Method for preparing pleurotus ostreatus culture material

The technology of culture material and oyster mushroom is applied in the field of culture material, which can solve the problems of inconvenient collection and wide dispersion, and achieve the effects of good economic benefit, low cost and simple material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

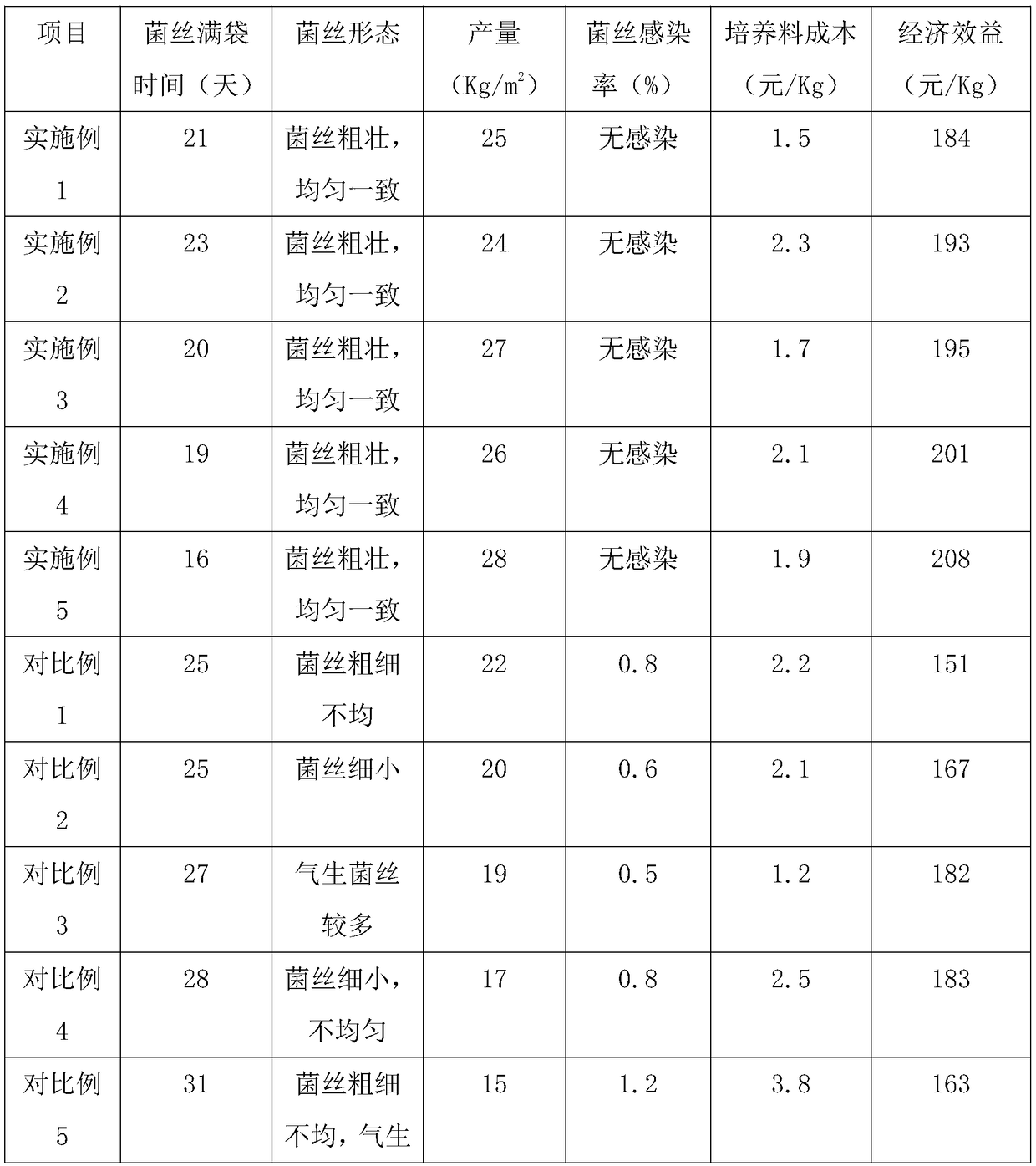

Examples

Embodiment 1

[0030] Present embodiment relates to a kind of preparation method of oyster mushroom compost, comprises the following steps:

[0031] (1) Take the following raw materials in parts by weight: 60 parts of straw, 30 parts of corn cob, 20 parts of bagasse, 25 parts of oil residue, 1 part of vitamin B, 10 parts of quicklime, 3 parts of protease, 1 part of ligninase, shell 1 part of polysaccharide, 15 parts of modified rice stone powder, 3 parts of potassium dihydrogen phosphate;

[0032] (2) putting straw, corn cob, bagasse and oil residue into a constant temperature drying box for drying, after drying, use a pulverizer to pulverize straw, corn cob, bagasse and oil residue into mixed particles with a diameter of 2cm;

[0033] (3) Put the mixed particles in the step (2) in the reaction box, add 1.2 times of water by weight of the mixed particles, then add quicklime, wait for the water to no longer produce air bubbles, add protease and lignin plum in the reaction box, After stirring...

Embodiment 2

[0044] Present embodiment relates to a kind of preparation method of oyster mushroom compost, comprises the following steps:

[0045] (1) Weigh the following raw materials in parts by weight: 80 parts of rice straw, 40 parts of corn cob, 30 parts of bagasse, 35 parts of oil residue, 3 parts of vitamin B, 18 parts of quicklime, 6 parts of protease, 5 parts of lignin, chitosan 3 parts of sugar, 20 parts of modified rice wheat stone powder, 8 parts of potassium dihydrogen phosphate;

[0046] (2) putting straw, corn cob, bagasse and oil residue into a constant temperature drying box for drying, after drying, use a pulverizer to pulverize straw, corn cob, bagasse and oil residue into mixed particles with a diameter of 2cm;

[0047] (3) Place the mixed particles in the step (2) in the reaction box and add 1.8 times of water by weight of the mixed particles, then add quicklime, wait for the water to no longer produce air bubbles, add protease and lignin plum in the reaction box, Aft...

Embodiment 3

[0058] Present embodiment relates to a kind of preparation method of oyster mushroom compost, comprises the following steps:

[0059] (1) Take the following raw materials by weight: 65 parts of rice straw, 32 parts of corn cob, 22 parts of bagasse, 27 parts of oil residue, 2 parts of vitamin B, 12 parts of quicklime, 4 parts of protease, 2 parts of ligninase, shell 2 parts polysaccharide, 17 parts modified rice wheat stone, 5 parts potassium dihydrogen phosphate;

[0060] (2) putting straw, corn cob, bagasse and oil residue into a constant temperature drying box for drying, after drying, use a pulverizer to pulverize straw, corn cob, bagasse and oil residue into mixed particles with a diameter of 2cm;

[0061] (3) Put the mixed particles in the step (2) in the reaction box, add 1.2 times of water by weight of the mixed particles, then add quicklime, wait for the water to no longer produce air bubbles, add protease and lignin plum in the reaction box, After stirring and mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com