A kind of breakdown-resistant insulating composite material and preparation method thereof

An insulating composite material and anti-puncture technology, which is applied in the field of anti-puncture insulating composite materials and its preparation, can solve the problems of not meeting the needs of electrical products, weak corrosion resistance, and short service life, etc., to increase aging resistance, Ultra-high mechanical properties and improved flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

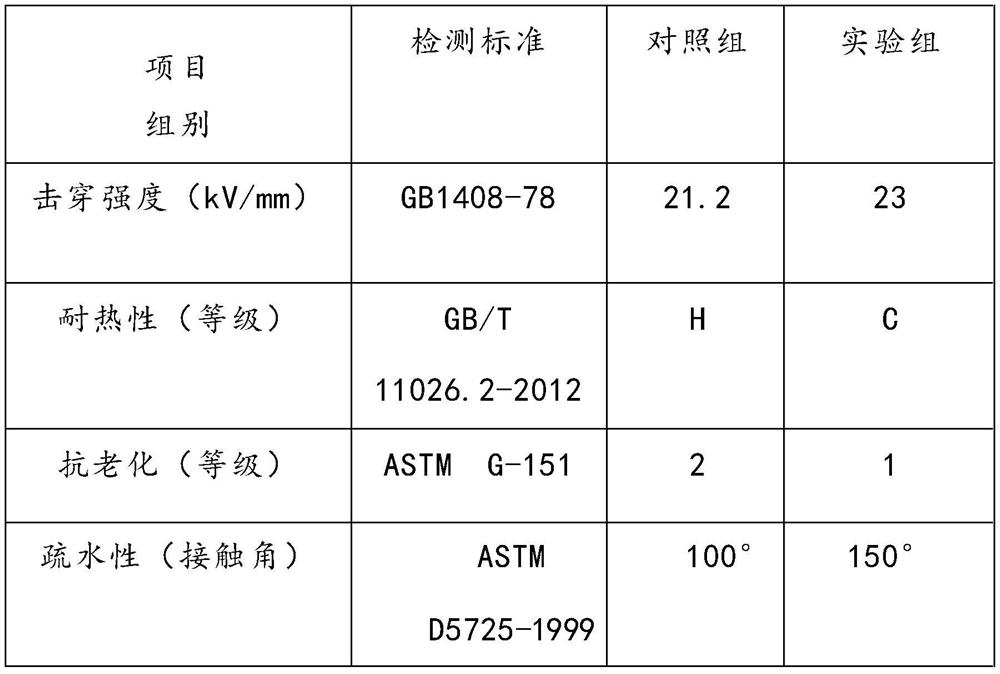

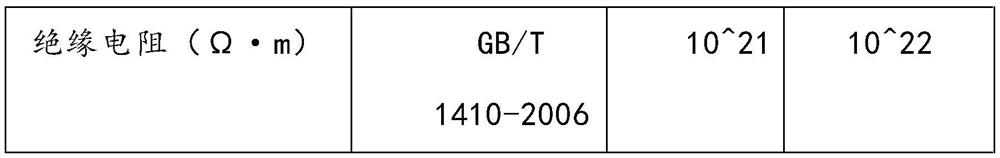

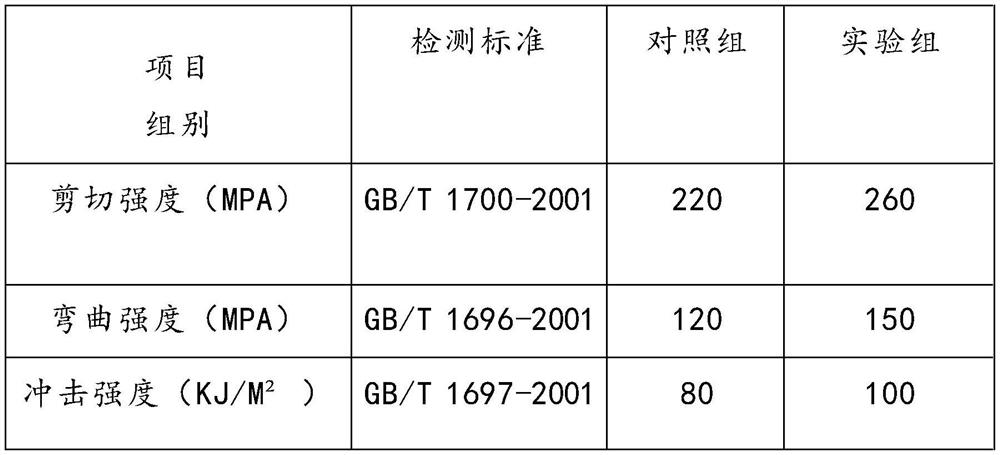

Examples

Embodiment 1

[0012] A breakdown-resistant insulating composite material, which is made of the following materials in proportion by weight: 30 parts of unsaturated polyester resin, 18 parts of polyimide resin, 16 parts of silicone insulating resin, 10 parts of sericite, and naphthalene heterocycle 10 parts of resin, 8 parts of polyethylene terephthalate, 8 parts of polyethylene, 8 parts of butadiene rubber, 8 parts of unsaturated polyester, 8 parts of polyorganosiloxane resin, 6 parts of titanate, double 6 parts of sulfide, 6 parts of phosphite, 6 parts of triallyl phosphate and 6 parts of dicyandiamide.

[0013] A preparation method of anti-puncture insulating composite material, comprising the following steps:

[0014] 1) Take 30 parts of unsaturated polyester resin, 18 parts of polyimide resin, 16 parts of silicone insulating resin and 10 parts of sericite, put them into the mixer and mix them. The stirring speed is 80rpm and the time is 8min. Then put it into the container and heat it ...

Embodiment 2

[0023] A breakdown-resistant insulating composite material, made of the following materials in proportion by weight: 26 parts of unsaturated polyester resin, 26 parts of polyimide resin, 20 parts of silicone insulating resin, 18 parts of sericite, naphthalene heterocycle 16 parts of resin, 12 parts of polyethylene terephthalate, 10 parts of polyethylene, 10 parts of butadiene rubber, 10 parts of unsaturated polyester, 10 parts of polyorganosiloxane resin, 8 parts of titanate, double 8 parts of sulfide, 8 parts of phosphite, 8 parts of triallyl phosphate and 8 parts of dicyandiamide.

[0024] A preparation method of anti-puncture insulating composite material, comprising the following steps:

[0025] 1) Take 26 parts of unsaturated polyester resin, 26 parts of polyimide resin, 20 parts of silicone insulating resin and 18 parts of sericite, put them into a mixer and mix them at a speed of 50 rpm for 6 minutes. Then put it into the container and heat it in a water bath at a temp...

Embodiment 3

[0034] A breakdown-resistant insulating composite material, made of the following materials in proportion by weight: 28 parts of unsaturated polyester resin, 22 parts of polyimide resin, 18 parts of silicone insulating resin, 14 parts of sericite, naphthalene heterocycle 13 parts of resin, 10 parts of polyethylene terephthalate, 9 parts of polyethylene, 9 parts of butadiene rubber, 9 parts of unsaturated polyester, 9 parts of polyorganosiloxane resin, 7 parts of titanate, double 7 parts of sulfide, 7 parts of phosphite, 7 parts of triallyl phosphate and 7 parts of dicyandiamide.

[0035] A preparation method of anti-puncture insulating composite material, comprising the following steps:

[0036] 1) Take 28 parts of unsaturated polyester resin, 22 parts of polyimide resin, 18 parts of silicone insulating resin and 14 parts of sericite, put them into a mixer and mix them. The stirring speed is 65rpm and the time is 7min. Then put it into the container and heat it in a water bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com