Mineral powder grinding aid for accelerating mineral powder hardening and preparation method thereof

A technology of grinding aid and mineral powder, which is applied in the field of mineral powder grinding, can solve the problems affecting the use efficiency of mineral powder and unsatisfactory hardness of mineral powder, so as to prevent the poor workability of mineral powder and fast hardening speed. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

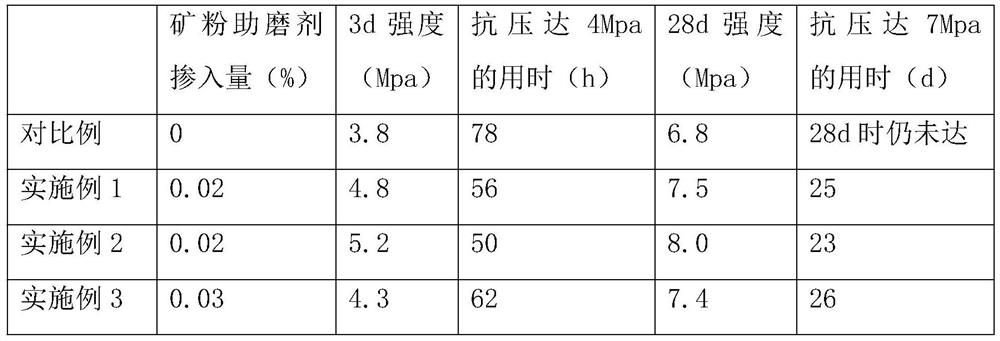

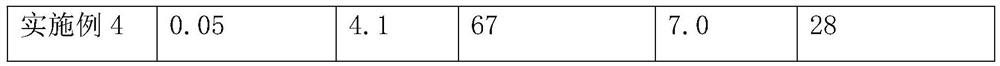

Embodiment 1

[0014] A mineral powder grinding aid for accelerating the hardening of mineral powder in this embodiment, at normal temperature, select the following raw materials in sequence according to the components by weight ratio, and make each component added until fully dissolved, and then add the next component Minute:

[0015] 20kg of water, 3kg of industrial salt, 3kg of sodium sulfate, 8kg of soda, 7kg of sodium nitrite, 6kg of urea, 1kg of sodium lignosulfonate, 8kg of triethanolamine, 40kg of complex alcohol amine, 2kg of glycerin, and 2kg of sugar. When grinding the ore powder, a mineral powder grinding aid for accelerating the hardening of the ore powder in this embodiment is added in an amount of 0.02% of the total amount of the ore powder to be ground. Among them, the complex alcohol amine is modified monoethanolamine and diethanolamine, and the industrial salt is the by-product salt of synthetic resin or untreated mineral salt and well salt.

Embodiment 2

[0017] A mineral powder grinding aid for accelerating the hardening of mineral powder in this embodiment, at normal temperature, select the following raw materials in sequence according to the components by weight ratio, and make each component added until fully dissolved, and then add the next component Minute:

[0018] 23kg of water, 5kg of industrial salt, 3kg of sodium sulfate, 5kg of soda, 6kg of sodium nitrite, 4kg of urea, 3kg of sodium lignosulfonate, 10kg of triethanolamine, 38kg of complex alcohol amine, 1kg of glycerin, and 2kg of sugar. When grinding the ore powder, a mineral powder grinding aid for accelerating the hardening of the ore powder in this embodiment is added in an amount of 0.02% of the total amount of the ore powder to be ground. Among them, the complex alcohol amine is modified monoethanolamine and diethanolamine, and the industrial salt is the by-product salt of synthetic resin or untreated mineral salt and well salt.

Embodiment 3

[0020] A mineral powder grinding aid for accelerating the hardening of mineral powder in this embodiment, at normal temperature, select the following raw materials in sequence according to the components by weight ratio, and make each component added until fully dissolved, and then add the next component Minute:

[0021] 23kg of water, 5kg of industrial salt, 4kg of sodium sulfate, 6kg of soda, 6kg of sodium nitrite, 4kg of urea, 3kg of sodium lignosulfonate, 10kg of triethanolamine, 37kg of complex alcohol amine, 1kg of glycerin, and 1kg of sugar. When grinding the ore powder, a mineral powder grinding aid for accelerating the hardening of the ore powder in this embodiment is added in an amount of 0.03% of the total amount of the ore powder to be ground. Among them, the complex alcohol amine is modified monoethanolamine and diethanolamine, and the industrial salt is the by-product salt of synthetic resin or untreated mineral salt and well salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com