Preparation method of manganese dioxide and application

A technology of manganese dioxide and oxidant, which is applied in the field of lithium-ion batteries, can solve problems such as the instability of the positive electrode modified material structure, achieve good stability and cycle performance, improve stability, and reduce the effect of contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

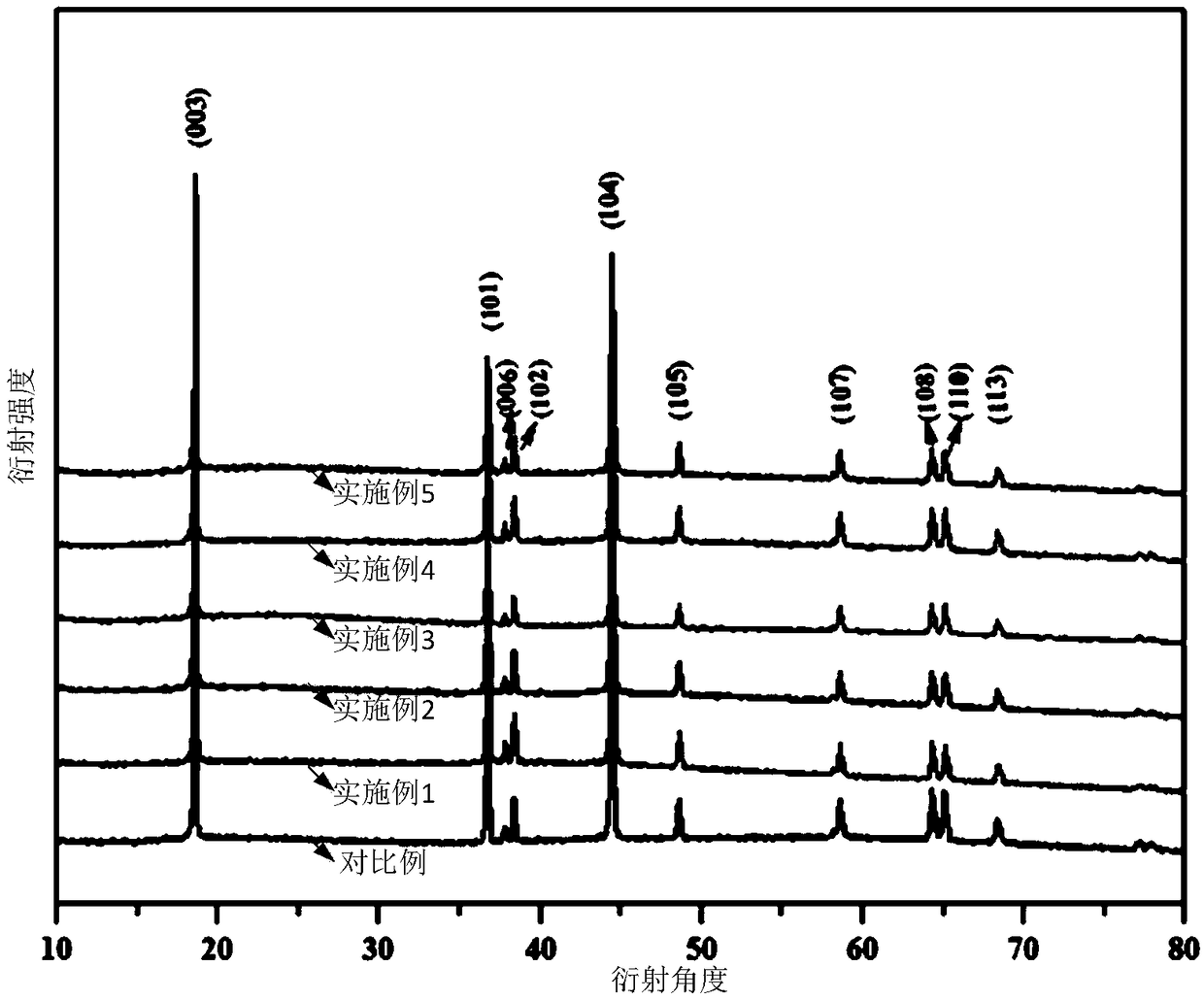

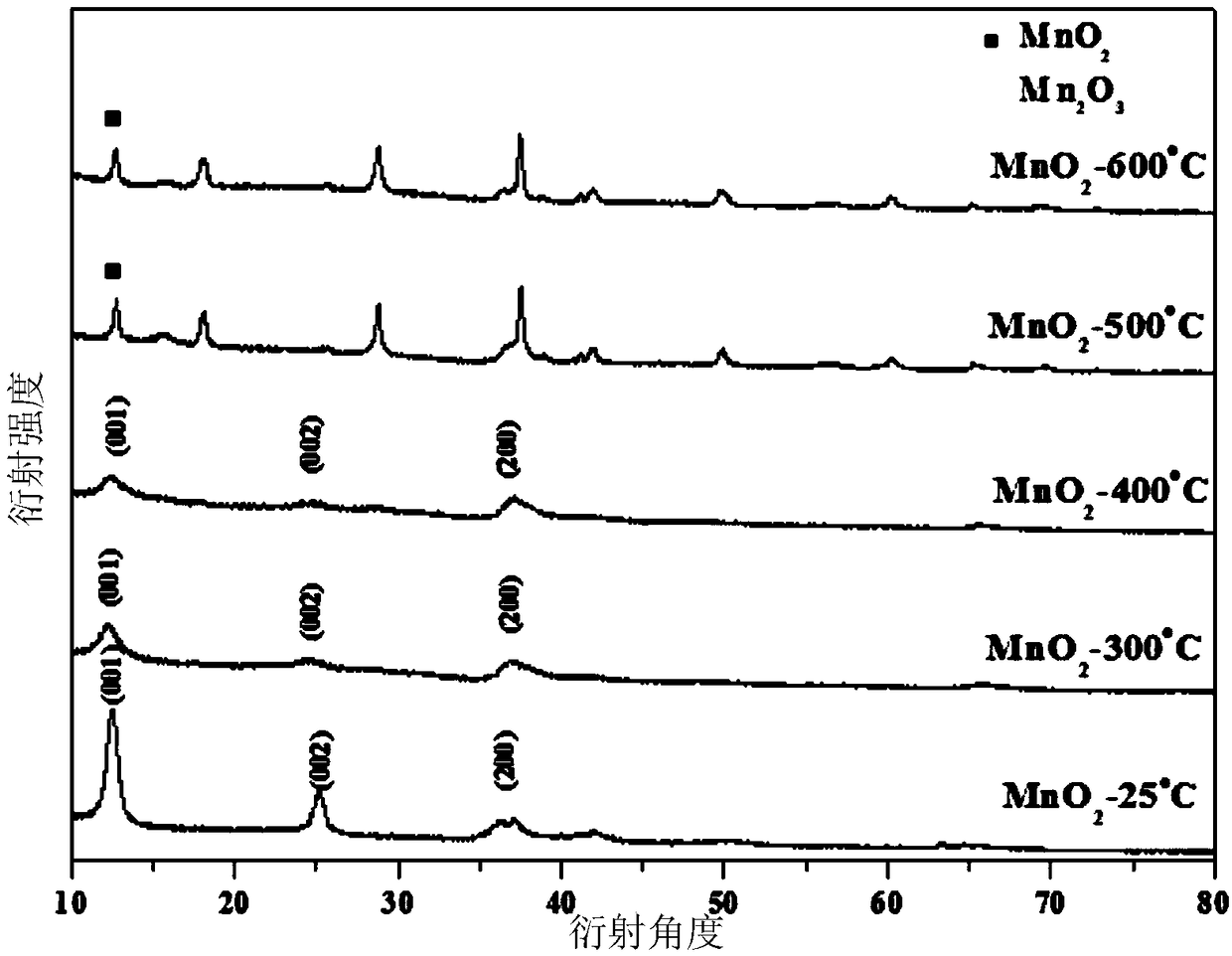

Embodiment 1

[0063] (1) Weigh an appropriate amount of pure phase ternary lithium-ion battery cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , added to deionized water, and ultrasonically oscillated until the pure-phase ternary material is uniformly dispersed; adding 0.49 g of manganese acetate to the dispersion, and ultrasonically oscillated until the manganese acetate is completely dissolved to obtain the first mixed solution;

[0064] (2) Add 4.47g hydroxyethylenediamine tetraacetic acid to the first mixed solution, and ultrasonically vibrate until the complexing agent is completely dissolved to obtain the second mixed solution;

[0065] (3) Add an appropriate amount of sodium dodecylsulfonate to the second mixed solution, and ultrasonically vibrate until it is completely dissolved to obtain a third mixed solution. to stir;

[0066] (4) Weigh an appropriate amount of potassium hydroxide and potassium persulfate respectively, add them to deionized water, and dissolve; add the two to the...

Embodiment 2

[0069] (1) Weigh an appropriate amount of pure phase ternary lithium-ion battery cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , added to deionized water, and ultrasonically oscillated until the pure-phase ternary material is uniformly dispersed; adding 0.98 g of manganese acetate to the dispersion, and ultrasonically oscillated until the manganese acetate is completely dissolved to obtain the first mixed solution;

[0070] (2) Add 4.47g of diethylenetriaminepentaacetic acid to the first mixed solution, and ultrasonically vibrate until the complexing agent is completely dissolved to obtain a second mixed solution;

[0071] (3) Add an appropriate amount of α-olefin sulfonate to the second mixed solution, and ultrasonically vibrate until it is completely dissolved to obtain a third mixed solution, and carry out the process on the third mixed solution under the condition that the temperature of the water bath is 35° C. stir;

[0072] (4) Weigh an appropriate amount of sodium hy...

Embodiment 3

[0075] (1) Weigh an appropriate amount of pure phase ternary lithium-ion battery cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , added to deionized water, and ultrasonically oscillated until the pure-phase ternary material is uniformly dispersed; adding 0.49 g of manganese acetate to the dispersion, and ultrasonically oscillated until the manganese acetate is completely dissolved to obtain the first mixed solution;

[0076] (2) Add 1.49g ethylenediaminetetraacetic acid (EDTA) to the first mixed solution, and ultrasonically vibrate until the complexing agent is completely dissolved to obtain a second mixed solution;

[0077] (3) Add an appropriate amount of sodium lauryl sulfate to the second mixed solution, ultrasonically vibrate until it is completely dissolved to obtain a third mixed solution, and carry out stir;

[0078] (4) Weigh an appropriate amount of sodium hydroxide and potassium persulfate respectively, add them to deionized water, and dissolve; add the two to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com