Improved device for preparing polymer drug-loaded particles by supercritical antisolvent method

A supercritical anti-solvent and polymer technology, which is applied in the direction of coating particles, granulating raw materials, chemical instruments and methods, etc., can solve the problems of inability to achieve high-efficiency packaging of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

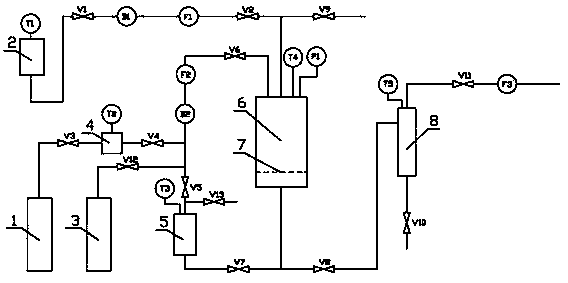

[0021] like figure 1 As shown, first close all valves of the device, add the ethanol solution dissolved with polylactic acid and paclitaxel into the solution storage tank 2, start the temperature control device of the solution storage tank 2, the cooling tank 4, the granulation tank 6, reach the set temperature Then open the third valve V3, the fourth valve V4, and the sixth valve V6, open the second high-pressure delivery pump B2, and pump carbon dioxide into the granulation tank 6. After reaching the predetermined temperature and pressure, open the first valve V1, the first valve Two valves V2, open the first high-pressure delivery pump B1, make the solution in the solution storage tank 2 enter the granulation tank 6 at a certain flow rate through the first flow control meter, open the ninth valve V9 and the eleventh valve V11 at the same time, use The supercritical carbon dioxide acts as an anti-solvent to obtain granules; after the granulation is completed, the first valve...

Embodiment 2

[0023] like figure 1 As shown, all valves of the device were closed first, Adefovir was added to the medicine tank 5, and the dichloromethane containing the polylactic acid-polyglycolic acid copolymer and the iron oxide nanoparticles surface-treated with oleic acid was added The solution is added to the solution storage tank 2, the temperature control devices of the solution storage tank 2, the cooling tank 4, and the granulation tank 6 are started, and the third valve V3, the fourth valve V4, and the sixth valve V6 are opened after reaching the set temperature, and the first valve is opened. The second high-pressure delivery pump B2 drives carbon dioxide into the granulation tank 6. After reaching the predetermined temperature and pressure, the first valve V1 and the second valve V2 are opened, the first high-pressure delivery pump B1 is turned on, and the first flow control meter is used to make the The solution in the solution storage tank 2 enters the granulation tank 6 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com