A method for synthesizing tri-n-butyl citrate with acid-modified h-zms-5 type molecular sieve

A technology of H-ZMS-5 and tri-n-butyl ester, which is applied in the direction of molecular sieve catalysts, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of unsatisfactory catalytic effect of molecular sieves, difficult treatment of reaction waste liquid, and high production costs. , to achieve high yield, reduce the amount of acid, and reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023]In this example, the H-ZMS-5 molecular sieve was modified by sulfuric acid of 5 groups of different concentrations set in Table 1, and then used to catalyze the esterification reaction to prepare tri-n-butyl citrate, to study the effect of different sulfuric acid concentrations on the esterification rate influences.

[0024]The synthesis steps of tri-n-butyl citrate are as follows: H-ZMS-5 molecular sieve (silica-aluminum ratio 25) is dried in a blast drying oven at 300°C for 2 hours to activate it, and the activated H-ZMS-5 molecular sieve is activated with different concentrations of sulfuric acid Soak for 15h (see Table 1 for sulfuric acid concentration), then put it in a blast drying box for drying for two hours, then grind into powder to obtain acid-modified H-ZMS-5 molecular sieve; add 0.538g anhydrous citric acid, 1.24g n-butyl The acid-modified H-ZMS-5 molecular sieve containing 3% alcohol and anhydrous citric acid by mass was added to a 50ml round bottom flask (the molar...

Embodiment 2

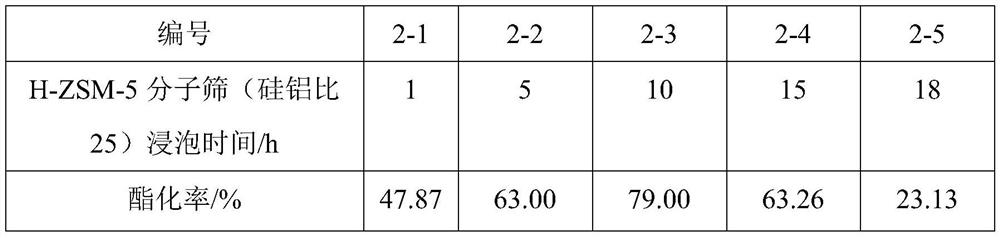

[0028]In this example, the H-ZMS-5 molecular sieve was modified according to the 5 groups of different sulfuric acid soaking times set in Table 2, and then used to catalyze the esterification reaction to prepare tri-n-butyl citrate, and the effect of different sulfuric acid soaking time on esterification was studied. Rate of impact.

[0029]The synthesis steps of tri-n-butyl citrate are as follows: H-ZMS-5 molecular sieve (silica-aluminum ratio 25) is dried in a blast drying oven at 300°C for 2 hours to activate it, and the activated H-ZMS-5 molecular sieve uses 5mol / L Soak in sulfuric acid (see Table 2 for soaking time), then put it in a blast drying box for drying for two hours, and then grind into powder to obtain acid-modified H-ZMS-5 molecular sieve; change anhydrous citric acid, n-butanol, and acid H-ZMS-5 molecular sieve was added to a 50ml round-bottom flask (the molar ratio of anhydrous citric acid and n-butanol was 1:6, and the acid-modified H-ZMS-5 molecular sieve was 3% of ...

Embodiment 3

[0033]In this example, according to the 5 groups of different catalyst addition amounts set in Table 3, the esterification reaction was used to prepare tri-n-butyl citrate, and the effect of different catalyst addition amounts on the esterification rate was studied.

[0034]The synthesis steps of tri-n-butyl citrate are as follows: H-ZMS-5 molecular sieve (silica-aluminum ratio 25) is dried in a blast drying oven at 300°C for 2 hours to activate it, and the activated H-ZMS-5 molecular sieve uses 5mol / L Soak in sulfuric acid for 15 hours, then put it in a blast drying box for drying for two hours, and then grind into powder to obtain acid-modified H-ZMS-5 molecular sieve; anhydrous citric acid, n-butanol, acid-modified H-ZMS-5 The molecular sieve was added to a 50ml round-bottom flask (the molar ratio of anhydrous citric acid to n-butanol was 1:6, and the amount of acid-modified H-ZMS-5 molecular sieve added was shown in Table 3), and the esterification reaction was carried out (the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com