Photo-thermal low-temperature anti-icing pasting pad

An anti-icing, photothermal technology, applied in the fiber type, filament/wire forming, film/flake adhesive, etc., can solve the problem of failure, high energy consumption for heating and deicing, and reduced heat transfer efficiency of equipment, etc. problem, to achieve the effect of good thermal insulation, reduction of icing speed, and anti-icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

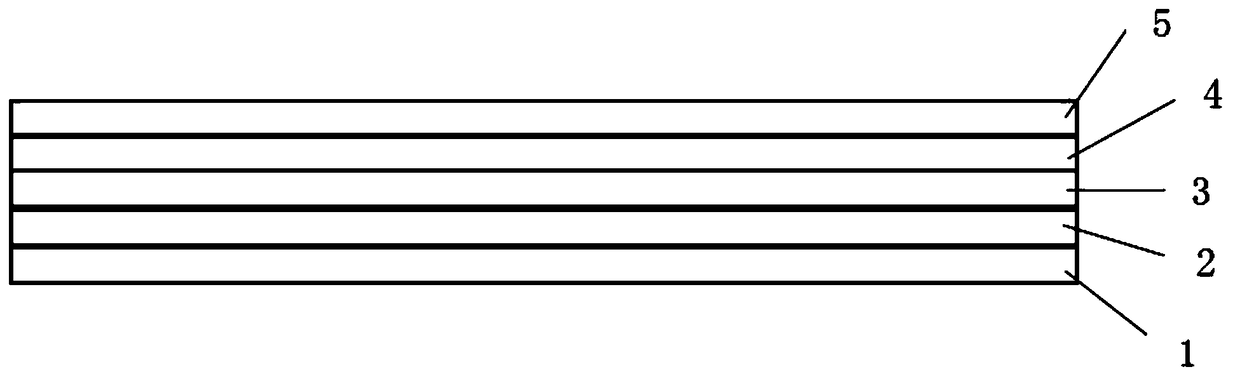

[0036] In this embodiment, a photothermal type low-temperature anti-icing film includes a functional film layer and an adhesive layer, and the functional film layer includes a base film, a photothermal layer, a self-repairing super-hydrophobic layer, a silver nanowire layer, and a base film A photothermal layer is arranged on the photothermal layer, a self-repairing superhydrophobic layer is arranged on the photothermal layer, and a silver nanowire layer is arranged on the self-repairing superhydrophobic layer; the adhesive layer is a transparent acrylate adhesive; the self-repairing superhydrophobic layer The hydrophobic layer is polyacrylate-polysiloxane-stearylamine-silica superhydrophobic coating,

[0037] The preparation of functional film layer comprises the following steps:

[0038] S1. High-voltage electrospinning basement membrane

[0039] Dissolve polyvinylidene fluoride in tetrahydrofuran, with a mass percentage of 12%, and stir to obtain a high-voltage electrospin...

Embodiment 2

[0051] In this embodiment, a photothermal type low-temperature anti-icing film includes a functional film layer and an adhesive layer, and the functional film layer includes a base film, a photothermal layer, a self-repairing super-hydrophobic layer, a silver nanowire layer, and a base film A photothermal layer is arranged on the photothermal layer, a self-repairing superhydrophobic layer is arranged on the photothermal layer, and a silver nanowire layer is arranged on the self-repairing superhydrophobic layer; the adhesive layer is a transparent acrylate adhesive; the self-repairing superhydrophobic layer The hydrophobic layer is polyacrylate-polysiloxane-stearylamine-silicon dioxide superhydrophobic coating;

[0052] The preparation of functional film layer comprises the following steps:

[0053] S1. High-voltage electrospinning basement membrane

[0054] Dissolve polytetrafluoroethylene in tetrahydrofuran, with a mass percentage of 12%, and stir to obtain a high-voltage el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com