Solid-wood composite floor surface board repairing method

A solid wood composite floor and surface board technology, which is applied in the joining of wooden veneers, adhesive types, wood processing appliances, etc., can solve the problems of low efficiency, restraining the enthusiasm of defective veneers, and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

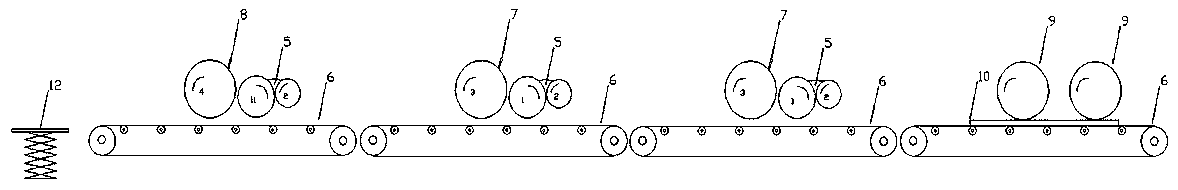

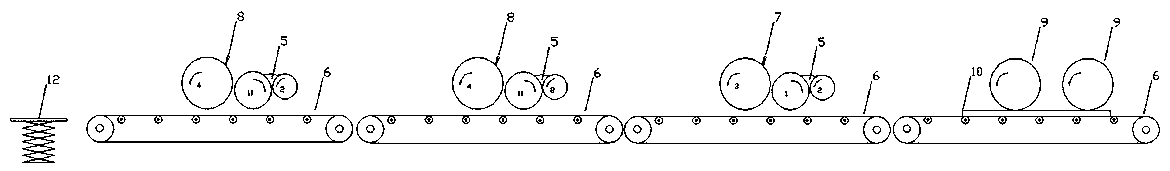

[0030] A method for repairing the solid wood composite floor surface. Firstly, the filling material 5 is prepared, and the mass ratio is raw glue: curing agent (ammonium chloride): flour: wood bran powder: iron powder = 100:3:10:11:0.8, and the filling The viscosity of the material is 19000cps, and the filler is injected into the roller coating equipment.

[0031] The substrate 10 with the surface plate attached has a specification of 1850×1220×15mm, and the surface plate is hickory veneer, which is transported to the polishing wheel 9 by the conveyor belt 6, and is pre-polished, and the impurities on the defect of the surface plate are brushed to make the surface plate The fracture at the defect is rougher, and the contact area with the filler is increased in the subsequent sequence, making it easier to fill and repair. The brush polishing wheel is a steel roller with nylon bristles planted on the shaft body. The nylon bristles are 40mm long and 1.5mm in diameter.

[0032] A...

Embodiment 2

[0036] A method for repairing solid wood composite floor surface boards, deploying filler 5, mass ratio raw glue: curing agent (ammonium chloride): flour: wood bran powder: iron powder = 100:3.1:12:10:0.8, filler The viscosity is 16000cps, and the filler is injected into the roller coating equipment.

[0037] The substrate 10 with the surface plate attached has a specification of 1200×1225×15mm, and the surface plate is oak veneer, which is transported to the polishing wheel 9 by the conveyor belt 6, and is pre-polished, and the impurities on the defect of the surface plate are brushed to make the surface plate The fracture at the defect is rougher, and the contact area with the filler is increased in the subsequent sequence, making it easier to fill and repair. The brush polishing wheel is a steel roller with nylon bristles planted on the shaft body. The nylon bristles are 40mm long and 1.1mm in diameter.

[0038] After polishing, when the substrate 10 with the surface plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com