Polyimide film and manufacturing method thereof

A technology of polyimide film and manufacturing method, which is applied to flat products, other household appliances, coatings, etc., which can solve the problems of planarity deterioration, haze deviation, and easy increase of film haze, so as to achieve easy orientation and deviation Small size and good transportability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

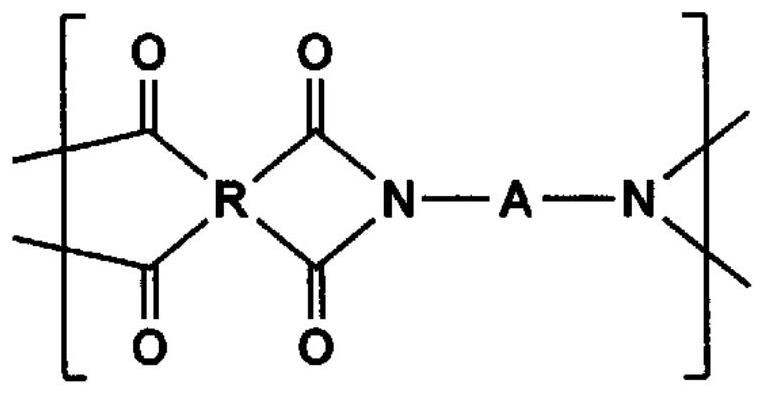

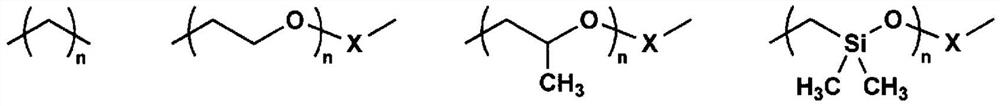

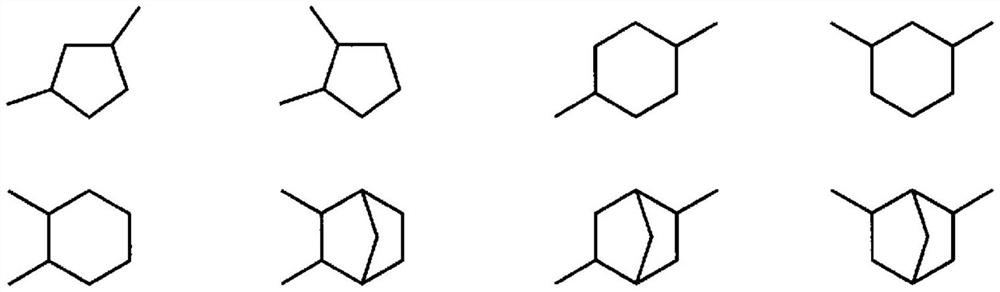

[0461] The structures of the compounds used in the examples are listed below.

[0462] [chem 22]

[0463]

[0464] Anhydride A: Bicyclo[4.2.0]octane-3,4,7,8-tetracarboxylic dianhydride

[0465] Diamine compound B: 2,2′-dimethylbiphenyl-4,4′-diamine

[0466] In addition, the commercially available sources of the above-mentioned compounds are as follows.

[0467] Anhydride 1: Daikin Industries, Ltd.

[0468] Anhydride 2: Manac Co., Ltd.

[0469] Anhydride 3: Daicel Co., Ltd.

[0470] Diamine 1: Daikin Industries, Ltd.

[0471] Diamine 2: Mitsui Chemicals Fine Co., Ltd.

[0472] Diamine 6: Wakayama Seika Co., Ltd.

[0473] Diamine compound B: Showa Chemical Co., Ltd.

[0474]

[0475] (Preparation of polyimide solution A)

[0476] In a 4-neck flask equipped with a dry nitrogen introduction tube, a cooler, a Dean-Stark condenser filled with toluene, and a stirrer, 17.87 g (57.6 mmol) of the above-mentioned acid anhydride 2 (manufactured by Manac Co., Ltd.) was added ...

Embodiment 2

[0566] About the polyimide film 101 and the polyimide film 109 of Example 1, bending resistance was evaluated as follows.

[0567] (bending resistance)

[0568] The produced polyimide film was subjected to a bending resistance test (sliding bending test) using a bending fatigue tester prescribed in JIS C5016. In addition, under the conditions of a bending radius of 2.5mm, a bending speed of 2000 times / min, and a bending stroke of 25mm, bending was repeated in one direction so that the wiring formation surface was turned outward during bending, and the value was obtained until it was positioned outside the bending direction. The number of bending times (bending resistance) of the wiring breakage.

[0569] ◎: more than 5000 times

[0570] ○: More than 1000 times and less than 5000 times

[0571] ×: Less than 1000 times

[0572] Table 3 shows the evaluation results of bending resistance.

[0573]

[0574] As shown in Table 3, it turned out that the polyimide film of this ...

Embodiment 3

[0576] In the preparation of the main dope in the production of the polyimide film 101 of Example 1, except that the following mixing dope 301A was added instead of the crushed product 101A so as to become the mixture mass ratio shown in Table 4, The polyimide film 301 similar to the polyimide film 101 was produced.

[0577] (Preparation of mixing glue 301A)

[0578] (Preparation of polyimide solution 301A)

[0579] In a 4-neck flask equipped with a dry nitrogen introduction tube, a cooler, a Dean-Stark condenser filled with toluene, and a stirrer, 17.87 g (57.6 mmol) of the above-mentioned acid anhydride 2 (manufactured by Manac Co., Ltd.) was added to N,N-2 Methylacetamide (134 g) was stirred at room temperature under a nitrogen stream.

[0580] 11.53 g (60 mmol) of the above-mentioned diamine 2 (manufactured by Mitsui Chemicals Fine Co., Ltd.) was added thereto, and it heated and stirred at 80 degreeC for 6 hours. Then, the external temperature was heated to 190° C., and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com