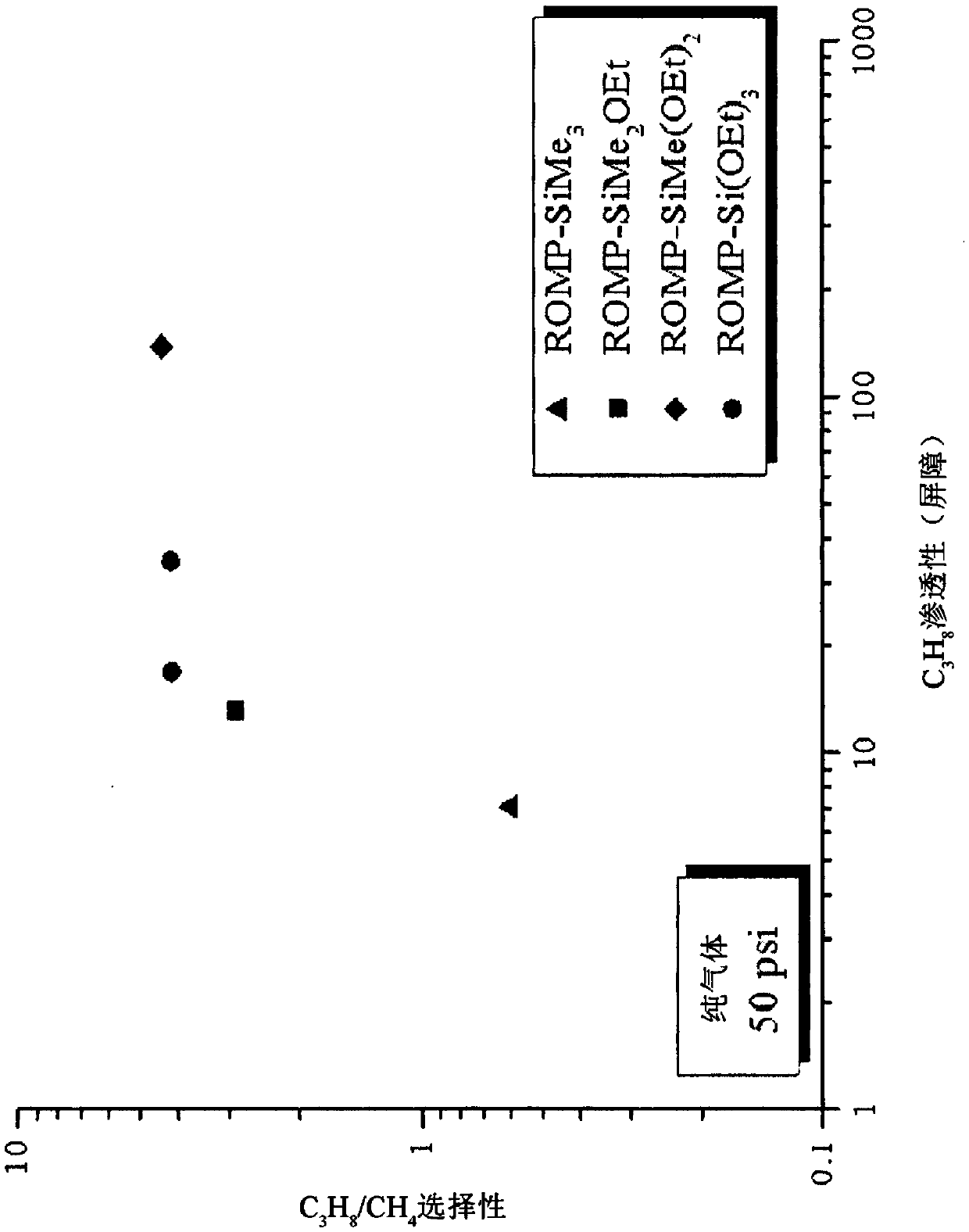

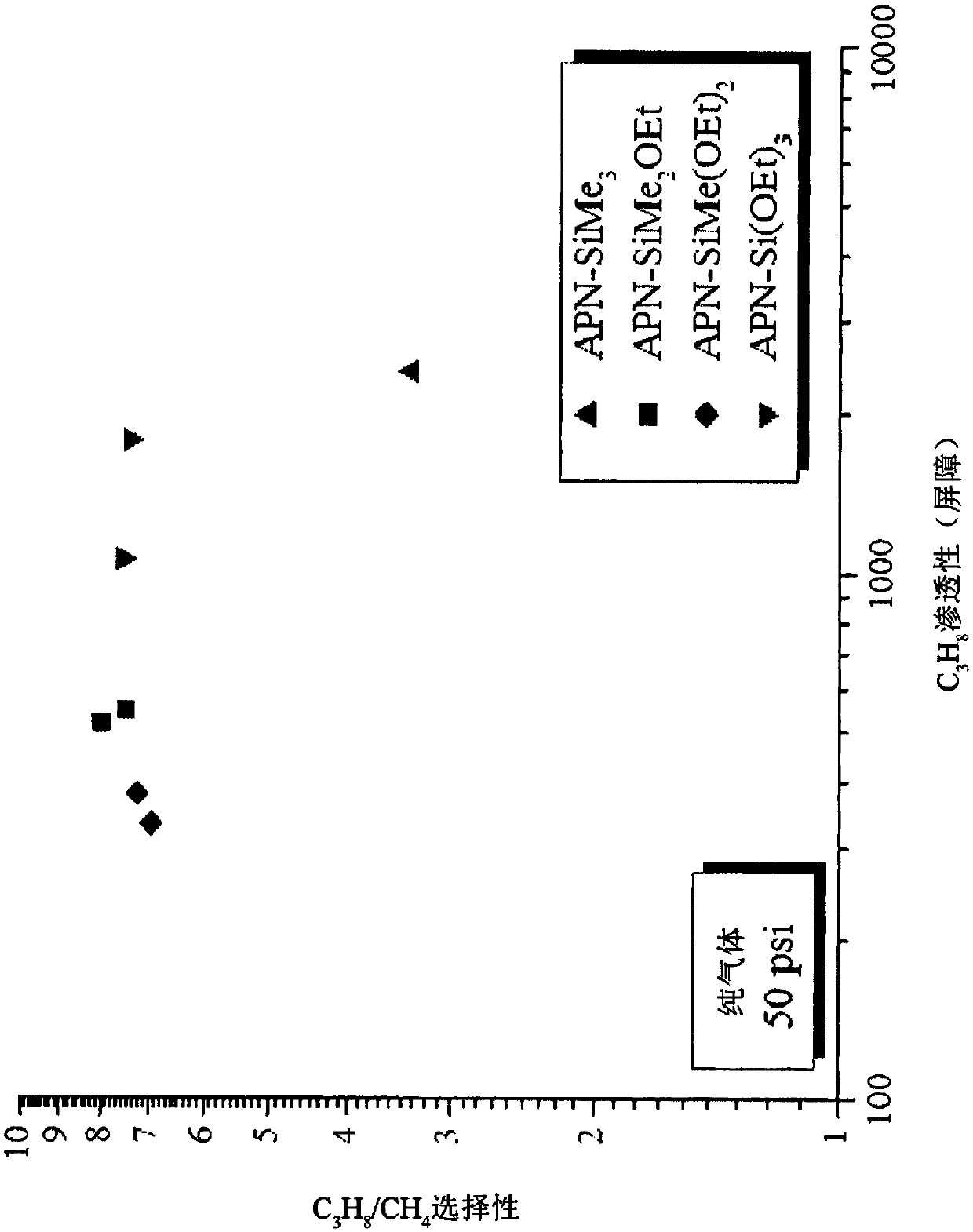

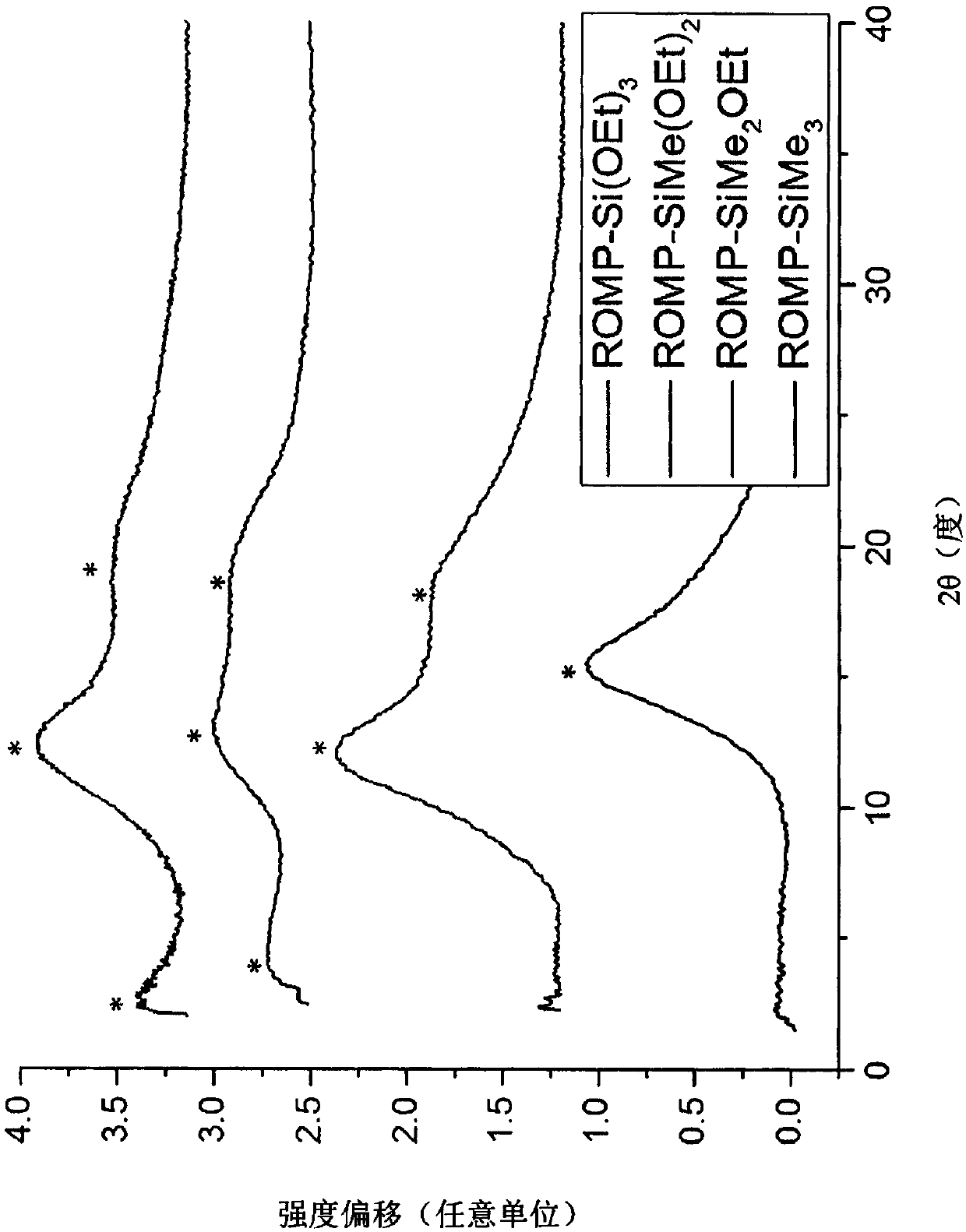

Highly selective polynorbornene homopolymer membranes for natural gas upgrading

A technology of polynorbornene and norbornene, which is applied in the direction of climate sustainability, membrane, membrane technology, etc., and can solve problems such as low selectivity, performance decline, and permeability reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0059] Ring-opening metathesis polymerization of triethoxysilylnorbornene (ROMP-Si(OEt) 3 )synthesis:

[0060] To illustrate with reference to Reaction 1, in a glove box, 03.85 g of as received triethoxysilylnorbornene (0.05 molar (M), 1.51 mmol (mmol) )) and 29 mL of anhydrous deoxygenated toluene. In a separate vial, 2.5 milligrams (mg) of Grubbs first generation catalyst containing ruthenium (0.003 mmol) was dissolved in 2 mL of anhydrous toluene to create a stock catalyst solution. Finally, 1.0 mL of the catalyst solution was added to the stirred norbornene solution to initiate polymerization. After 24 hours, ethyl vinyl ether (0.431 mL, 4.51 mmol) was added to terminate the polymerization, and the solution was continued to stir. After an additional 24 hours, the solvent was removed under vacuum in the glove box until the sample volume was approximately 5 mL, at which point the sample became a viscous liquid. The viscous solution was precipitated dropwise into stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com